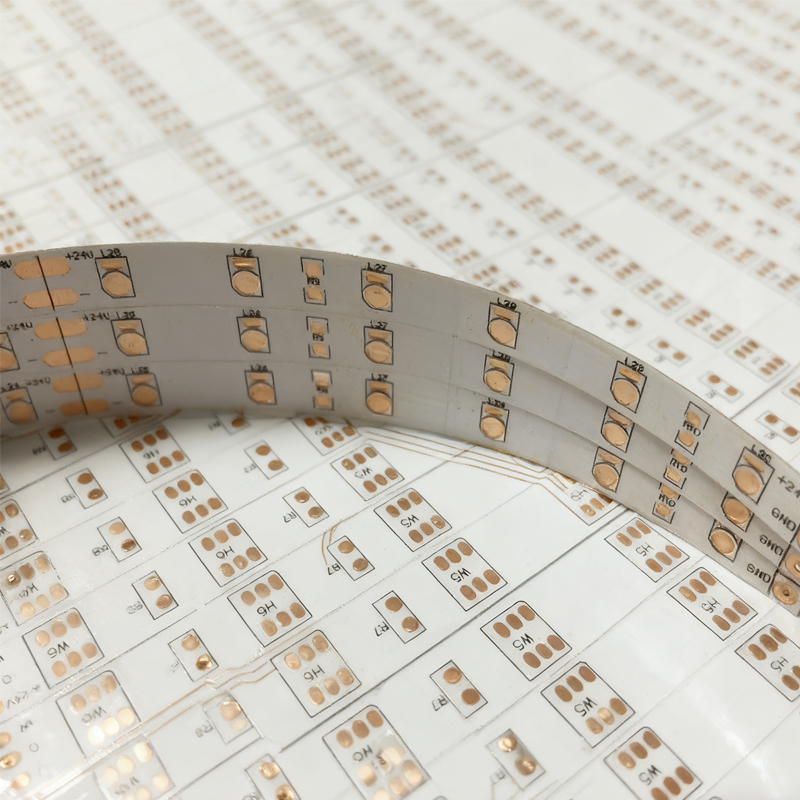

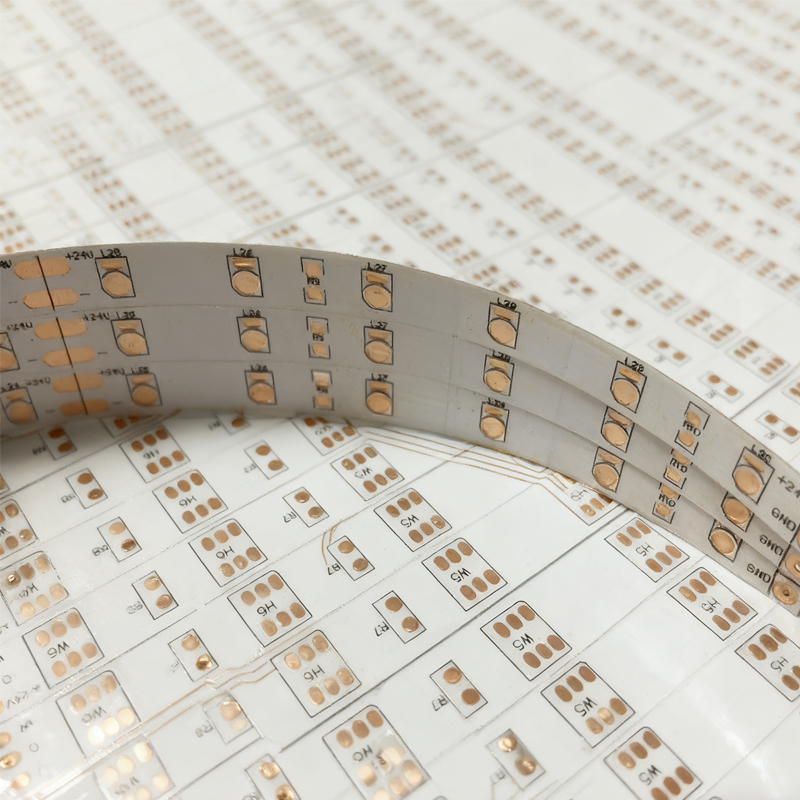

Caboer: Professional Manufacturer of LED Strip Flexible PCB Boards

Date: 2025-12-03

In the LED lighting and decoration industry, the core requirements of LED strips—flexible shaping, uniform illumination, and stable durability—rely heavily on the performance of specialized flexible PCB boards (LED Strip FPC). Focusing on the manufacturing needs of the LED sector, Caboer leverages its core FPC manufacturing technology to produce high-reliability, high-adaptability flexible circuit boards tailored for various LED strips, emerging as a preferred production partner for global LED manufacturers.

