Date: 2026-02-04

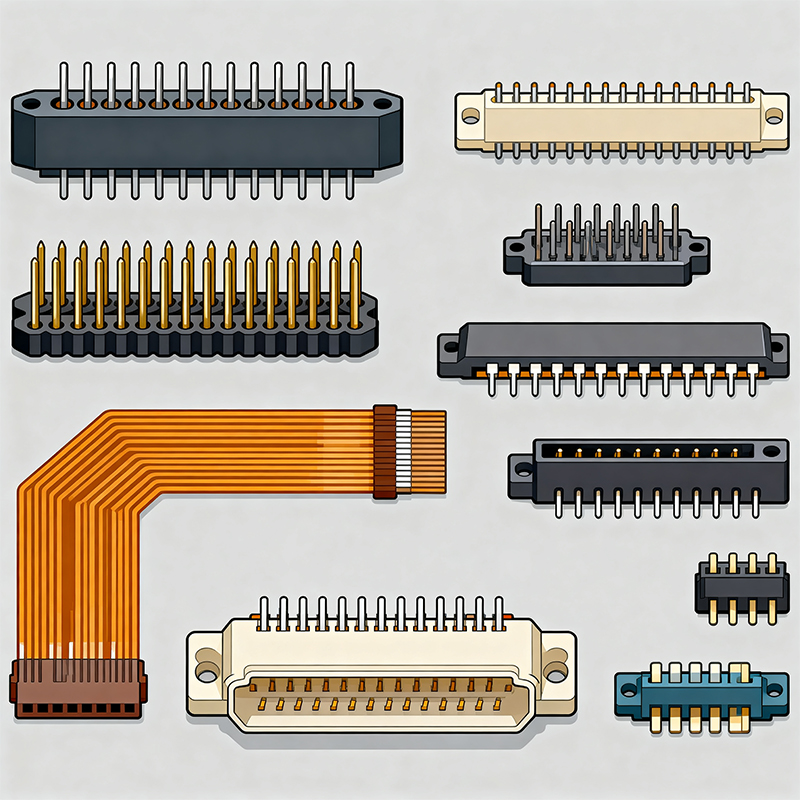

If the printed circuit board is the “nervous system” of an electronic device, then PCB connectors are the vital “joints” and “sockets” within that system. They are components responsible for establishing reliable, detachable electrical connections between the board and the outside world—be it power supplies, signal cables, another board, or peripheral devices. Understanding different connector types is essential for designing electronics that are manufacturable, testable, and maintainable.

In simple terms, connectors address two core needs: electrical conduction and mechanical attachment. A quality connector must ensure stable signal or power transmission throughout the device’s lifetime while withstanding a certain number of mating cycles, vibration, and environmental factors.

The world of connectors is vast. We can understand and select them by looking at a few key dimensions.

This is the most basic classification, determining how the connector mates with the PCB.

Through-Hole Connectors: These have pins that are inserted into corresponding drilled holes in the PCB and soldered on the opposite side (typically via wave soldering). Their advantage is extremely high mechanical strength, creating a very robust connection. They are often used where significant stress or repeated mating is expected, such as power inputs, sturdy board-to-board links, or industrial control interfaces.

Surface-Mount Connectors: The solder tails of these connectors sit directly on the PCB surface and are attached via reflow soldering. Their greatest advantage is space savings and compatibility with high-automation assembly, making them the preferred choice for modern, high-density, miniaturized devices like smartphones and tablets. However, their sheer strength perpendicular to the board is usually less than through-hole types.

This is the classification engineers encounter most in daily design work.

Board-to-Board Connectors

Used to directly connect two parallel PCBs, acting as the “building blocks” for stacking internal components. They are typically used in mated pairs (male/female) and come in various stacking heights to achieve specific inter-board distances. Their pin arrangements can be single or double-row, with common pitches like 1.27mm, 1.0mm, 0.8mm, or even finer.

Wire-to-Board Connectors

This is the broadest category, used to attach cables (wires) to a PCB. It includes many sub-types:

Pin Headers and Sockets: The simplest form, consisting of one or more rows of straight pins and their corresponding receptacles, commonly found on development boards and internal module interconnects.

Boxed/Receptacle Connectors: Feature a plastic housing for better guidance and protection. Common standard I/O ports like USB, HDMI, and RJ45 Ethernet jacks (the board-side part) fall into this category.

Screw/Cage Clamp Connectors: Such as terminal blocks, allow wires to be inserted and clamped directly without pre-soldering. They are often used for power, lighting, and industrial control for easy installation and maintenance.

Board-to-FPC/FFC Connectors

This often refers to connectors that are SMT or THT soldered to the board, but the plug mates with a terminated flexible cable. For example, many FPC/FFC connectors use a locking lever to clamp a flexible flat cable onto the contacts, widely used for connecting displays, camera modules, etc.

Input/Output Connectors

These are the device’s external interfaces, the parts users interact with directly. They typically integrate standardized mechanical forms and electrical definitions and emphasize durability and ergonomics. Beyond the common USB and HDMI ports, this category includes audio jacks, DC power jacks, SD card sockets, and more.

With a vast array of options, how do you choose correctly? Here’s a quick checklist:

Electrical Parameters:

Current & Voltage Rating: How much current and voltage can the connector safely carry? Requirements for power and signal connectors are worlds apart.

Pin Count & Pitch: How many circuits are needed? What is the center-to-center pin distance? This dictates the connector’s physical size.

Signal Integrity: For high-speed signals (e.g., USB 3.0, HDMI, PCIe), the connector’s impedance matching, crosstalk, and shielding performance are critical.

Mechanical Parameters:

Mating Cycles: How many connect/disconnect cycles are expected over the product’s life?

Locking Mechanism: Is a latch, screw, or lock required to prevent accidental disconnection?

Mated Height & Footprint: How much board space does it occupy? How tall is it once installed?

Gender: Do you need a plug (male), receptacle (female), or both?

Environmental & Reliability:

Operating Temperature Range: What environment will the product operate in?

Ingression Protection: Is protection against dust and water (e.g., an IP rating) needed?

Corrosion Resistance: Will it be exposed to moisture or corrosive atmospheres?

Manufacturing & Cost:

Soldering Type: Choose SMT or THT? This impacts assembly process and cost.

Supplier & Availability: Is it from a mainstream supplier? What are the lead times and long-term supply stability?

Though small, connectors are a critical, often underestimated part of electronics design. From power terminals ensuring safe high-current delivery to shielded interfaces carrying high-speed data streams, and down to miniature board-to-board connectors enabling sleek designs, each type exists to serve a specific need. Understanding and correctly selecting connectors is a vital step in ensuring your electronic device is stable, reliable, easy to produce, and meets end-user requirements. Considering connector selection early in the design phase can effectively avoid later redesigns, production issues, and product failures.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..