CAPEL Prototyping Service

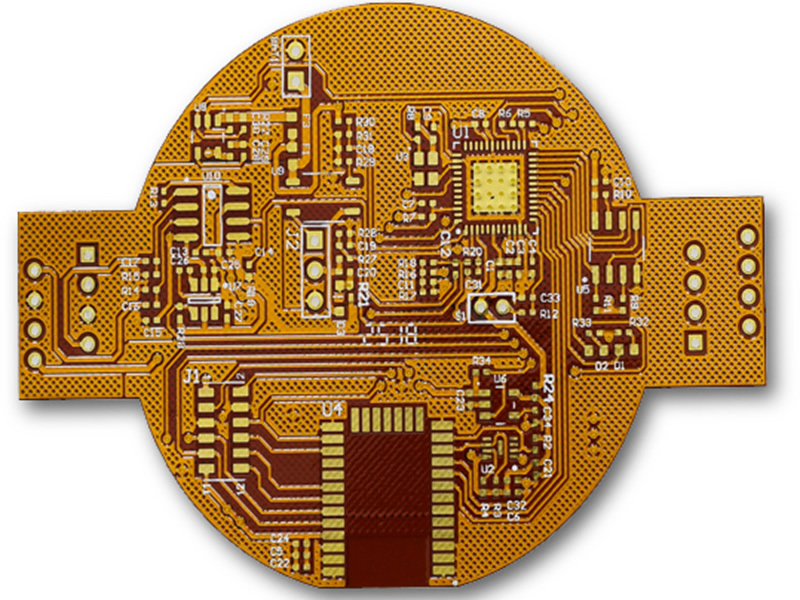

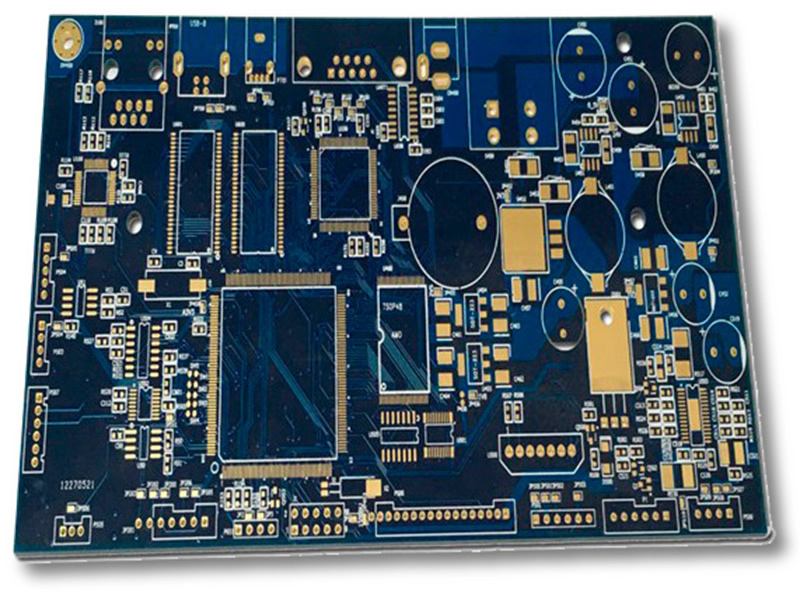

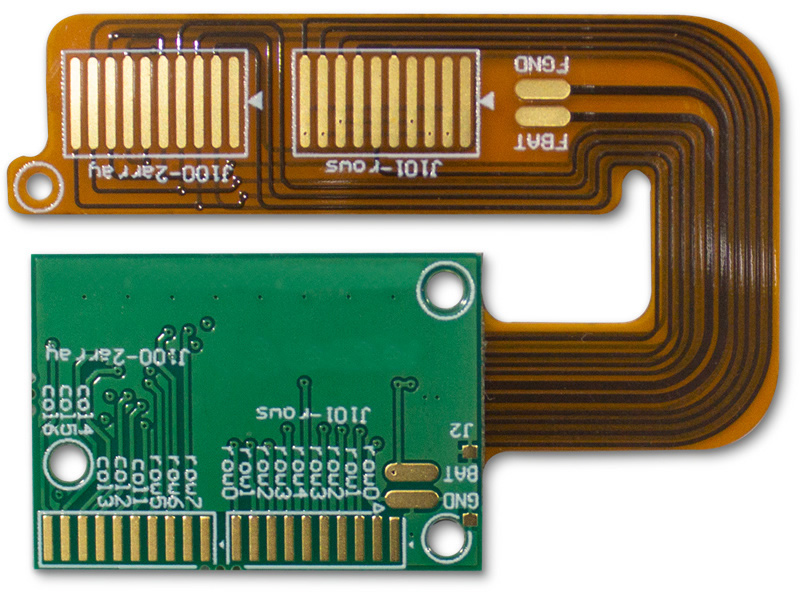

FPCs & PCBs & Rigid-Flex PCBs & SMT Assembly

Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCBs production capacity can reach 80000sqm per month, and Assembling capacity at 150,000,000 components per month.

Quick Turn Reliable PCB Prototyping

√ MOQ 1 piece

√ 24 Hours quick turn pcb prototype

√ 24x7 Online technical sales service

√ Gerber file evaluation before production

√ All-round and fast logistics service support

√ Laser-drilled microvias

√ via-in-pad

√ Design for Manufacturing(DFM) Checking

√ up to 60 layers

√ IPC Class 3 Standard

√ implementing ISO 9001, ISO 14001, 5S and 6Q standards

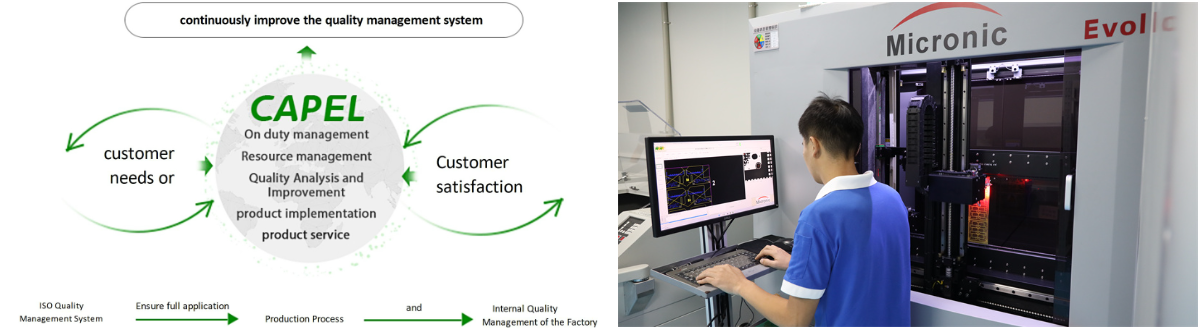

Quality Control

√ IQC(Incoming Quality Control)

√ IPQC(ln-process Quality Control)/FAl test

√ Visual Inspection after reflow oven/AOl

√ Visual Inspection before reflow oven

√ QA random inspection

√ OQC (Out-going Quality Control)

√ High tech PCB Assembly service(SMT/DIP line)

√ Professional components sourcing

√ Innovative programming and function test

PCB Assembly Service

√ SMT & PTH assembly

√ 1-2Days quick turn pcb assembly prototype

√ Fast response for technical support and advice

√ BOM analysis to ensure component uniformity and data integrity

√ Through Hole Board Assembly

√ Mixed Technology(SMT/Thru-hole)

√ Single or double sided placement

√ High pin count press fit capable Rigid,Flexible PCB and Rigid flex PCB Assembly

CAPEL Experience&Strength

√ Manufacturing PCBs since 2009

√ Strong R&D Team with 15 years experience

√ Customized up to 60 layers boards

√ Serviced cases involed in 100+ Field

√ Complete company system(own FPC/Rigid-Flex PCB factory, PCB factory, SMT factory)

√ Complete departmental structure (R&D Department, Engineering Department, Overseas Sales Department, Purchasing Department, Production Department, Process Department, Quality Department, Warehouse Management Department, Logistics Management Department, Overseas After-sales Service Department)

