Date: 2025-12-15

Electron Devices and Circuits — you likely encounter this term in textbooks or engineering documents. It might sound fundamental, even academic. But let us tell you, this very foundation constitutes the physical soul of every smart device, industrial controller, or advanced system you are developing.

For manufacturers seeking to transform innovative designs into reliable, mass-producible products, understanding the path from the theory of "devices and circuits" to the reality of a "Printed Circuit Board Assembly" is key to success. This is where a partner like Kaboer adds definitive value: we specialize in translating your electronic design blueprints into high-quality physical products with precision and efficiency.

Simply put, this describes the two fundamental layers of an electronic system:

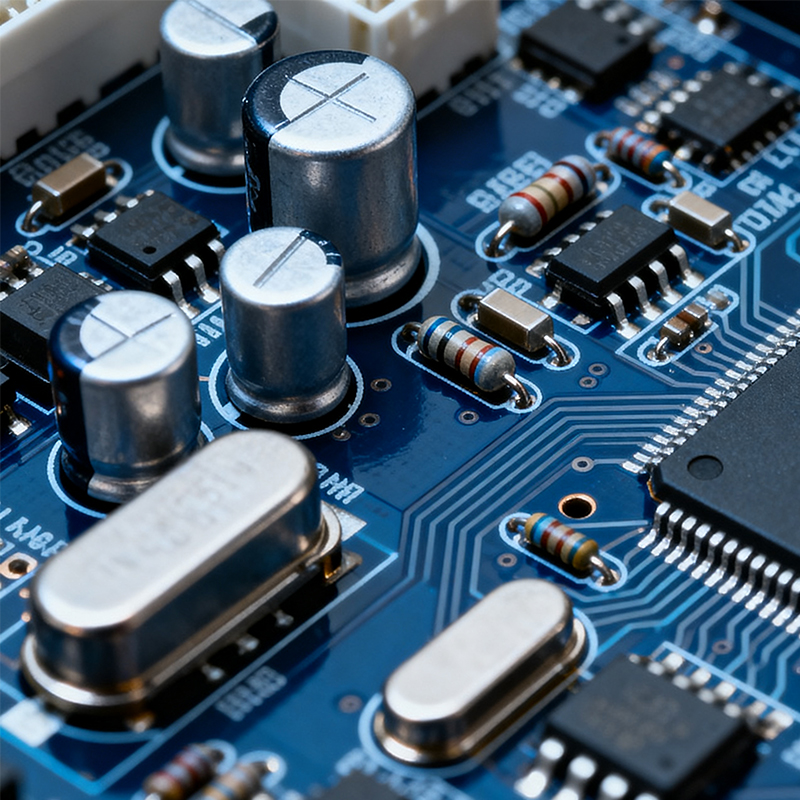

Electron Devices: These are the basic "building blocks". Each has a unique function:

Passive Devices: Like Resistors (limit current), Capacitors (store charge), Inductors (store magnetic energy). They are the foundation.

Active Devices: Like Transistors (amplify or switch signals), Integrated Circuits (miniaturized circuits on a chip, e.g., microprocessors, memory). They are the core of intelligence and control.

Interconnect & Interface Devices: Connectors, relays, sensors. They enable internal connections and communication with the outside world.

Circuits: This is the network or pathway that interconnects various electronic devices according to specific logic and topology. A circuit defines how current flows and information is processed to achieve a function—be it amplifying a signal, filtering a frequency, performing a calculation, or controlling a motor.

The Relationship: If an electronic product is a city, then electron devices are the buildings (houses, factories, power plants), and circuits are the roads, power grids, and communication networks connecting them. Great design requires not only selecting the right "buildings" but also planning an efficient, reliable "city layout."

Understanding devices and circuits is the first step. Translating that understanding from a schematic or PCB layout into thousands of consistent, reliable physical units is a different expertise—this is PCBA Manufacturing.

This leap faces real-world challenges:

Component Sourcing & Supply Chain: Navigating global volatility to secure genuine, sufficient components on time.

Design-for-Manufacturability Transition: Is the theoretical design compatible with high-precision assembly? Do pad designs ensure reliable soldering?

Precision Assembly: Especially with micro-components like 01005 or high-density BGAs, requiring micron-level placement accuracy and strict thermal process control.

Testing & Quality Assurance: How to verify every produced board performs to its designed function, not just "looks soldered"?

Based in Shenzhen, China — the heart of global electronics manufacturing and supply chains — Kaboer, as a professional PCBA manufacturer with our own factory, deeply understands the gap between the theory of "electron devices and circuits" and manufacturing practice. We are dedicated to bridging it.

Our role is to act as a professional extension of your design team, responsible for transforming your "electron devices and circuits" design into a high-quality end product.

End-to-End Support from Theory to Practice:

Manufacturability Analysis: Before production, our engineering team reviews your design, suggesting optimizations from an assembly perspective to prevent issues and improve yield.

Supply Chain Solutions: Leveraging our location in Shenzhen and mature procurement network, we offer reliable component sourcing and kitting to navigate supply chain challenges.

Precision Manufacturing Capability: Our own factory is equipped with high-speed SMT lines, precision optical inspection equipment, and functional testing stations, handling assemblies from simple to highly complex.

Focus on Reliability and Consistency:

We understand that for manufacturers, performance consistency and long-term reliability are as crucial as functionality. Through strict process control, comprehensive testing (AOI, SPI, Functional Test), and full traceability, we ensure every delivered PCBA meets high standards.

Clear and Efficient Collaboration:

We offer flexible services from rapid prototyping to medium-high volume production. Transparent communication and project management keep you informed of production status, even from overseas.

"Electron Devices and Circuits" is where the idea starts; a manufacturable, reliable PCBA is where the product succeeds. In today's competitive market, choosing a partner with technical understanding, manufacturing expertise, and supply chain resilience is crucial.

If you are looking for a Chinese manufacturing partner who can accurately understand your design intent and efficiently translate it into a reliable physical product, Kaboer is ready. Let's work together to turn your excellent circuit design into a market-leading product.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..