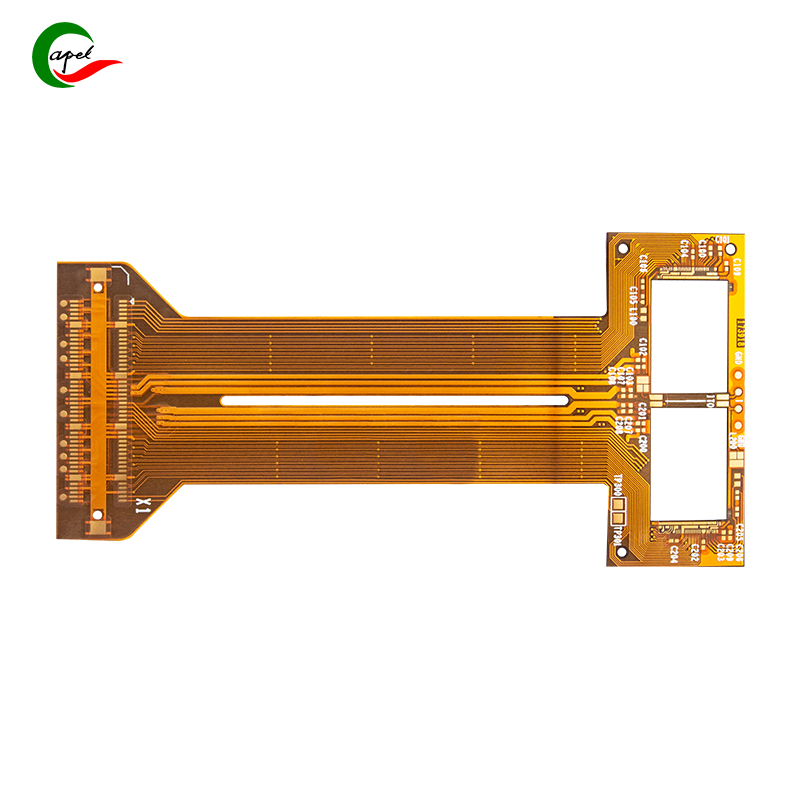

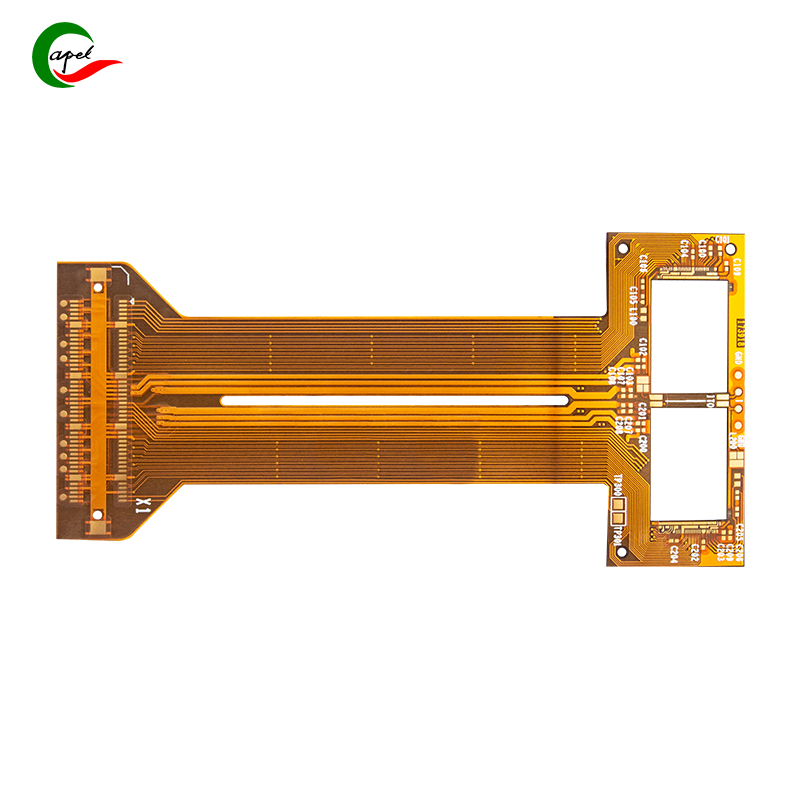

For 10 years, we’ve watched clients stress over FPCs: the ones that don’t fit their cases, the ones that crack after 500 bends, the ones that arrive 2 weeks late for a launch. We get it—when your FPC fails, your whole project fails. That’s why we don’t just sell FPCs. We act like your team’s backup: catching mistakes before they happen, fixing issues fast, and making sure your FPCs work for your design, not against it.

Here’s what we do differently—and how we’ve helped 300+ clients turn FPC headaches into smooth launches.

Last month, a client sent us Gerber files for a tiny smartwatch FPC. At first glance, the design looked fine—but when our engineer overlapped it with the 3D case model they provided, we noticed the FPC was 0.15mm too wide. It would’ve gotten stuck in the case, and they would’ve had to reorder 500 boards.

This is how we prevent that:

-

We don’t just take your files—we review them. Our team checks if your FPC fits your case, aligns with component footprints, and has enough space for bending. If something’s off, we flag it within 24 hours.

-

We offer free design tweaks. For that smartwatch client, we narrowed the FPC by 0.15mm—no extra cost. They got the revised prototypes 3 days later, and they fit perfectly.

-

We ask for details others don’t. “What’s the thickness of your battery?” “Will the FPC bend around a component?” These small questions stop big problems. A hearing aid client once forgot to mention their sensor protruded—we adjusted the FPC’s cutout, and it worked.

A fitness brand came to us after their previous supplier’s FPCs started cracking in smart bands—they were getting 60% returns. We asked one question: “Were those FPCs made with PET or PI?” Turns out, the old supplier used PET (cheaper, but not durable for daily bending).

Here’s how we make FPCs that hold up:

A medical device client called us panicking: their previous supplier missed a deadline, and they needed 200 FPCs in 48 hours for a regulatory test. If they missed the test, their launch would be delayed 3 months.