√ Strict and well-improved quality control system

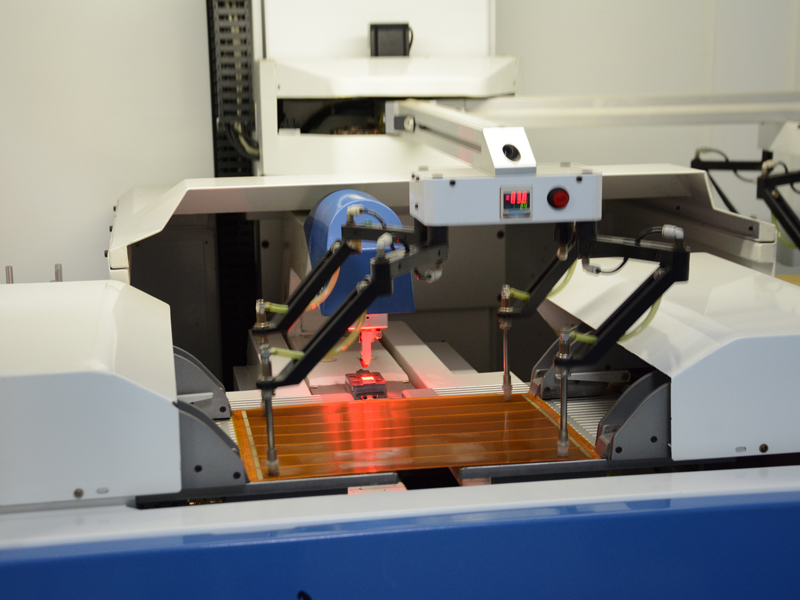

CAPEL's Strict Quality Control System

Every product produced by the company must undergo strict testing to ensure quality

CAPEL PCB Assembly Prototyping

Material Preparation→ Solder Paste Printing→ SPI→ IPQC→ Surface Mount Technology→ Reflow Soldering

↓

Protection and Packaging ← After Welding ← Wave Soldering ← X-ray ←AOI ← First Artide Testing

