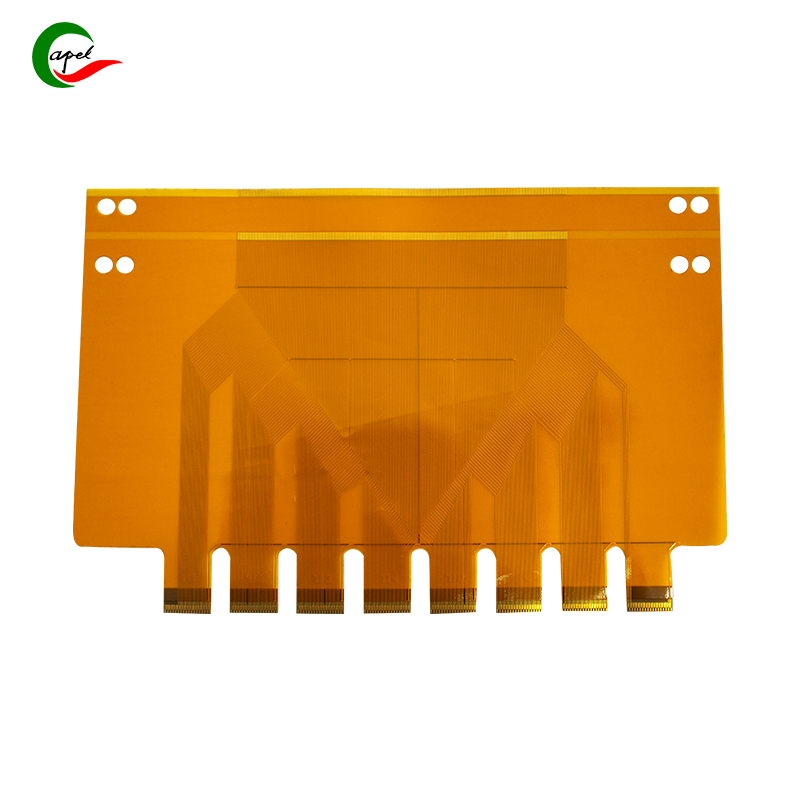

Flexible Printed Circuits (FPCs) power bendable devices—foldable phones, wearables, and automotive sensors. Their copper traces need surface finishes to resist oxidation and enable reliable soldering. Unlike rigid PCBs, FPCs bend thousands of times, so finishes must balance flexibility, protection, and cost.

Three options dominate: ENIG (Electroless Nickel Immersion Gold), Tin Plating, and OSP (Organic Solderability Preservative). Below’s a concise guide to their traits, uses, and how to choose.

Rigid PCBs only need finishes for oxidation resistance. FPCs need more:

-

Flexibility: Finishes must bend without cracking (e.g., a smartwatch FPC moves with your wrist).

-

Durability: Resist sweat, oil, or vibration (e.g., automotive sensors).

-

Solder reliability: Ensure joints hold during bending (e.g., foldable phone screens).

A bad choice? A wearable might fail in months, or a sensor could lose signal.

ENIG has two layers: nickel (2–5 μm) + thin gold (0.05–0.1 μm). Nickel blocks oxidation; gold boosts corrosion resistance.

-

Flexibility: Good (10,000+ bends).

-

Corrosion resistance: Excellent (500+ hours salt spray).

-

Solder life: 6+ months (no rework).

-

Cost: High (2–3x vs. tin/OSP).

-

Foldable phones: Samsung Z Fold uses ENIG—resists sweat, bends 200,000+ times.

-

Medical wearables: Glucose monitors rely on its moisture resistance.

-

Automotive sensors: Handles engine heat (150°C) and oil.

Rare nickel whiskers (fixed with phosphorus in nickel).

Tin (5–15 μm) is cheap and ductile—electroplated directly on copper.

-

Flexibility: Excellent (50,000+ bends).

-

Cost: Low (50–70% cheaper than ENIG).

-

Solderability: Great (no extra flux).

-

Corrosion: Moderate (tarnishes after 3 months).

-

Budget wearables: Xiaomi Mi Band uses tin—fits $50 price, bends with wrists.

-

Cables: USB-C FPCs rely on its flexibility and low cost.

-

Toys: Remote cars use tin—cheap for high volume.

Tin whiskers (fixed with tin-copper alloy).

OSP is a thin organic film (0.1–0.5 μm) on copper—blocks oxidation temporarily.

-

Thickness: Ultra-thin (good for tiny devices).

-

Cost: Low (similar to tin).

-

Eco-friendly: No heavy metals.

-

Durability: Poor (wears off in moisture).

-

Earbuds: Apple AirPods uses OSP—fits tiny cases.

-

Disposable medical strips: Cheap, easy to recycle.

-

Laptop webcams: Thin, no bulk.

Solder life: 1–3 months; no rework.

-

Environment: Moist/sweaty? ENIG. Rough use? Tin. Tiny spaces? OSP.

-

Production: High-volume? Tin/OSP. Long storage? ENIG.

-

Cost: Budget? Tin/OSP. Premium? ENIG.

-

OSP for fitness trackers: Moisture ruins it—use tin.

-

ENIG for toys: Wastes money—tin works.

ENIG = premium durability; Tin = budget flexibility; OSP = thin eco-friendliness. Match the finish to your device’s needs—this ensures reliability without overspending.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.