Date: 2025-10-20

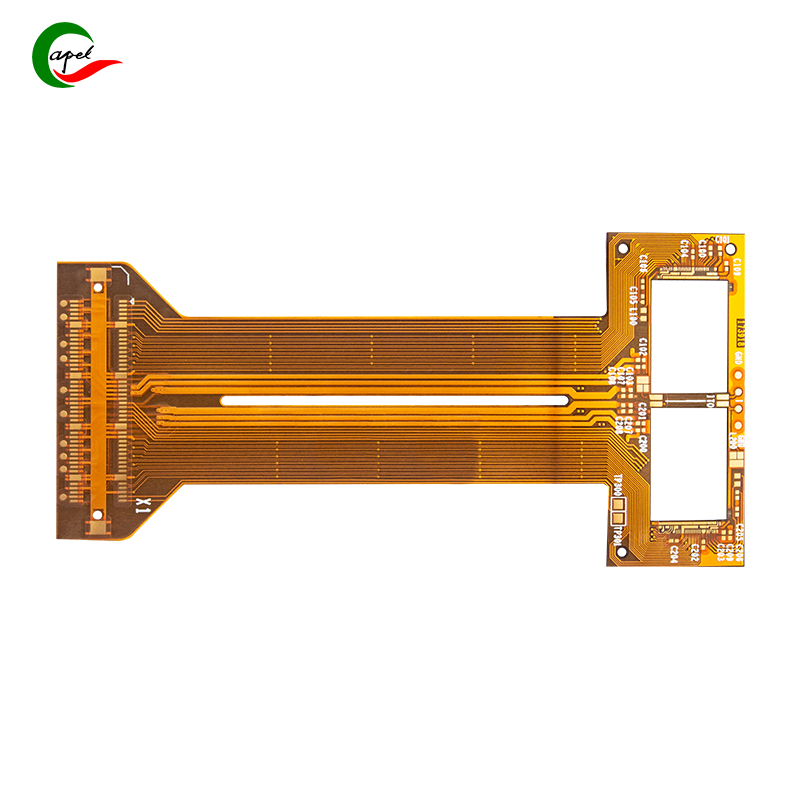

If you've ever found yourself squinting through a microscope at a 0.4mm-pitch flex PCB, watching in horror as solder bridges form between pads, you're not alone. Bridging and cold solder joints are the twin nightmares of micro-soldering, capable of slashing your production yield by 20% or more.

The good news? After a decade on the production floor, I've found that consistent success doesn't require a million-dollar lab. It boils down to nailing four key areas: solder paste selection, stencil design, thermal profiling, and obsessive cleanliness. Let's cut through the theory and get into the practical steps that actually move the needle.

First, you need to know your enemy. Micro pads aren't just smaller versions of regular pads; they play by a different set of rules.

Zero Room for Error: With gaps between pads often less than 0.3mm, a single extra solder particle can create a short. It's a volumetric tightrope walk.

The Flex Substrate Works Against You: Polyimide (PI) is a terrible conductor of heat. This makes it incredibly easy to create cold joints (not enough heat) or delaminate the board and lift pads (too much heat).

Contamination is a Giant Killer: A fingerprint, a speck of dust, or minor oxidation that a larger pad could tolerate will completely ruin the solder wetting on a micro pad, leading to a weak, non-sticky connection.

Placement Has to be Perfect: A misalignment of even 0.1mm can push solder paste onto the solder mask or an adjacent pad, guaranteeing a bridge.

Here’s the step-by-step playbook we use to tackle these issues on our line.

1. Solder Paste: It's All About the Particle Size

This is your first and most critical choice. Using the wrong paste is like trying to thread a needle with a piece of rope.

Forget Type 3. Go with Type 4 or Type 5. The finer powder (20-38μm for Type 4, 10-20μm for Type 5) flows cleanly through tiny stencil apertures and drastically reduces the risk of clogging and solder balling—the main precursors to bridging.

Opt for a Higher Flux Percentage. Look for a paste with 10-12% flux. That extra flux activity is crucial for cleaning the tiny pad surfaces and ensuring proper wetting, which is your best defense against cold joints.

