Date: 2025-11-20

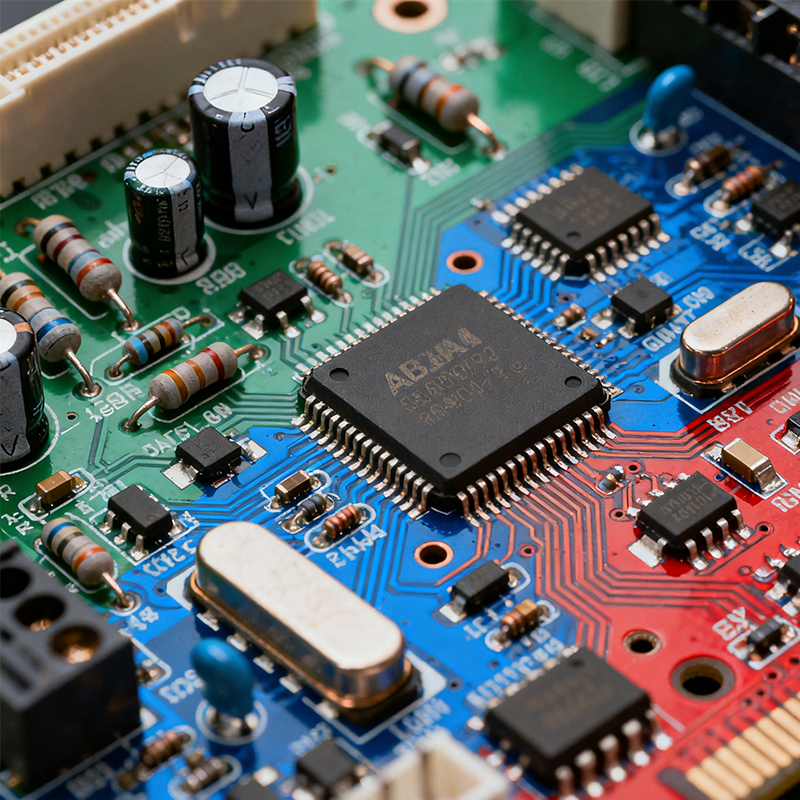

Here's the truth about electronics: heat kills. Whether you're building industrial power supplies, automotive systems, or high-performance computing gear, if you can't manage the heat, your product will fail. It's not a matter of if - it's when.

The secret to reliable high-temperature PCBA design isn't complicated: get the heat out, and use parts that can take the heat. You need to move heat away from sensitive components and make sure everything can handle the temperatures it will actually experience.

Part 1: Smart PCB Design - Your First Line of Defense

Think of your PCB as the foundation of your thermal management system. Get this right, and everything else gets easier.

Thicker Copper = Better Heat Spreading

Use heavy copper (2-3oz) for power paths - it's like building a wider highway for both electricity and heat

Design traces wide enough to handle the current without cooking themselves

For big power components, create generous thermal pads with plenty of vios down to inner layers - this gives heat an escape route

Layout Matters - Don't Cluster Hot Components

Spread out heat-generating parts like power transistors and converters

Keep temperature-sensitive components like sensors and processors away from hot spots

Think about airflow during layout - don't block the natural cooling paths

Choose the Right Board Material

Standard FR4 works until about 85°C - then you need high-temperature versions

For serious heat, aluminum core boards move heat 3-10 times better than regular FR4

In really tough applications, nothing beats copper for pure heat spreading capability

Part 2: Getting Heat Out - Your Cooling Toolkit

Sometimes smart PCB design isn't enough. Here's how we help heat find its way out.

Passive Cooling (Simple & Reliable)

Heat sinks attached to hot components can drop temperatures by 15-30°C

Sometimes just exposing copper areas to air does the trick

For spreading heat across larger areas, thermal spreaders work wonders

When You Need Serious Cooling Power

Small fans can increase cooling effectiveness 5-8 times over natural convection

For the toughest jobs, liquid cooling plates can keep components below 80°C even in brutal environments

Heat pipes are like super-highways for moving heat away from tight spaces

Don't Forget the Interface Materials

Thermal pads and pastes fill gaps between components and heat sinks

Choose materials that can handle your temperature range long-term

Some conformal coatings actually help with heat dissipation instead of blocking it

Part 3: Choosing Components That Can Take the Heat

The best cooling system won't save components that weren't built for high temperatures.

Power Components Built for Heat

Look for power ICs, MOSFETs, and IGBTs rated for 125°C and above

Choose packages designed for heat dissipation - ones with built-in thermal pads or tabs

Remember: better thermal packaging can be more important than raw specifications

Don't Let Passive Components Be Your Weak Link

Standard electrolytic capacitors die young in hot environments - use polymer or ceramic instead

Metal film and alloy resistors handle heat much better than carbon film

Connectors need high-temperature plastics and reliable contacts

Processors and Complex ICs

Industrial and automotive-grade chips are worth the extra cost for high-temperature applications

Lower power versions generate less heat to begin with

Always leave yourself some temperature headroom - don't run components at their absolute limits

Part 4: Making It Work in the Real World

Designing for heat is one thing - making sure it actually works is another.

Simulate Before You Build

Thermal simulation tools can spot problems before you ever build a board

Test your design under worst-case conditions, not just ideal scenarios

Identify hot spots and component temperatures in software first

Build It Right

Make sure thermal vias aren't filled with solder during assembly

Use high-temperature hardware for mounting heat sinks and other thermal management parts

Thermal cycling tests will reveal weak solder joints and other assembly issues

Test What You Built

Infrared cameras show you exactly where heat is building up

Long-term high-temperature testing proves your design will last

Measure actual component temperatures under real operating conditions

The Bottom Line

We've seen boards fail from heat. We've also learned how to make boards that survive in environments that would cook ordinary electronics.

Whether you're dealing with the heat inside an industrial motor drive, an automotive power system, or high-power LED lighting, the principles are the same: move heat away from sensitive components, and use parts that can handle the temperatures they'll experience.

The good news? You don't need to figure this out alone. We've helped companies solve thermal challenges in everything from factory automation to electric vehicles. We know what works, what doesn't, and how to get you to a reliable solution faster.

Ready to build electronics that can take the heat? Let's talk about your thermal challenges and how we can help you solve them.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..