FPC Flex Circuit Manufacturers for Consumer Electronics

Date: 2025-08-02

FPC (Flexible Printed Circuits) have become indispensable in consumer electronics, thanks to their unique advantages like bendability and ultra-thinness. As the consumer electronics market expands and product categories diversify, FPC manufacturers face a landscape brimming with both opportunities and challenges.

Market Dynamics: Opportunities Fueled by Growth

The steady expansion of the consumer electronics market directly drives demand for FPCs. From smartphones and wearables to AR/VR devices and home appliances, the growing variety of products demands FPCs that are increasingly versatile in design and manufacturing.

Navigating Challenges: Innovation as the Core

To thrive in this competitive space, FPC manufacturers must prioritize technical advancement and process optimization to deliver high-quality, high-performance solutions:

-

Precision Manufacturing: Achieving consistent thinness and layer alignment demands advanced equipment (e.g., laser drilling, automated inspection systems) and strict process controls to minimize defects like short circuits or signal interference.

-

Material Science: Selecting durable, heat-resistant substrates (e.g., polyimide) and conductive materials ensures FPCs withstand repeated bending, high temperatures, and harsh operating environments—critical for devices like gaming consoles or automotive infotainment systems.

-

Speed to Market: With consumer electronics cycles shortening (e.g., annual smartphone releases), manufacturers need agile R&D and production workflows to iterate designs quickly and meet tight delivery timelines.

Kaboer has positioned itself as a key player in consumer electronics FPCs by focusing on innovation, quality, and customer collaboration:

-

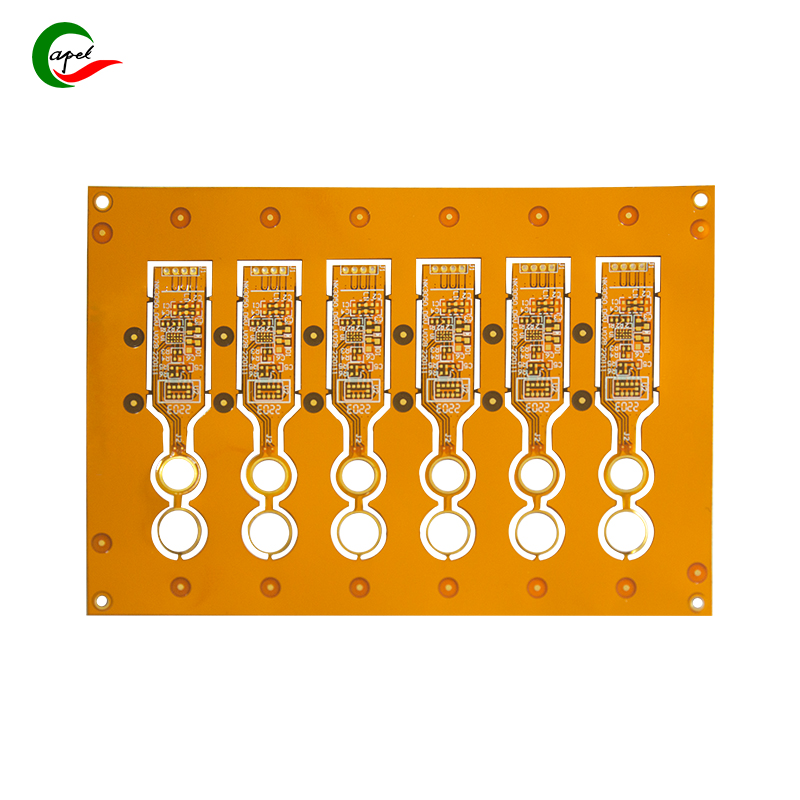

Technical Innovation: The company invests in R&D to develop ultra-thin FPCs (as thin as 0.08mm) and high-layer-count designs (up to 16 layers), addressing the needs of next-gen devices like foldable smartphones and compact IoT sensors.

-

Manufacturing Excellence: By adopting automated production lines and precision machinery, Kaboer reduces production costs while improving consistency—critical for mass-market consumer electronics.

-

Customer-Centric Solutions: Working closely with clients, Kaboer tailors FPCs to unique device specifications, whether optimizing flexibility for wearable bands or enhancing signal integrity for 5G-enabled gadgets.

-

Stringent Quality Control: A robust quality management system ensures every FPC undergoes rigorous testing (e.g., thermal cycling, bend endurance) to meet industry standards, building trust with brands and consumers alike.

Conclusion

The consumer electronics boom presents vast opportunities for FPC manufacturers, but success hinges on the ability to innovate, adapt, and deliver value. By prioritizing technical upgrades, flexible production, and customer collaboration—like Kaboer—manufacturers can not only meet the evolving demands of the market but also drive the next wave of innovation in consumer electronics.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.