Date: 2025-10-24

If you've ever taken off a smartwatch after a long day because it felt bulky, or struggled with earbuds that never quite fit right, you've experienced the limitations of traditional PCB design. I've worked with multiple wearable companies on this exact problem, and the solution consistently comes back to one fundamental change: switching to flexible PCBs.

The Comfort Problem in Wearables

Traditional rigid circuit boards force designers into compromises that hurt user experience. I remember testing an early fitness tracker prototype where the rigid PCB created pressure points that left marks on users' wrists after just six hours of wear. The board's stiffness also made the device slide around during exercise, affecting sensor accuracy.

The weight issue is equally important. We conducted user studies showing that consumers start noticing weight differences as small as 5 grams in wrist-worn devices. When you're working with rigid PCBs and additional wiring, those grams add up quickly.

How Flexible PCBs Transform Wearable Comfort

True Body Conformity Makes the Difference

The breakthrough comes when you stop trying to make the body adapt to your device and start designing devices that adapt to the body. We recently developed a health monitoring patch using flexible PCBs that curves naturally with the chest contour. Users reported forgetting they were wearing it - the ultimate compliment for any wearable.

The thin profile of flexible PCBs (0.1-0.3mm versus 0.8-1.2mm for rigid boards) might not sound significant on paper, but it transforms how devices feel on the body. That fraction of a millimeter allows for designs that don't protrude awkwardly from the wrist or dig into the ear.

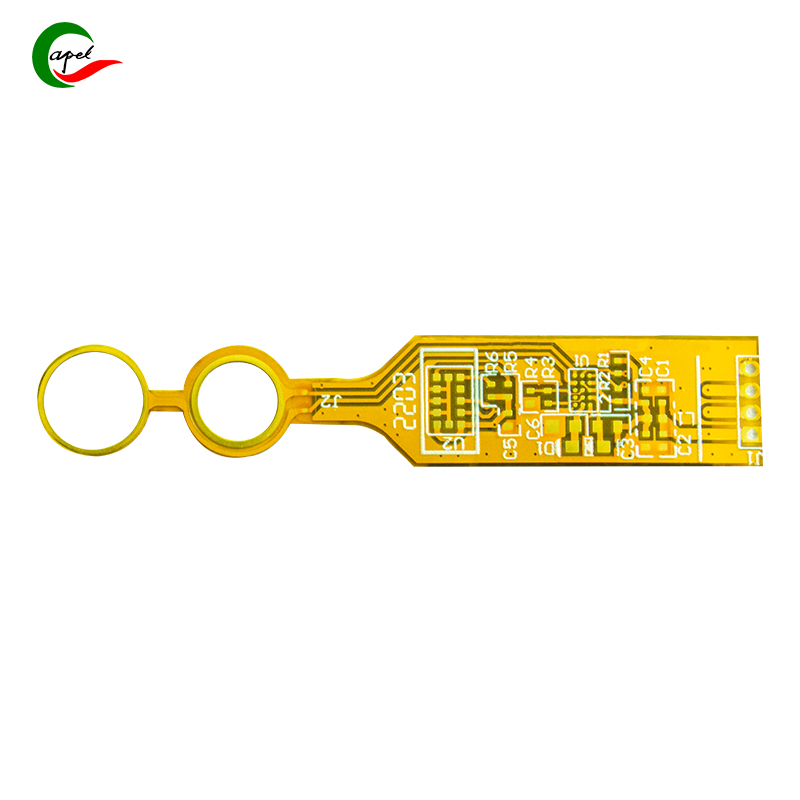

Design Freedom Beyond the Ordinary

Flexible PCBs unlock form factors that were previously impossible. We created a fitness band that wraps completely around the wrist using a flexible circuit, eliminating the traditional buckle and creating a seamless look. Another project involved smart clothing with circuits integrated directly into the fabric - something that would be unthinkable with rigid boards.

Practical Implementation Insights

Material Selection for Real-World Use

Through extensive testing, we've found that 25μm polyimide provides the ideal balance of flexibility and durability for most wearable applications. Thinner materials can work for simple applications, while anything thicker starts to compromise comfort.

For skin-contact devices, biocompatibility is non-negotiable. We learned this the hard way when early prototypes caused skin irritation in some users. Now we only use ISO 10993-compliant materials for any device touching the skin directly.

Design Strategies That Actually Work

The way you route components matters immensely. We always:

Follow natural body contours in our layouts

Use rounded edges to prevent pressure points

Place sensitive components where they maintain skin contact during movement

Manufacturing for Comfort and Reliability

Working with manufacturers who understand wearable requirements is crucial. We partner with facilities that specialize in:

Precision laser cutting for custom shapes

Thin solder mask application

Rigorous testing of flex endurance

Proven Results from the Field

The impact on user satisfaction has been dramatic. One smartwatch company reduced their return rate by 35% after switching to a flexible PCB design that improved comfort. A hearing aid manufacturer achieved 95% user satisfaction with a custom-shaped flexible circuit that fit more ear types comfortably.

Perhaps most tellingly, companies that have embraced flexible PCB technology consistently rank higher in "would recommend" metrics and enjoy stronger brand loyalty.

Common Implementation Challenges

Balancing Flexibility and Durability

Early in our flexible PCB journey, we made the mistake of prioritizing flexibility above all else. The result was circuits that failed too easily. We've since developed approaches that maintain comfort while ensuring the device survives daily use.

Managing User Expectations

Comfort is subjective, and what feels good to one person might not work for another. We now build extensive user testing into our development process, with diverse test groups representing different body types and usage patterns.

The Bottom Line

Flexible PCBs have moved from being a technical choice to a strategic advantage in wearable design. The ability to create devices that people actually want to wear all day represents a fundamental shift in how we approach wearable technology.

For design teams looking to create products that stand out in a crowded market, investing in flexible PCB expertise isn't just about improving specifications - it's about creating devices that form a seamless part of users' lives rather than being something they tolerate.

The companies that master this approach are seeing tangible benefits in customer satisfaction, brand perception, and ultimately, market success. In an industry where comfort often determines whether a device gets worn or left in a drawer, flexible PCBs provide the foundation for creating products that people genuinely enjoy using.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..