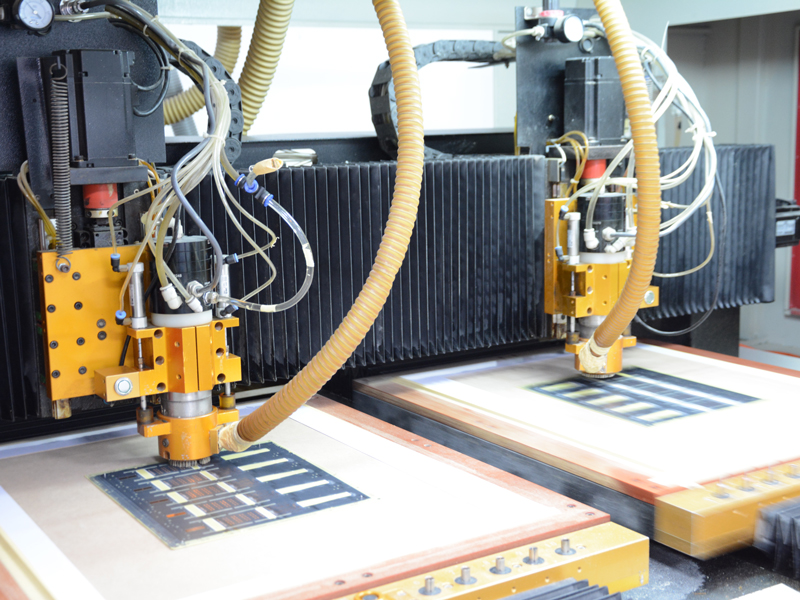

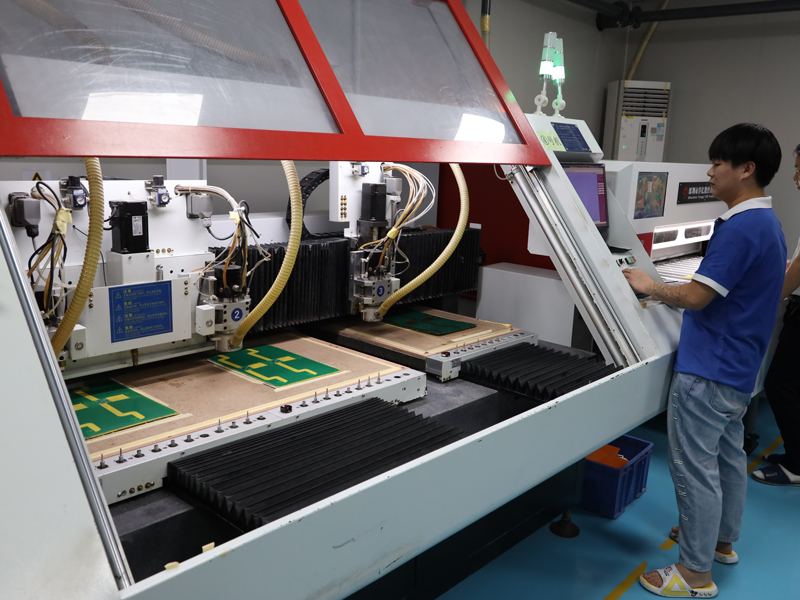

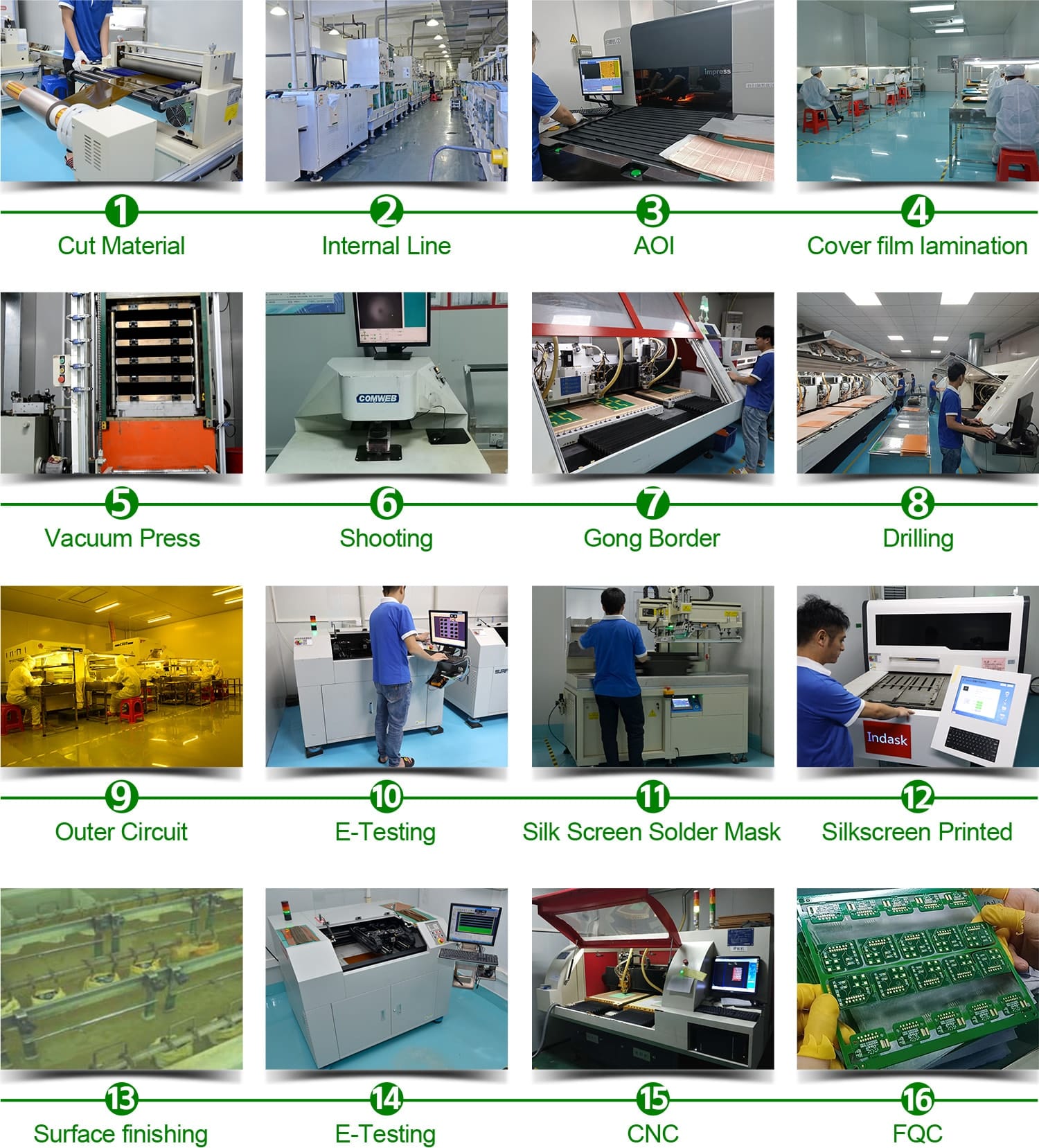