Measure Religiously with SPI. You can't control what you don't measure. A Laser Solder Paste Inspector (SPI) is non-negotiable. For micro-pads, we target a deposit volume of 0.8 to 1.0 times the pad area and reject any board where the volume deviates by more than ±15%. Skipping this is flying blind.

2. Stencil Design: Your Blueprint for Success

A smart stencil design solves problems before the board even hits the reflow oven. This is where you win the war on bridging.

Thinner is Better. Ditch the standard 100-120μm stencils. For micro-pads, use a 50-75μm thick stencil. This single change is the most effective way to reduce paste volume and prevent overflow.

Use Reduced Apertures. Never make the stencil holes the same size as the pads. We typically reduce them to 80-90% of the pad size. For a 0.5mm pad, a 0.42mm aperture works beautifully.

Demand Trapezoidal Walls. Ask your stencil supplier for laser-cut, electro-polished apertures that are slightly wider at the bottom than the top (trapezoidal cross-section). This geometry ensures a clean, consistent paste release, leaving behind a perfect brick instead of a messy clog.

3. The Thermal Dance: Profiling for Flex PCBs

This is where you separate the pros from the amateurs. You need a profile that's hot enough to melt the solder but cool enough to protect the delicate flex material.

Preheat Slowly and Deliberately. A rapid temperature spike is your enemy. Take a full 60-90 seconds to ramp up to about 120-150°C. This gives the flux time to activate properly and drives off moisture without thermally shocking the polyimide.

Hit the Sweet Spot, Not the Roof. Your peak temperature should be just high enough—typically 30-40°C above the solder's liquidus point (220-235°C for SAC305). Crucially, you must stay below 240°C to avoid delaminating the board or causing pad lifting. Hold at peak for 30-45 seconds to ensure full wetting.

Control the Cooldown. A rapid quench (over 4°C/second) creates thermally stressed, brittle joints. A controlled, slower cool-down rate is essential for joint durability, especially on a material that will flex in use.

Use Nitrogen if You Can. For the toughest, smallest-pitch designs (≤0.4mm), running the oven with a nitrogen atmosphere (O₂ ≤ 500ppm) is a game-changer. It gives you shinier, stronger joints with significantly less chance of bridging by preventing oxidation during the critical reflow phase.

4. No-Compromise Cleanliness and Placement

Small errors become giant problems on micro pads. This is where discipline makes all the difference.

Clean the Pads Right Before Use. Wipe the pads with a lint-free wipe and 99% Isopropyl Alcohol immediately before the stencil is applied. For boards with any shelf life that might have oxidation, a mild acid cleaner followed by a thorough deionized water rinse is a must.

Placement Precision is Non-Negotiable. Use a pick-and-place machine with better than 0.05mm accuracy. Then, don't just trust the machine. Do a quick visual check under a microscope before reflow to catch any misaligned components. A two-second correction now saves a 20-minute rework later.

The "It's Just a Stencil" Mentality: Using a standard-thickness stencil with 1:1 apertures is a guaranteed recipe for a bridging disaster.

Skipping the SPI: Assuming your paste volume is fine without measuring it is accepting a 15-20% hidden defect rate from the start.

Blasting the Heat: The "crank it up to make sure it flows" approach is a great way to destroy flexible PCBs. More heat is not the answer.

Ignoring the Cooldown: The soldering process isn't over when the peak temperature is hit. How the joint solidifies is critical to its long-term reliability.

After reflow, your inspection regimen needs to be sharp.

Microscope Inspection (50-100x): Look for shiny, concave fillets that cover the pad completely. No bridges, no dull or grainy surfaces (a classic sign of cold solder).

Electrical Test: A simple multimeter continuity check can instantly find bridges. Measuring joint resistance can reveal poor connections that might look okay visually.

Pull Test (for critical parts): Applying a small, calibrated force (1-2 Newtons) can confirm the mechanical strength of the joint and expose any adhesion issues.

At the end of the day, consistent success with flexible PCB micro soldering isn't magic. It's a disciplined system: Fine-powder paste + a smart, thin stencil + a gentle, controlled thermal profile + fanatical cleanliness and placement.

Get this system right, and you'll watch your yields jump from frustrating to fantastic, building miniaturized products that are truly reliable. Now go forth and solder with confidence.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..