Date: 2025-12-29

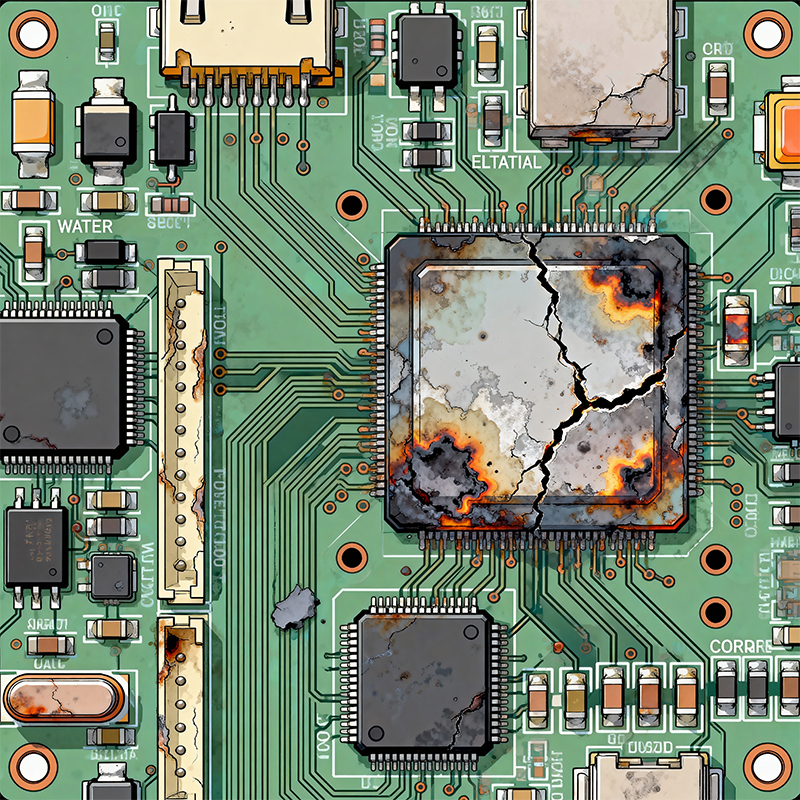

Circuit board failures are rarely random; they are typically the result of specific physical, electrical, or environmental stresses. Understanding these primary damage mechanisms is crucial for electronics manufacturers to design for reliability, implement effective quality control, and perform accurate root cause analysis. While the "most" damaging factor depends on context, the following categories represent the most common and severe causes of PCB failure.

Electrical overstress involves exposing the board to electrical conditions beyond its design limits, causing immediate or latent damage.

Overvoltage & Voltage Spikes (Transients): Exceeding the breakdown voltage of semiconductors (ICs, transistors, diodes) causes catastrophic gate oxide breakdown or junction burnout. This often occurs from electrostatic discharge (ESD), inductive load switching, or power supply faults.

Overcurrent: Excessive current, typically from a short circuit, leads to severe Joule heating. This can melt thin copper traces, vaporize PCB laminates, cause components to literally explode, or desolder themselves. Fuses are designed to prevent this.

Latch-Up: A parasitic short-circuit condition in CMOS ICs triggered by voltage spikes or ionizing radiation, leading to high current draw and thermal destruction if not power-cycled quickly.

Heat is a primary accelerator of failure. Damage can be sudden from extreme heat or accumulate over time from repeated cycles.

Excessive Operating Temperature: Operating components (like processors or power regulators) or the entire board near or above their rated temperature accelerates electrochemical reactions. This leads to faster component aging, increased leakage currents, and degradation of the PCB substrate itself.

Poor Thermal Design: Inadequate heat sinking or ventilation causes localized hotspots, leading to the failure of specific components even if the ambient temperature seems acceptable.

Thermal Cycling: Powering a device on and off, or environmental temperature swings, causes repeated expansion and contraction. This induces mechanical fatigue, leading to cracked solder joints (especially under large components like BGAs or connectors), delamination of PCB layers, and broken internal vias.

Physical force can cause immediate, catastrophic failure or create micro-cracks that lead to intermittent faults later.

Bending or Flexing: Forcing a rigid board to bend, often during handling or assembly into a tight enclosure, can crack surface traces, internal layers, and solder joints. This is a critical concern for large or thin boards.

