Date: 2025-11-12

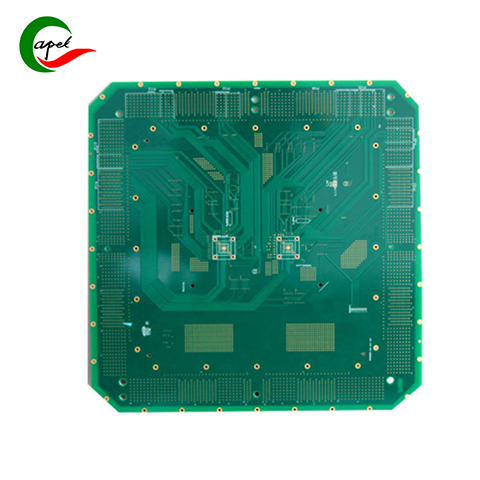

Let's talk about what it takes to make circuit boards that don't fail in your car or airplane. As demands get tougher, manufacturers like Caboer are stepping up with real solutions.

The Core Challenge:

We need boards that can handle extreme temperatures, brutal vibrations, and keep signals clean - all while lasting for decades.

1. Starting with the Right Stuff: Better Materials

The Base Material is Key:

For high-frequency signals like automotive radar or aircraft communications, standard materials just don't cut it. We're using specialized substrates that maintain stable electrical properties from -55°C to +150°C. While brands like Rogers and Taconic set the standard, we're also seeing competitive Chinese alternatives emerge.

Making Copper Work Harder:

Rolled copper is becoming essential because it bends without breaking during temperature swings. For surface finishes, we choose between ENIG for most automotive needs and the more robust ENEPIG for aerospace applications - always making sure we meet environmental standards.

2. Smarter Board Design

Tiny Holes, Big Impact:

Those microscopic holes you see in modern boards? They're game-changers. Using UV lasers, we can create perfectly clean holes as small as 0.08mm. This means shorter, cleaner signal paths with less electrical noise.

Keeping Signals Pure:

High-speed signals travel in carefully matched pairs, and we build in natural shielding - either embedded barriers or rings of grounding vias - to block interference from other electronics.

Hidden Components:

We're now burying tiny components inside the board itself. This makes everything more robust against vibration while saving precious space.

3. Manufacturing That Doesn't Cut Corners

Precision Drilling and Plating:

Our UV lasers create cleaner holes than older methods, and we pay extra attention to plating - we need perfect copper coverage inside those tiny holes with no weak spots.

Perfect Alignment:

With optical alignment systems, we ensure every layer lines up perfectly. Even microscopic misalignment can mean failed connections.

Building to Last:

Critical components get additional protection with underfill epoxy, and we reinforce high-stress areas like connectors to prevent cracking.

4. Proving We Can Take the Punishment

Brutal Testing:

Boards undergo extreme temperature cycling, prolonged vibration, and corrosion testing. We need to find the failure points before the boards reach the field.

Total Traceability:

We track every material batch and manufacturing step. If something goes wrong years later, we can trace it back to its source.

Built-in Backup:

For critical functions, we design redundant circuits - if one path fails, another takes over.

What Caboer Brings to the Table:

We've invested in the right equipment for today's challenges:

UV laser drilling for those critical microvias

Advanced plating systems for perfect copper coverage

Optical alignment for layer-to-layer precision

Automated inspection to catch issues early

We understand that different applications need different solutions. For automotive, we focus on vibration resistance and temperature cycling. For aerospace, we prioritize extreme temperature performance and radiation resistance.

We're working with material suppliers to find the right balance between performance and cost, including evaluating domestic alternatives that can reduce costs without compromising quality.

The Bottom Line:

Success in today's demanding applications comes down to three things: choosing the right materials, designing for the environment, and executing manufacturing with precision. At Caboer, we're focused on making boards that don't just work - they keep working under conditions that would destroy ordinary electronics.

We're building partnerships with automotive and aerospace companies to solve real-world challenges. Whether it's radar systems for autonomous vehicles or flight controls for aircraft, we're ready to help build what's next.

Want to discuss how we can help with your specific challenges? Let's talk about what your application really needs.

Capel manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..