FPC Production Process

Rigid-Flex PCBs Production Process

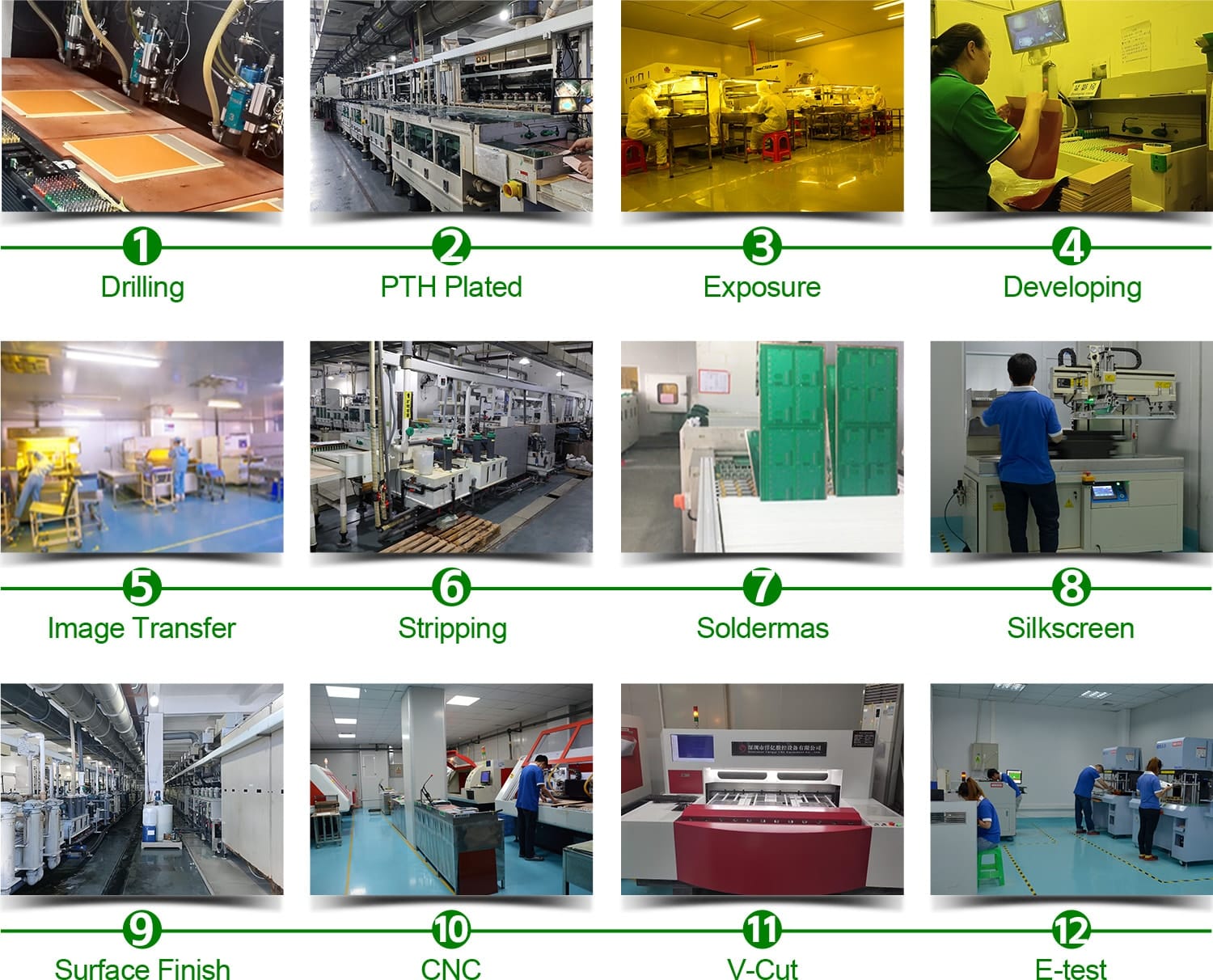

PCB Production Process

PCBA Production Process