High-Precision 4G GPS Tracker Flex PCB: The Core Engine of Advanced Tracking Solutions

Date: 2025-07-02

Abstract: Shenzhen Capel delivers ultra-thin, high-reliability Flex & Rigid-Flex PCBs for 4G GPS trackers. Featuring 0.03mm traces, 100K bend cycles, ±5% impedance control for centimeter-level accuracy. Ideal for fleet, asset, wearables & IIoT tracking.

In the era of IoT, real-time and accurate location data has become the lifeline for logistics, asset security, personnel monitoring, and specialized equipment management. 4G GPS trackers, as the nerve endings of this critical data, rely on the reliability, environmental adaptability, and miniaturization of their internal components—especially the high-precision flexible printed circuit boards (Flex PCBs) that handle signal transmission, power delivery, and data processing. With 15 years of expertise in mid-to-high-end PCB manufacturing, Shenzhen Capel Technology has emerged as a trusted core technology partner for global high-end 4G GPS tracker manufacturers, ensuring precision positioning.

Flex PCB: The Ultimate Solution for GPS Tracker Design Challenges

Traditional rigid PCBs struggle to meet the demanding requirements of modern 4G GPS trackers due to inherent limitations in space utilization, form adaptability, and mechanical stress resistance:

-

Space Constraints & Performance Bottlenecks: Integrating 4G LTE modules, multi-band GNSS receivers (GPS/GLONASS/Galileo/BeiDou), high-sensitivity antennas, large-capacity batteries, and sensors in compact spaces is challenging with rigid PCBs.

-

Vulnerability in Dynamic Environments: Vehicle vibrations, shocks, and repeated bending (e.g., wearables) can cause solder cracks or circuit breaks, leading to high failure rates.

-

Complex Form Factor Adaptation: Trackers must fit cylindrical (OBD devices), curved (wearables), or irregular spaces, which rigid boards cannot accommodate flexibly.

-

Weight & Size Limitations: For drones or portable devices, every gram counts—rigid PCBs add unnecessary bulk.

Capel’s Flex PCB solutions for high-end 4G GPS trackers combine ultra-precise manufacturing, unmatched reliability, and forward-thinking design:

-

Ultra-High-Density Interconnect (HDI) for Maximized Space Efficiency

-

Precision Circuitry: 0.03mm/0.035mm trace/space (surpassing industry standards of 0.1mm+), enabling complex 4G/GPS RF circuits and high-speed signal routing in minimal space.

-

Microvia Technology: 0.075mm (3mil) laser microvias ensure seamless layer transitions, reducing signal loss and enhancing high-frequency signal integrity for stable 4G LTE/GPS data transmission.

-

Ultra-Thin Design: 0.03mm thickness reduces weight and frees space for larger batteries, extending tracker uptime.

-

Exceptional Mechanical & Environmental Durability

-

100,000+ Bend Cycles: IPC-6013D-certified dynamic flex testing ensures reliability in wearables, asset tags, or OBD trackers.

-

Advanced Thermal Management: High-thermal-conductivity materials (e.g., PI substrates) dissipate heat from 4G/GNSS chips, preventing performance drift in -40°C to +85°C extremes.

-

10kV ESD Protection: Integrated ESD shielding safeguards sensitive GPS/4G modules from electrostatic damage.

-

High-Frequency & High-Speed Optimization for Pinpoint Accuracy

-

±5% Impedance Control: Tight tolerance for GPS L1/L5, BeiDou B1/B2, and 4G LTE signals, minimizing reflection/distortion to achieve centimeter-level positioning and high-speed data transfer.

-

Signal/Power Integrity (SI/PI): Optimized routing, ground planes, and decoupling capacitor placement reduce noise/crosstalk for stable high-speed digital signals.

-

Advanced Materials & Specialized Processes

-

26m Ultra-Long Flex PCBs: Proven capability for large-scale applications (e.g., aerospace, vehicle wiring).

-

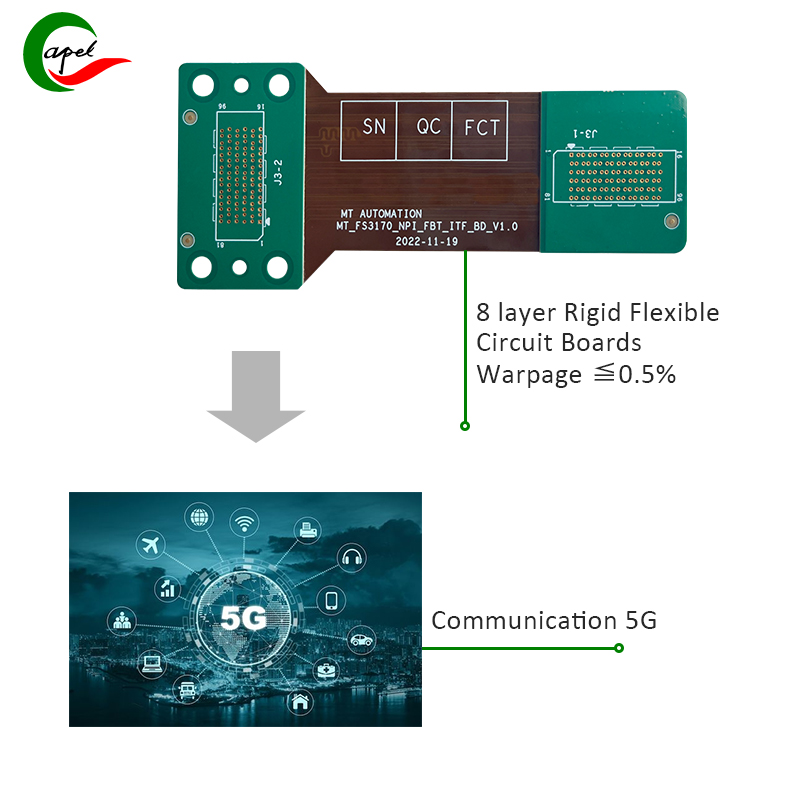

Rigid-Flex Solutions (2-32 layers): Combines high-density processing (rigid sections) with flexible installation (dynamic/folded areas).

-

Specialty Applications: Compliant with automotive (AEC-Q), medical, and industrial IoT standards for extreme environments.

Industry Applications: Precision Tracking, Powered by Capel PCBs

Why Choose Shenzhen Capel?

-

15+ Years Expertise: Specialized in 1-32L Flex PCBs, 2-32L Rigid-Flex, 14L HDI.

-

End-to-End Control: From DFM/DFT support to automated production and rigorous testing (impedance/bend tests).

-

Cutting-Edge Capabilities: 0.03mm traces, 0.075mm microvias, 0.03mm ultra-thin, 26m long flex PCBs.

-

Industry-Specific Solutions: Serving automotive, medical, IoT, smart home, and aerospace sectors.

Unlock Your Design Potential! Contact (https://www.capelfpc.com/)Shenzhen Capel today for custom Flex/Rigid-Flex PCB solutions tailored to your 4G GPS tracker—and lead the next era of advanced tracking technology!