Date: 2025-10-28

Let's cut to the chase - regular circuit boards can't handle radiation. They break down, get brittle, and stop working. But we've cracked the code on making boards that actually survive in tough environments like space, nuclear facilities, and medical equipment.

So how does this actually work?

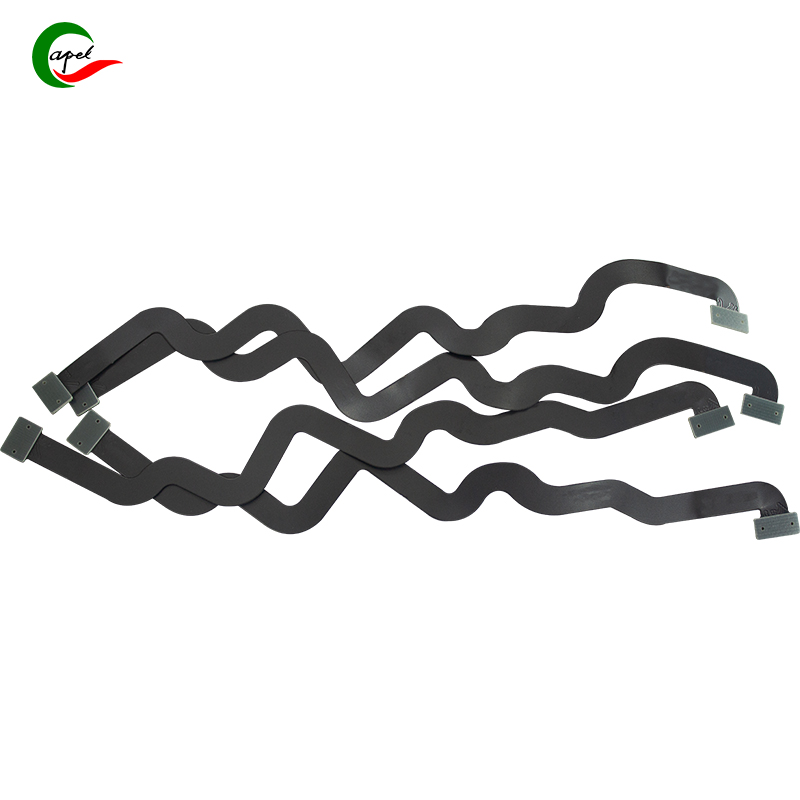

We use space-grade materials that don't fall apart when radiation hits them. Think of it like this - we're building the circuit board equivalent of radiation-proof armor, but it still bends and flexes exactly where you need it to.

The secret sauce is in the material science. We use special polymer blends - mostly enhanced polyimides and custom epoxy systems - that maintain their molecular structure even when bombarded with radiation. Your signals stay clean, your connections stay solid, and the board doesn't turn into a brittle mess after six months.

Why this matters for your projects:

If you're putting electronics anywhere near radiation, you know the pain points. Standard boards might last a year if you're lucky. Ours are built to keep going for years without failing. We're talking about boards that handle the equivalent of multiple chest X-rays every day and just keep working.

The best part? You're not sacrificing anything. The boards still bend, still fit in tight spaces, and still do everything you need flexible circuits to do. We've just made them radiation-proof while we were at it.

Where this really makes a difference:

Space equipment that can't have maintenance calls

Nuclear plant monitoring systems

Medical devices that get sterilized regularly

Anywhere failure isn't an option

We've seen these boards outlast standard versions by 3x in high-radiation environments. That means less downtime, fewer replacement costs, and way more reliable equipment.

It's not magic - it's just better materials and smarter manufacturing. We're building boards that can take the punishment that would destroy regular circuits in months.

Bottom line: If you're tired of replacing radiation-damaged circuits, this is your solution. We're making boards that survive where others can't, and that means your equipment stays online longer and works better. Plus, you'll look pretty smart when your gear outlasts everyone else's.

The technology's here, it's proven, and it's working right now in some of the toughest environments on Earth - and beyond.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..