Date: 2025-12-22

Circuit board component labels, also known as silkscreen markings or legend printing, are the alphanumeric identifiers printed directly onto a PCB's surface that help engineers, assemblers, and technicians identify components, test points, and orientation during manufacturing, testing, and repair. These labels serve as the permanent "instruction manual" on the board itself, containing vital information that ensures correct assembly and facilitates troubleshooting throughout the product's lifecycle.

In high-volume electronics manufacturing, clear and accurate circuit board component labels are not just convenient—they're essential for operational efficiency and quality control. They directly impact:

Assembly Accuracy: Prevents component placement errors during SMT and through-hole assembly

Testing Efficiency: Allows technicians to quickly locate test points and measurement nodes

Rework and Repair: Enables precise component replacement during debugging and field service

Quality Documentation: Provides traceability for compliance and failure analysis

Supply Chain Management: Facilitates component verification during incoming inspection

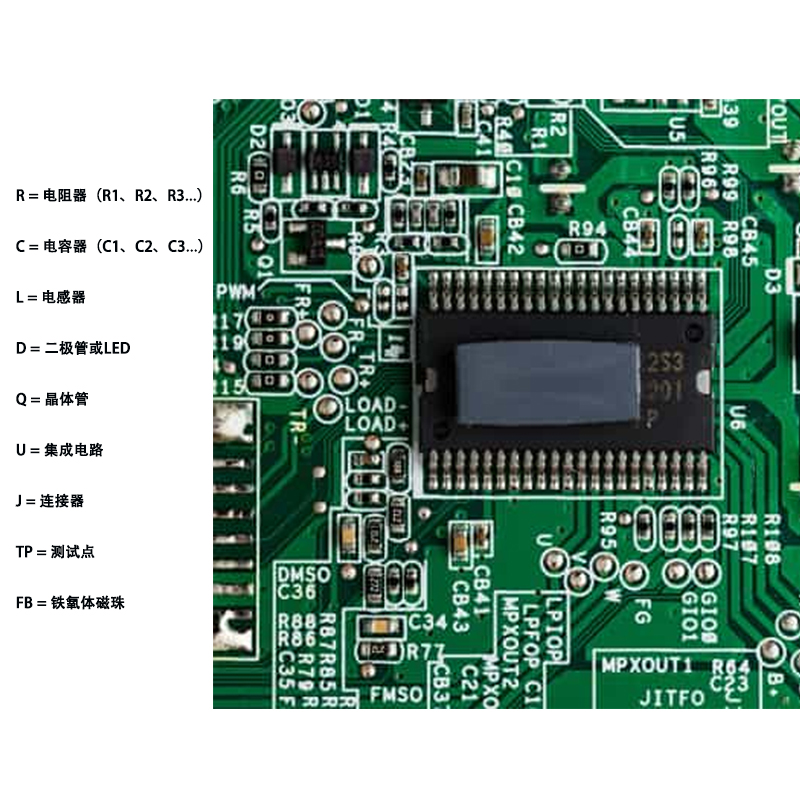

The most fundamental circuit board component labels follow industry-standard naming conventions:

R = Resistor (R1, R2, R3...)

C = Capacitor (C1, C2, C3...)

L = Inductor

D = Diode or LED

Q = Transistor

U = Integrated Circuit

J = Connector

TP = Test Point

FB = Ferrite Bead

Critical for preventing assembly errors:

Diodes/Capacitors: Cathode marking, "+" for polarized capacitors

ICs: Pin 1 indicator (dot, notch, or beveled corner marking)

Connectors: Pin 1 designation

Power Inputs: "+" and "−" or "VCC"/"GND" designations

Company logos and certifications (CE, UL, RoHS symbols)

Date codes and revision numbers

Warning symbols (high voltage, ESD sensitivity, thermal warnings)

Board name and part number

The IPC (Association Connecting Electronics Industries) provides specifications for circuit board component labels:

IPC-2221/2222: General design standards including labeling requirements

IPC-2610: Defines preferred silkscreen letter sizes and line widths

Minimum Legibility: Text height should generally be ≥0.8mm for manual assembly, though advanced assembly lines with vision systems can work with smaller text

Legibility Requirements:

Text Height: Minimum 0.5mm for machine-readable, 0.8mm for human-readable

Line Width: Minimum 0.15mm for reliable printing

Clearance: Maintain 0.25mm minimum between text and pads/vias/solder mask openings

Contrast: White epoxy ink on green solder mask is standard, but other color combinations are possible

Placement Rules:

Never place labels under components

Avoid placing over holes or vias

Keep labels away from soldering areas

Ensure labels remain visible after component placement

Issue: Labels too close to pads or vias get obscured by solder or cause assembly confusion.

