In the fast - paced world of electronics, where innovation seems to happen at the blink of an eye, the choice of printed circuit boards (PCBs) plays a crucial role in enabling the rapid iteration and upgrade of devices. Two types of PCBs that have gained significant attention in this regard are rigid - flex PCBs and modular PCBs. Each has its own set of characteristics, advantages, and limitations, making the decision between them a complex one for electronics manufacturers.

The Marvel of Rigid - Flex PCBs

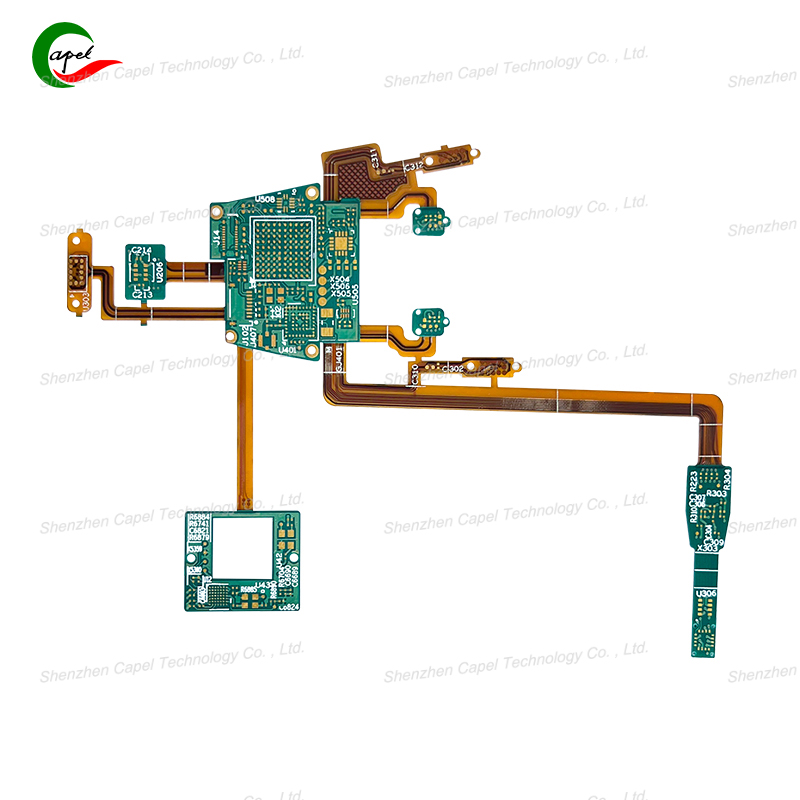

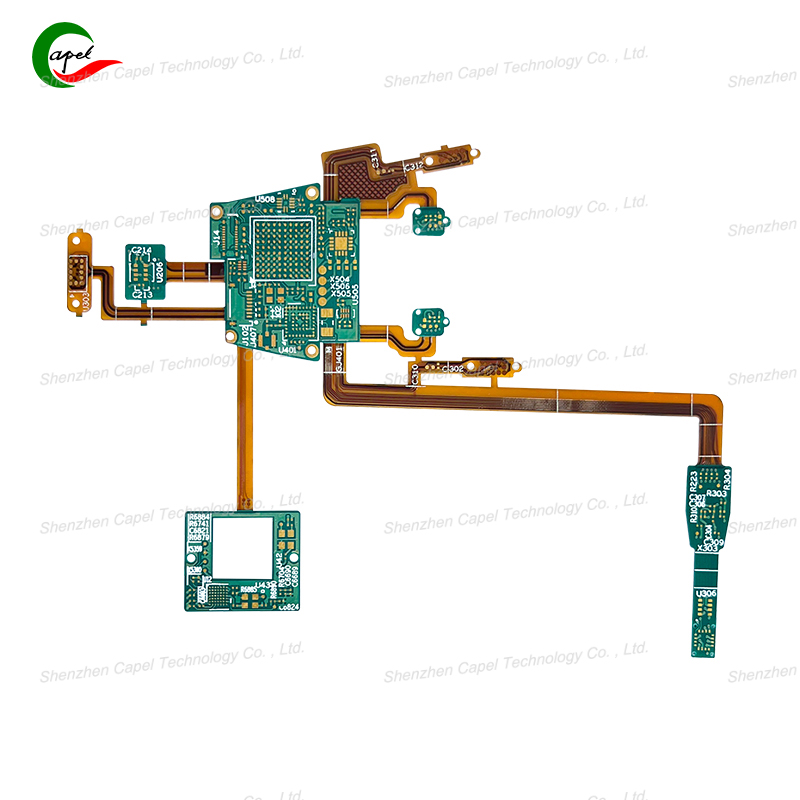

Flexibility Meets Stability

Rigid - flex PCBs, as the name implies, combine the features of rigid and flexible circuit boards. The rigid sections, often made of materials like FR - 4, provide a stable base for mounting components and ensuring structural integrity. On the other hand, the flexible parts, typically crafted from polyimide, offer the ability to bend, twist, and conform to complex shapes. This unique combination is a game - changer in many applications. For instance, in wearable electronics such as smartwatches, the rigid - flex PCB allows for a compact design where the flexible part can wrap around the wrist comfortably, while the rigid part houses important components like the processor and battery. This not only saves space but also enhances the overall aesthetics and functionality of the device.

Enhanced Design Freedom

One of the major advantages of rigid - flex PCBs in the context of rapid iteration is the design flexibility they offer. Designers can create intricate 3D layouts, which are essential for modern, space - constrained electronic devices. In a smartphone, for example, the rigid - flex PCB can be designed to connect various components such as the camera module, display, and motherboard in a way that maximizes the use of available space. This ability to design complex, customized circuits means that manufacturers can quickly adapt to changing market demands and technological advancements. New features can be added or existing ones optimized without having to completely overhaul the PCB design, reducing both time and cost associated with product development.

High Reliability in Challenging Environments

Rigid - flex PCBs are known for their high reliability, even in harsh environments. The flexible sections can absorb vibrations and shocks, protecting the components mounted on the rigid parts. In automotive electronics, where the PCB has to withstand constant vibrations from the engine and rough road conditions, a rigid - flex PCB can ensure the stable operation of components like sensors and control units. This reliability factor is crucial for electronic devices that need to function flawlessly over an extended period, as it reduces the likelihood of product failures and recalls, which can be costly in terms of both reputation and finances.