This is how we pulled it off:

-

We keep key materials in stock. PI 基材,ED/RA copper, conformal coating—we have them on hand, so we don’t wait for deliveries.

-

We prioritize urgent projects. For that medical client, we shifted production to fit their order. Our team worked overtime to print, coat, and test the FPCs—they arrived with 6 hours to spare.

-

We give clear timelines (and stick to them). When you order, we tell you exactly when prototypes and mass production will ship. If there’s a delay (rare!), we let you know within hours and offer a solution—like expedited shipping for free.

A lot of suppliers ship your boards and disappear. Not us. Last quarter, a client noticed a small signal issue with their FPCs 5 days after delivery. They called us at 7 PM, and our engineer got on a call 30 minutes later.

This is our promise to you:

-

You get a dedicated account manager. No more “I’ll transfer you to the team”—one person handles your project from start to finish. They know your design, your deadline, and your needs.

-

We help troubleshoot. If your FPCs have an issue (and if it’s our fault), we replace them for free—fast. For that signal issue, we sent revised FPCs in 3 days, no extra charge.

-

We follow up. A month after you receive your FPCs, we check in: “How’s everything working?” “Do you need adjustments for your next order?” We want to grow with you, not just sell you one batch.

We know choosing an FPC supplier is a risk. But it doesn’t have to be. We’re the supplier that catches your mistakes, builds FPCs that last, delivers on time, and sticks around. Whether you’re a startup with a new wearable or a big brand launching a foldable, we’ll make sure your FPCs don’t just work—they help you launch faster, with fewer headaches.

Ready to stop stressing about FPCs? Send us your design today. We’ll review it for free, share a clear quote, and get your prototypes out in 3–5 days. Let’s make your next project a success.