PCB Selection in Automotive Millimeter-Wave Radar: High-Frequency Performance Optimization Tips for FPC/Rigid-Flex Boards

Date: 2025-08-26

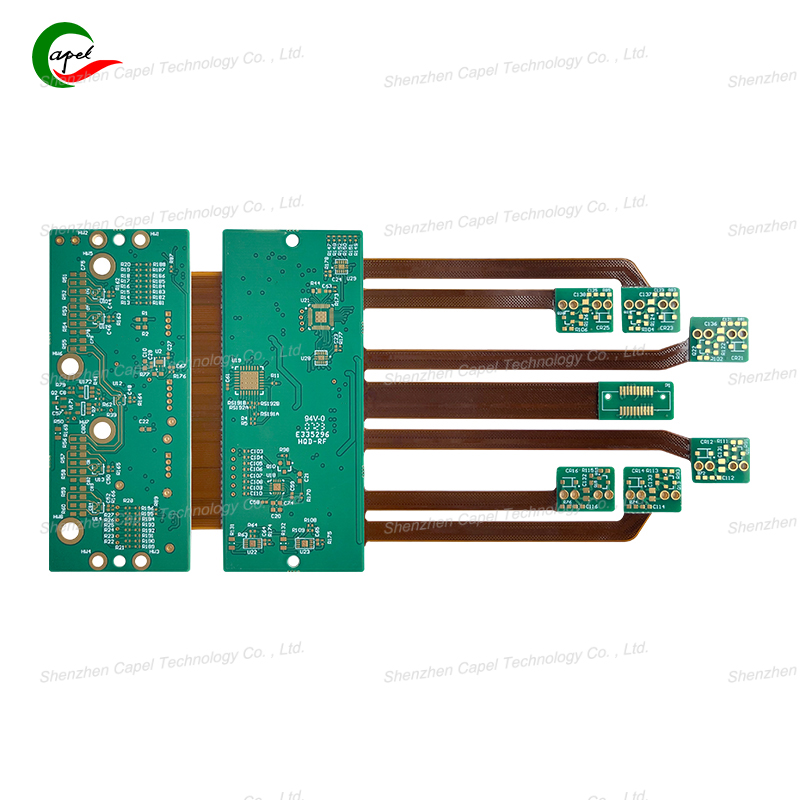

Automotive millimeter-wave radar—critical for ADAS features like adaptive cruise control and collision avoidance—relies on PCBs to transmit high-frequency signals (76–81 GHz) with minimal loss. For tight spaces in radar modules, FPCs and rigid-flex boards are top choices—but their high-frequency performance needs careful tuning. Here are actionable optimization tips.

High-frequency signals fade fast in poor substrates. For FPCs, use polyimide with low dielectric loss (Df < 0.002 at 80 GHz)—like DuPont’s Kapton HN. It keeps signal attenuation low, even in the radar’s compact layout. Rigid-flex boards need matching rigid layers: choose FR-4 variants with ceramic fillers (e.g., Isola FR408HR) to align dielectric constants (Dk) between rigid and flexible parts, avoiding signal reflection.

Millimeter-wave signals are sensitive to noise. For FPCs, use microstrip lines with narrow trace widths (0.15–0.2 mm)—this reduces parasitic capacitance. Keep traces short: a 1mm longer trace can increase loss by 0.3 dB at 80 GHz. For rigid-flex boards, place high-frequency traces on flexible sections only when needed; rigid layers offer better stability for critical paths. Also, add ground planes close to signal traces (distance < 0.1mm) to shield against interference from nearby power lines.

Radar modules require 50Ω impedance for signal integrity. For FPCs, adjust trace width and substrate thickness: a 0.18mm trace on 0.125mm thick Kapton hits 50Ω. For rigid-flex boards, use laser drilling for vias (diameter < 0.3mm) to avoid impedance jumps—traditional drilling can widen holes, disrupting signal flow. Test impedance with a network analyzer post-production to catch deviations.

Real-World Win: Bosch’s latest radar modules use optimized rigid-flex boards. By pairing Kapton FPC layers with low-loss rigid substrates and 0.18mm microstrip lines, they cut signal loss by 20%—boosting radar detection range by 5 meters.

Poor PCB performance can make radar misdetect obstacles. With these tips, FPCs and rigid-flex boards deliver the reliability ADAS needs—while fitting in tight radar enclosures.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.