Date: 2025-10-29

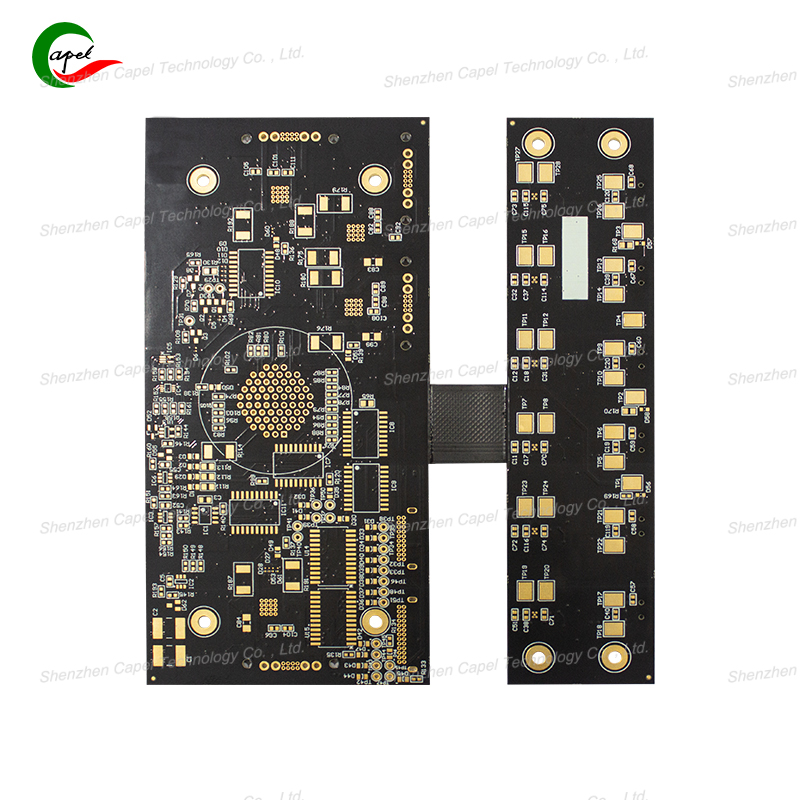

Let's talk about those super-small connection points on rigid-flex boards - you know, the ones that can make or break your entire design. Getting these micro-pads perfect is crucial, but honestly, most suppliers struggle with the precision needed. Here's how we're handling it differently.

We use laser cutting that's basically like performing world's tiniest surgery on your boards. Our fiber lasers can hit accuracy within 0.01mm - that's about one-tenth the width of a human hair. Why does this matter? Well, when those tiny pads are cut perfectly, your components actually fit right the first time. No more fighting with misaligned parts during assembly.

Here's what working with us looks like:

You get straight answers from our engineers about what's possible and what's not. No technical mumbo-jumbo - just clear facts about tolerances, timelines, and trade-offs. If you need a specific pad size or spacing, we'll tell you exactly how we can make it happen.

We actually listen to your requirements. If your design needs special adjustments for those micro-connections, we'll work with you to tweak our laser process until it matches what you're looking for.

You'll see exactly how your boards are coming along. We'll send you photos and updates showing the laser cutting results and quality checks. No surprises when the boards arrive.

The practical benefits are pretty straightforward:

Your production yield goes up because components actually fit properly. We've seen customers reduce their assembly headaches significantly after switching to our laser-cut pads.

Everything works more reliably - better connections, cleaner signals, and fewer field failures. Those perfectly cut pads mean solid solder joints and consistent performance.

You save money by avoiding rework, scrap, and production delays. Getting it right the first time is always cheaper than fixing problems later.

What makes our approach special:

Our laser technology leaves clean edges without damaging the board materials. The flexible sections stay flexible, the rigid parts stay strong, and everything just works together.

Since we make everything in our own factory, we can maintain tight quality control from start to finish. Every batch meets the same high standards.

We've handled all kinds of micro-pad designs for everything from medical implants to automotive sensors. If you can design it, we can probably laser-cut it.

The bottom line? If you're tired of fighting with tiny connections that never seem quite right, our laser cutting process might be your solution. We're helping manufacturers create better products by mastering the small details that make a big difference. Your boards work better, your production runs smoother, and your customers stay happier. And honestly, that's what really matters.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..