The Allure of Modular PCBs

Plug - and - Play Advantage

Modular PCBs are designed with a building - block approach. Each module is a self - contained unit that performs a specific function, such as a power module, a communication module, or a processing module. This modular design allows for easy integration and replacement. In a home security system, for example, if the wireless communication module needs to be upgraded to support a new protocol, it can be simply unplugged and replaced with a newer, more advanced module. This “plug - and - play” feature significantly reduces the time and effort required for product upgrades. Manufacturers can quickly introduce new features or improve existing ones by swapping out the relevant modules, rather than redesigning the entire PCB.

Scalability and Customization

Modular PCBs offer excellent scalability. Whether a product needs to be scaled up for mass production or scaled down for a more compact version, the modular design makes it easier. A manufacturer producing a range of smart home hubs can use the same base modular PCB and simply add or remove modules depending on the target market and feature set. For high - end models, additional modules for advanced voice control and extended connectivity can be included, while for more budget - friendly versions, some non - essential modules can be omitted. This scalability not only speeds up the product development process but also allows for better cost control, as resources can be allocated more efficiently.

Faster Time - to - Market

In the highly competitive electronics industry, time - to - market is often a key determinant of success. Modular PCBs can help manufacturers achieve this goal more quickly. Since each module can be developed and tested independently, parallel development becomes possible. A team can work on the power module while another team focuses on the sensor module. Once all the modules are ready, they can be assembled into a complete PCB. This reduces the overall development time compared to designing a monolithic PCB from scratch. For example, a startup developing a new fitness tracker can use pre - designed and pre - tested modular PCBs to get their product to market faster, giving them a competitive edge in the market.

