Date: 2025-11-08

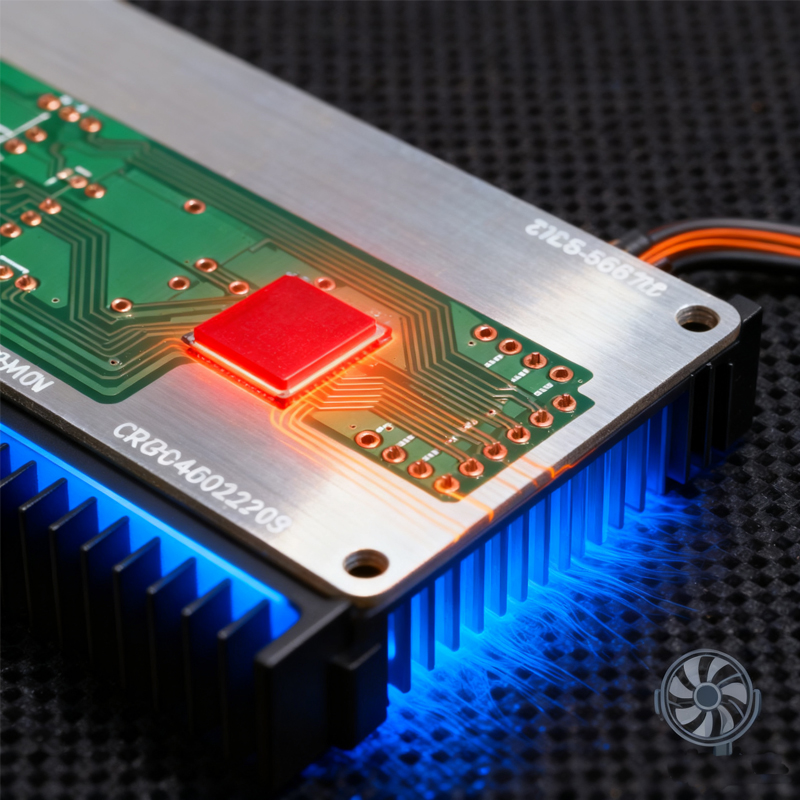

Look, when your electronics get hot, they start failing. It's that simple. Aluminum circuit boards exist for one job: to solve that heat problem.

While regular boards are great for cheap, complex circuits, they're terrible at cooling. Aluminum boards are the specialists you call when heat is your number one enemy. Here’s why they actually work.

1. They Suck Heat Away From Sensitive Parts

Imagine a high-power LED or transistor. It gets crazy hot, right? A normal board just lets that heat sit there, cooking the component. An aluminum board acts differently.

The special layer underneath the copper pulls heat down into the aluminum base like a magnet.

This can drop your component's operating temperature by 30-60% compared to a standard board.

Translation: Your parts don't burn out. Your LED doesn't slowly dim over time. Things just keep working.

2. They Stop "Hot Spots" From Forming

It's not just about moving heat down - it's about spreading it out. When you have several power components close together, one usually gets hotter than the others and fails first.

The aluminum base spreads heat evenly across the whole board.

Temperature differences between nearby components stay within just a few degrees.

This means all your components share the heat load equally. No single weak link fails and takes down your whole system.

3. They Make Your Product Last Years Longer

Heat is what kills electronics over time. It's that simple.

The rule of thumb is: for every 18°F (10°C) you lower the temperature, your component lifespan doubles.

Capacitors, solder joints - everything lasts longer when they're not constantly baking.

Using an aluminum board can literally multiply your product's lifespan by 2-5 times. That's why they're mandatory in car systems and industrial equipment that needs to run for a decade.

4. They Work in Sealed Boxes and Tight Spaces

Many modern devices are sealed shut with no fans - think car headlights, waterproof power supplies.

Regular boards would let components overheat and fail in these conditions.

With an aluminum board, you can bolt the metal base directly to the device's metal case.

The whole case becomes a giant heat sink. Heat travels: Component → Board → Case → Outside air. Problem solved.

5. What Happens When You Don't Use One

If you try to cheap out and use a regular board for a high-power application:

Your thermal protection circuits will keep shutting the device down

Components will constantly operate beyond their temperature ratings

You'll see solder joints crack and insulation materials break down over time

Eventually, something will fail completely - possibly in a dangerous way

The Real Bottom Line

Choosing an aluminum board isn't about specs on paper. It's about building products that don't fail when they get hot. If your device generates significant heat, this isn't an option - it's insurance against thermal failure.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..