Vibration: Sustained vibration in automotive, industrial, or aerospace applications can loosen mechanical fasteners and cause fatigue failure in solder joints and component leads.

Impact Shock: Dropping a device or subjecting it to a sharp impact can fracture ceramic capacitors, dislodge components, or cause immediate trace fractures.

The operating environment introduces agents that slowly degrade the board's integrity.

Moisture Ingress: Humidity or liquid spills lead to electrochemical migration. Dendrites (metal filaments) grow between oppositely charged conductors, causing current leakage and short circuits. Moisture also accelerates corrosion of exposed metal.

Contaminants & Dust: Ionic contaminants (e.g., salts from fingerprints, flux residues) on the board surface, combined with moisture, create conductive paths and cause leakage currents and corrosion. Non-conductive dust can insulate heatsinks and cause overheating.

Corrosive Atmospheres: Exposure to industrial gases, salt spray, or sulfur-containing environments can rapidly corrode copper traces and component leads, increasing resistance and eventually causing open circuits.

Flaws introduced during fabrication or assembly are latent defects waiting to fail under stress.

Poor Solder Joints: Cold solder joints (weak, grainy connections) or insufficient solder create high-resistance points that overheat. Solder bridging creates direct shorts.

PCB Fabrication Flaws: Plating voids in vias reduce current capacity and can crack. Inadequate etchback or drill misregistration can weaken the connection between layers.

Component Defects: Using out-of-spec, counterfeit, or aged components guarantees premature failure under normal operating conditions.

| Damage Category | Primary Physical Mechanism | Typical Visible Signs | Failure Mode |

|---|---|---|---|

| Electrical Overstress | Dielectric breakdown, Joule heating. | Burnt/charred components, exploded ICs, melted metal. | Catastrophic, sudden. |

| Thermal Stress/Cycling | Material fatigue, diffusion, chemical degradation. | Cracked solder joints, discolored PCB, bulging capacitors. | Gradual or intermittent. |

| Mechanical Stress | Fracture, delamination, plastic deformation. | Broken traces, cracked components, loose connectors. | Sudden or vibration-induced. |

| Environmental | Electrochemical migration, oxidation, corrosion. | Green/blue corrosion (copper salts), dendrites, white residue. | Gradual, often conductive. |

Design Stage: Implement proper derating for components, robust power conditioning (TVS diodes, filters), thermal management (heatsinks, thermal vias), and conformal coating for environmental protection.

Manufacturing Stage: Enforce strict ESD controls, use Automated Optical Inspection (AOI) and X-ray to catch solder defects, and ensure thorough cleaning to remove flux residues.

Testing & Validation: Conduct Environmental Stress Screening (ESS), including thermal cycling and vibration tests, to precipitate latent defects before shipment.

Handling & Operation: Follow proper ESD protocols, avoid mechanical stress during installation, and ensure the end-use environment is within specified limits.

Q1: Is electrostatic discharge really that damaging to modern circuit boards?

A: Yes, absolutely. Modern semiconductors with nanometer-scale features are incredibly sensitive to ESD. A discharge invisible to humans can easily exceed the breakdown voltage of a CMOS gate, causing immediate failure or a latent defect that weakens the component, leading to premature failure in the field.

Q2: Can a circuit board be repaired after physical trace damage?

A: It depends on the extent. A single broken trace on an outer layer can often be repaired with a jumper wire. However, cracks in internal layers, delamination, or damage to multi-layer vias are typically not repairable in a reliable, production-worthy manner. The board is usually considered a loss.

Q3: What is the most common cause of intermittent failures?

A: Cracked solder joints, particularly those under large components subjected to thermal cycling or mechanical stress, are the leading cause of frustrating intermittent faults. The crack makes and breaks contact with changes in temperature or vibration.

Q4: How can I determine the root cause of a damaged board?

A: Follow a systematic process: 1) Visual inspection under magnification for burns, cracks, or corrosion, 2) Electrical testing to locate shorts or opens, 3) Thermal imaging to find hotspots, and 4) Cross-sectional analysis (microsectioning) for internal defects like via cracks or voids. The failure site's location and morphology often point directly to the cause.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..