A Comparative Analysis

Design Complexity and Iteration Speed

When it comes to design complexity, rigid - flex PCBs can be more challenging to design initially due to their need for careful consideration of both rigid and flexible sections. However, once designed, they offer great flexibility for minor design changes and upgrades. Modular PCBs, on the other hand, have a more straightforward design concept based on the modular approach, which can be easier to understand and modify. In terms of iteration speed, modular PCBs have an edge in scenarios where a major change in functionality is required. For example, if an electronic device needs to switch from using a Wi - Fi 4 module to a Wi - Fi 6 module, it is much quicker to replace a modular Wi - Fi module than to redesign a rigid - flex PCB to accommodate the new component.

Manufacturing Costs and Yield

Rigid - flex PCBs generally have higher manufacturing costs. The combination of rigid and flexible materials, along with the more complex manufacturing processes involved in bonding them together, contributes to this higher cost. Additionally, the yield (the percentage of successfully manufactured PCBs) can be lower due to the difficulty in ensuring the quality of both the rigid and flexible sections. Modular PCBs, while having their own manufacturing costs associated with producing individual modules, can be more cost - effective in the long run, especially for products with a high volume of production. The ability to reuse modules across different product lines also helps in reducing costs. However, if the number of modules in a product is large, the overall cost of procurement and assembly can increase.

Compatibility and Integration

Rigid - flex PCBs are highly customized for a specific device, which can limit their compatibility with other products. Once designed for a particular smartphone model, for example, it may not be easily adaptable for use in a different brand or model. Modular PCBs, on the contrary, are designed with compatibility in mind. Standardized interfaces between modules make it possible to mix and match modules from different manufacturers, promoting innovation and competition in the module - making market. This compatibility also simplifies the integration process, as manufacturers can choose the best - performing modules for their products without having to worry about major compatibility issues.

Real - World Examples

Case 1: Smartphones

In the smartphone industry, rigid - flex PCBs have been widely used. Apple's iPhones, for instance, utilize rigid - flex PCBs to achieve a sleek and compact design. The ability to bend the PCB allows for better use of the limited space inside the phone, enabling the integration of multiple components such as the battery, camera, and display in a more efficient manner. However, when it comes to upgrading certain features, such as the camera module, the process can be more complex and time - consuming as it may require a redesign of the rigid - flex PCB. In contrast, some modular smartphones, although not as widespread, offer the advantage of easy upgradability. The Fairphone, for example, is designed with a modular approach, allowing users to replace components like the battery, camera, and display module as technology advances. This not only extends the lifespan of the phone but also reduces electronic waste.

Case 2: Industrial Automation

In industrial automation, both rigid - flex and modular PCBs find applications. In robotic arms used in manufacturing plants, rigid - flex PCBs are often used due to their ability to withstand vibrations and provide reliable connections in a harsh industrial environment. The flexible sections can bend as the robotic arm moves, ensuring stable communication between different sensors and actuators. However, for industrial control systems that need to be easily upgraded or customized for different production lines, modular PCBs are a popular choice. A factory that manufactures different types of products may use a modular PCB - based control system. As the production requirements change, new modules can be added to the system to control additional machinery or to implement new production processes.

Conclusion

In conclusion, the choice between rigid - flex PCBs and modular PCBs for the rapid iteration and upgrade of electronic devices depends on a variety of factors. Rigid - flex PCBs are ideal for applications where space is at a premium, high - reliability in challenging environments is crucial, and the design can be optimized for a specific product with relatively minor changes over time. Modular PCBs, on the other hand, shine in scenarios where quick and easy upgrades, scalability, and compatibility are the top priorities. Electronics manufacturers need to carefully evaluate their product requirements, cost constraints, and market demands before making a decision. In many cases, a combination of both technologies may also be a viable solution, leveraging the strengths of each to achieve the best results in the ever - evolving world of electronics.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.