Date: 2026-01-12

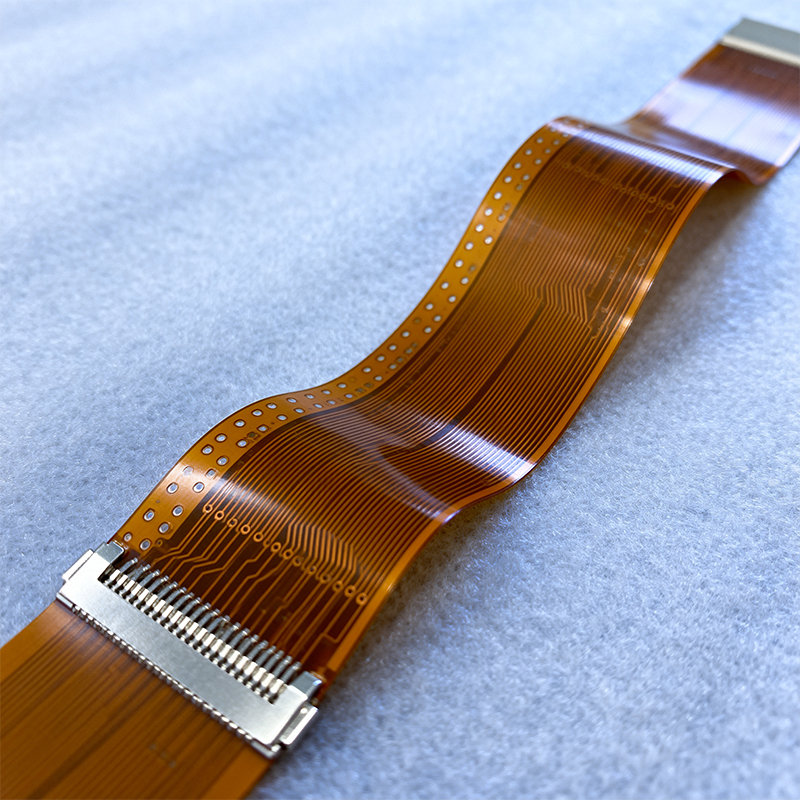

Flexible circuits are more than just bendable boards—they're an engineering solution with specific electrical and mechanical properties. When you're looking into flexpcb options, you're likely weighing technical feasibility against cost and reliability. Understanding the material and performance characteristics can make the difference between a robust design and one that fails in the field.

The core of a flex circuit's performance lies in its material stack-up. Most use a polyimide (PI) film base, like Kapton, known for its:

High-Temperature Endurance: With a glass transition temperature (Tg) typically exceeding 250°C, it withstands multiple lead-free solder reflow cycles without degradation.

Excellent Dimensional Stability: Low coefficient of thermal expansion (CTE) minimizes stress on copper traces during thermal cycling.

High Dielectric Strength: Provides reliable electrical insulation even in thin layers (common variants: 0.5mil, 1mil, 2mil thickness).

The conductive layer is typically rolled annealed (RA) copper, chosen for its better flex endurance over electro-deposited (ED) copper. Adhesives or adhesiveless (cast) construction methods further define performance, with adhesiveless offering superior thermal resistance and thinner profiles.

When designing with flexpcb, several technical parameters directly impact manufacturability and longevity:

Bend Radius: This is critical. The static (one-time install) bend radius should be at least 6x the total circuit thickness. For dynamic flexing (repeated bending), it increases to 10x-20x. Violating this leads to copper cracking.

Trace Width/Spacing: Standard capabilities for flex are around 3/3 mil (0.075mm), but advanced processes can achieve 2/2 mil. Wider traces are recommended in bend areas to improve reliability.

Stiffener Integration: FR-4 or polyimide stiffeners are often laminated to areas with components or connectors to provide mechanical support for SMT assembly. The choice affects both the assembly process and the final flex point.

Surface Finishes: ENIG (Electroless Nickel Immersion Gold) is common for its flat surface and solderability. Immersion Silver or OSP are options but offer less protection for repeated flexing.

A technically-informed design proactively addresses these known issues:

Conductor Fatigue: Cracks in copper traces after repeated bending. Mitigation: Use curved traces instead of right-angle turns in flex areas. Orient traces perpendicular to the bend axis where possible. Employ hatched copper pours.

Coverlay Delamination: The protective polyimide cover layer peeling off. Mitigation: Ensure proper adhesive flow during lamination by specifying adequate coverlay access windows. Design rounded corners for coverlay.

Solder Joint Stress: Rigid components cracking solder joints on a dynamic flex. Mitigation: Use stiffeners under components, apply epoxy spot bonding (strain relief), and avoid placing large components near bend zones.

Translating a flex design into a reliable product requires specialized process controls:

Lamination Pressures & Temperatures: Must be precisely controlled to bond layers without squeezing adhesive into vias or causing dimensional shift.

Etching Compensation: Thin copper requires different etch compensation factors than rigid boards to achieve the target trace width.

Handling & Fixturing: Throughout fabrication and assembly, flexible material needs specialized frames and carriers to prevent stretching or tearing in automated equipment.

At our Shenzhen factory, we bridge the gap between flex PCB design and high-yield manufacturing. Our technical approach includes:

DFM Review with a Focus on Reliability: We don't just check for minimum spacing. We analyze bend areas using your mechanical models, recommend trace routing patterns, and advise on stiffener placement to optimize for both assembly and in-life performance.

Process-Controlled Assembly: We use dedicated flex carriers and pallets throughout our SMT lines. Our reflow profiles are carefully tuned for the thermal mass of flex boards to prevent warping. For complex rigid-flex assemblies, we employ sequential lamination and selective press-fit techniques.

Validation Testing: Beyond standard electrical testing, we can perform bend cycle testing on prototypes (to IPC-6013 standards) and offer micro-section analysis to audit via and plating integrity, providing data to support your design decisions.

Choosing to implement a flexpcb is a technical decision with long-term reliability implications. Success depends on:

Designing to the material's capabilities, not against them.

Selecting a manufacturer with proven flex fabrication and assembly process controls.

Validating the design through proper mechanical prototyping.

When your product demands functionality that only flex circuits can provide, partnering with a technically-competent manufacturer like Kaboer ensures that the inherent advantages of the technology—lightweight, space-saving, and dynamic—are fully realized without compromising on quality or durability.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..