Solution: Maintain minimum 0.25mm clearance between text and any copper feature. Use automated DRC (Design Rule Check) tools to verify spacing.

Issue: Ambiguous or missing polarity indicators cause component reversal during assembly.

Solution: Use standard symbols consistently. For ICs, always mark Pin 1 with both a dot on the pin and a corresponding indicator in the silkscreen.

Issue: Text smaller than 0.5mm becomes illegible after printing or during reflow.

Solution: Establish minimum font sizes in your design rules. Consider separate labeling layers for machine-vision-only markings.

Issue: Components without labels increase assembly time and error rates.

Solution: Ensure every component has a unique reference designator. Automated BOM verification tools can help identify missing labels.

For boards requiring enhanced durability or special environmental resistance, UV-curable inks offer superior adhesion and chemical resistance compared to standard epoxy inks.

An alternative to traditional silkscreening, laser marking etches labels directly into the solder mask or copper. Benefits include:

Extremely fine resolution (text as small as 0.2mm)

Excellent durability and thermal resistance

No ink bleed or smearing

Environmentally friendly (no inks or solvents)

For traceability requirements, some manufacturers implement unique serial numbers or QR codes on each board, allowing individual unit tracking throughout the supply chain.

Place Labels Before Finalizing Layout: Consider label placement early in the design process, not as an afterthought.

Group Related Labels: Cluster labels for related components to improve readability.

Consistent Orientation: Keep all text oriented the same way (preferably 0° or 90°) for easier reading.

Layer Strategy: Consider using both top and bottom silkscreen layers, but ensure bottom-layer text doesn't interfere with assembly.

Be Succinct: Use standard abbreviations and avoid unnecessary text.

Prioritize Critical Information: Ensure polarity, orientation, and safety warnings are most prominent.

Version Control: Include revision identifiers that change with each design iteration.

International Considerations: Use symbols rather than words when possible for global products.

Modern SMT lines increasingly rely on circuit board component labels for machine vision guidance:

Fiducial Marks: Specialized markings (typically circular or cross-shaped) that help assembly machines precisely align the board.

Barcode/QR Code Reading: Automated scanning of board identifiers for process control and tracking.

Component Verification: Vision systems can cross-check placed components against nearby labels for validation.

At Kaboer, we understand that clear, accurate circuit board component labels are fundamental to manufacturing quality and efficiency. Our approach ensures every board we produce provides maximum clarity for assembly and service:

Design Review Expertise:

Our engineering team performs comprehensive labeling checks during our DFM (Design for Manufacturability) analysis. We'll identify potential issues such as:

Text too close to pads or vias

Missing or ambiguous polarity markings

Insufficient text size for your assembly method

Inconsistent labeling conventions

Advanced Printing Capabilities:

Our Shenzhen manufacturing facility employs high-precision silkscreen printing with:

0.1mm minimum line width capability

Automatic optical alignment for perfect registration

Choice of standard or high-contrast ink colors

Optional laser marking for high-density or durable applications

Quality Verification:

We don't just print labels—we verify them. Our quality checks include:

Automated optical inspection of label clarity and positioning

Manual verification against your assembly drawings

Consistency checks across production panels

For international electronics manufacturers, our attention to these details means fewer assembly errors, faster troubleshooting, and higher overall product quality. Whether you're producing prototypes or high-volume runs, properly executed circuit board component labels are one of the many details we manage to ensure your boards are not just functional, but optimally manufacturable and serviceable.

Emerging technologies may enable embedded RFID or other tracking technologies within the board itself, providing more data than visible markings alone.

AR systems could use physical labels as anchors to display interactive repair instructions or real-time diagnostic data during service.

Developments in ink technology may lead to labels that change color with temperature or other environmental factors, providing built-in status indicators.

Start Early: Consider labeling requirements during initial layout, not as a final step.

Follow Standards: Adhere to IPC guidelines and industry conventions.

Prioritize Clarity: Ensure critical markings (polarity, orientation, warnings) are most prominent.

Test Legibility: Verify that labels remain readable in actual use conditions.

Document Conventions: Maintain a labeling standard document for consistency across projects.

Circuit board component labels represent a critical intersection of design, manufacturing, and serviceability. While often overlooked in favor of more complex electrical considerations, effective labeling directly impacts manufacturing yield, testing efficiency, field service costs, and ultimately, product reliability. By investing proper attention to labeling design and implementation, electronics manufacturers can significantly reduce errors, streamline operations, and deliver higher quality products to market.

Whether you're designing your first prototype or optimizing a high-volume product, remember that clear communication through effective circuit board component labels is as important to your product's success as the circuitry itself. Partnering with a manufacturer like Kaboer that understands and implements professional labeling practices ensures this fundamental aspect receives the attention it deserves.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..