-

Adopts modified PI substrate (thickness: 12-25μm) + roll-annealed copper foil (thickness: 9-18μm) with a minimum bending radius of 0.3mm. It can be freely folded, wrapped, and attached to curved/irregular surfaces (e.g., ceiling coves, automotive contours, furniture edges), perfectly fitting the installation requirements of decorative lighting.

-

Passes one million bending cycles without wire breakage, maintaining stable performance during long-term dynamic use (e.g., foldable LED strips) and eliminating the common issue of brittle fracture in conventional PCB boards.

-

Relies on LDI laser direct imaging technology to achieve precise wiring with line width/spacing of 10μm/10μm. This guarantees uniform spacing (minimum 5mm) for LED chips (2835/5050/5730 and other models) and consistent current transmission, eliminating dark spots or uneven brightness.

-

Optimizes copper foil paths and thickness to reduce line impedance (≤50mΩ/m) and voltage drop, supporting uniform brightness for long LED strips (up to 5 meters without dimming at the ends).

-

Selects high thermal conductivity PI substrate (thermal conductivity ≥0.8W/(m·K)) paired with thin cover film, improving heat dissipation efficiency and reducing LED operating temperature by 15-20℃ (tested data).

-

Offers adhesive-free FPC structure for high-end products, reducing thermal resistance layers and enhancing heat dissipation by an additional 30%. This prevents LED degradation due to overheating, extending the strip’s lifespan to over 50,000 hours.

-

End-to-End Quality Control System: 100% inspection of core raw materials (DuPont PI substrate, high-purity copper foil) upon arrival; first-article inspection + regular patrols at key production processes (lithography, etching, lamination); 100% electrical testing (continuity/insulation/withstand voltage) + AOI visual inspection for finished products. Product qualification rate ≥99.8%.

-

Comprehensive Compliance Certifications: RoHS, REACH environmental standards compliant; UL flame retardant certification (94V-0); operating temperature range -40℃~125℃; humidity resistance (85℃/85%RH for 1000h), suitable for indoor and outdoor environments.

-

Indoor Decorative Lighting: Ceiling cove lighting, furniture-embedded strips, mall window decorations, KTV/hotel ambient lighting;

-

Automotive Electronics: Automotive interior ambient lights (door panels, dashboards, sunroofs), welcome lights, trunk lighting strips;

-

Commercial Lighting: Billboard backlighting, shelf lighting, display cabinet strips, office/hospital corridor lighting;

-

Outdoor Landscaping: Building contour lighting, bridge decorative strips, garden lighting, holiday decorative lighting;

-

Industrial & Special Scenarios: Equipment indicator strips, explosion-proof LED strips, low-temperature environment (e.g., cold storage) lighting.

-

Flexible Production Lines: Supports continuous roll production, enabling quick switching between small-batch trial production (≤100 meters) and large-scale mass production (≥100,000 meters) to adapt to different order sizes.

-

Fast Delivery Guarantee: Small-batch trial production delivered in 3-5 days; large-scale orders delivered in 15-20 days, helping customers shorten product time-to-market.

-

Value-Added Production Services: Offers integrated supporting services such as LED chip soldering, waterproof treatment, and terminal pre-installation, reducing customers’ subsequent assembly processes and production costs.

-

Professional Technical Support: Provides 24/7 technical response for issues related to soldering compatibility, dimension adjustments, and performance optimization, ensuring smooth production.

-

Flexible Adaptability: Breaks rigid limitations to meet diverse installation needs;

-

Stable Reliability: Precision manufacturing + heat dissipation optimization ensure uniform illumination and long lifespan;

-

Customization Flexibility: Full-dimensional production parameter customization for different LED models and scenarios;

-

Hassle-Free Cooperation: Focuses on production, offering efficient mass production, stable delivery, and supporting services to lower cooperation barriers.

If you are seeking a "high-flexibility, high-reliability, customized" production partner for LED strip-specific PCB boards, contact Caboer today for free sample testing and mass production quotes!