Date: 2025-11-05

Let me show you where these two-layer flexible circuit boards actually get used in the real world. They're the perfect solution when you need more capability than a simple single-layer board but don't want the cost and complexity of going multi-layer.

Consumer Electronics: Where They're Used Most

You'll find these boards in devices that need to be both compact and functional:

Foldable phones and tablets use them in the hinge area connecting the screen to the mainboard. These boards can handle being folded thousands of times while carrying multiple signals - display data, touch information, and power - all things a single-layer board would struggle with.

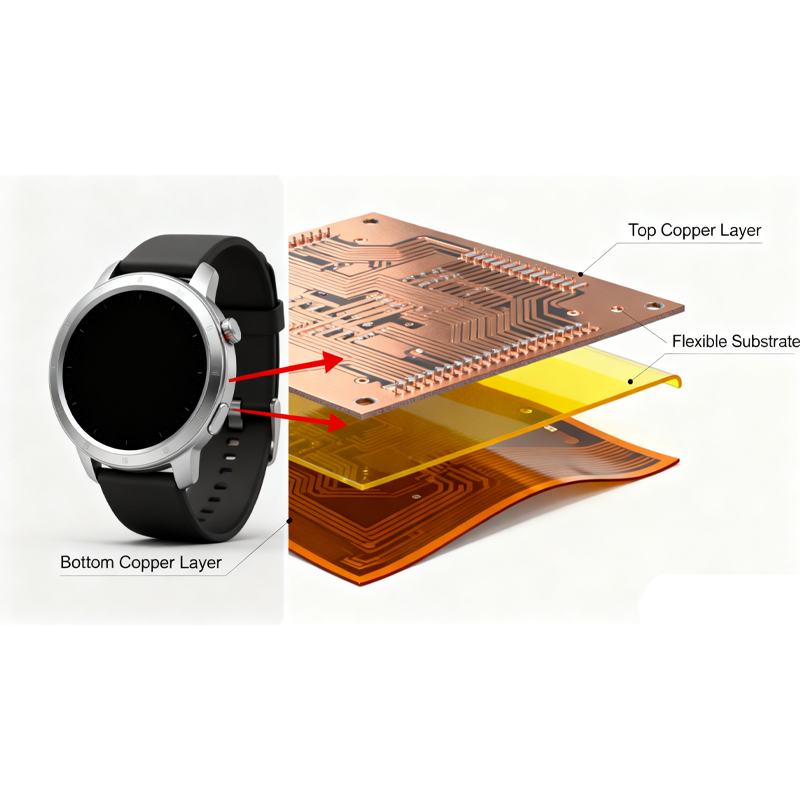

Smartwatches and fitness trackers pack these into their tiny bodies. When you've only got coin-sized space to work with, putting circuits on both sides lets you connect heart rate sensors, displays, and batteries without adding bulk. Plus, they can bend to fit the curved shape of the device.

Wireless earbuds use them both inside the earbuds and in the charging case. They bend to fit the odd-shaped spaces while handling audio signals and power management on different layers.

Small home appliances like cordless vacuums and mini blenders use them to connect controls to motors in tight, curved handles where regular boards won't fit.

Automotive Applications: Where Reliability Matters

Cars are tough environments with vibration and temperature swings, but these boards handle them well:

Sensor connections for backup sensors and tire pressure monitors use these boards because they can bend to fit odd spaces like bumpers and wheel wells while keeping signals clean.

Camera systems around the vehicle use them to route both video signals and power through tight spaces without needing separate cables.

Interior controls in seats and steering wheels benefit from boards that can curve with the design while handling multiple button inputs.

Medical Devices: Where Small Size Meets Precision

Medical equipment needs to be both compact and reliable:

Portable monitors for blood sugar and oxygen levels use these boards to connect sensors, screens, and power in palm-sized devices.

Medical imaging equipment often uses them for external connections that need to bend during procedures while maintaining signal quality.

Wearable monitors for heart tracking use them because they're comfortable against skin and can handle both data and power in a thin, flexible package.

Industrial and Smart Home Uses: Where Practicality Wins

These are the workhorse applications where cost and performance need to balance:

Factory sensors and small actuators use them in tight spaces like robot joints where they need to bend while handling both sensing and control signals.

Smart home devices from door locks to robot vacuums use them in spaces too tight for regular boards but where more than basic functionality is needed.

When Should You Choose Double-Sided Flex?

Think about these boards when your project needs:

To bend or fit in curved spaces

More connections than a single layer can handle

Good performance without multi-layer costs

They're like the perfect family car - not as basic as a bicycle, not as fancy as a sports car, but just right for most everyday needs.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..