Imagine a sensor mounted on an offshore oil rig, enduring salt spray, 100°C heat, and constant vibration. Or a medical device taped to a patient’s skin, exposed to sweat, moisture, and daily movement. In these harsh conditions, traditional rigid PCBs often fail—cracks form, wires fray, and components short-circuit. But Flexible Printed Circuits (FPCs) are changing the game. Their unique design and materials let them survive (and thrive) where rigid boards crumble. Here’s how FPCs enhance durability in the toughest environments.

Harsh environments are often wet or chemically aggressive—think factory floors with cleaning chemicals, marine equipment in saltwater, or wearable devices in sweat. Rigid PCBs, with their porous FR-4 substrate and exposed connectors, absorb moisture and chemicals easily, leading to corrosion of copper traces.

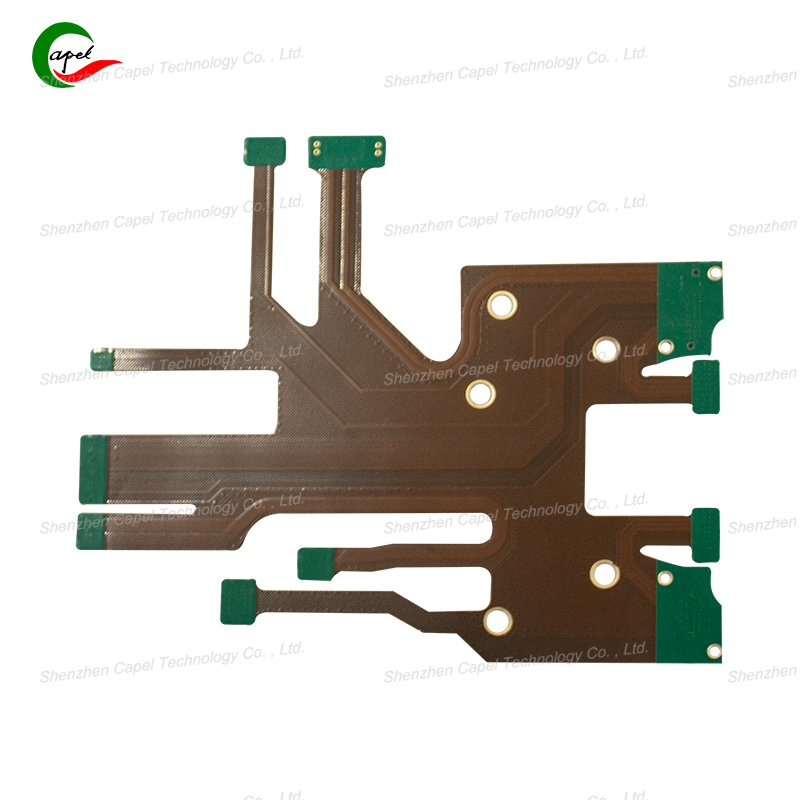

FPCs solve this with protective materials and sealed designs:

- Polyimide (PI) base film: The core of FPCs is PI, a material that repels water (moisture absorption <0.5%) and resists oils, acids, and saltwater. Unlike FR-4, PI doesn’t swell or degrade when exposed to liquids.

- Cover layers and conformal coatings: FPCs are topped with thin, flexible cover films (also made of PI or PTFE) that seal copper traces. For extra protection, manufacturers add conformal coatings (silicone or urethane) that act as a “waterproof jacket” for the circuit.

- No external connectors: FPCs integrate components and wiring into one piece, eliminating the gaps where moisture seeps into rigid PCBs.

Real example: A marine sensor using an FPC lasted 5 years in saltwater, while a rigid PCB version failed after 8 months—corrosion had eaten through the rigid board’s traces, but the FPC’s PI film and conformal coating kept it intact.

Many harsh environments (automotive engines, industrial machinery, drones) subject electronics to constant vibration or physical impact. Rigid PCBs are brittle—their soldered joints crack, and traces break when shaken or hit.

FPCs handle stress like a gymnast—flexing instead of breaking:

- Flexible traces: FPC copper traces are thin (0.01–0.05mm) and bonded to PI film, letting them stretch and bend without cracking. A rigid PCB trace might snap after 100 vibrations, but an FPC trace can survive 10,000+ cycles.

- No loose wires: Rigid PCBs rely on wires to connect components—wires fray or disconnect under vibration. FPCs have no external wires; all connections are part of the flexible board.

- Shock absorption: The PI film in FPCs acts as a shock absorber. When a drone crashes, the FPC bends with the impact, protecting components like cameras or GPS modules—something a rigid PCB can’t do.

Real example: An automotive engine sensor with an FPC had a 98% survival rate after 100,000 km of driving (exposed to engine vibration). A rigid PCB sensor had a 65% survival rate—most failed due to cracked solder joints.

From desert heat (50°C+) to arctic cold (-40°C), extreme temperatures destroy rigid PCBs. FR-4 softens at high temps (Tg=130–170°C), causing traces to shift, and becomes brittle in the cold, leading to cracks.

FPCs thrive in temperature extremes:

- High-temperature resistance: PI film stays stable up to 280°C (some grades handle 350°C), so FPCs work in engine bays or industrial ovens. The adhesive bonding FPC layers also resists heat—no delamination even at 200°C.

- Low-temperature flexibility: Unlike rigid PCBs, which snap in freezing temps, FPCs remain flexible at -60°C. This makes them ideal for outdoor devices like weather stations or polar research equipment.

- Stable performance: FPC impedance (critical for signal transmission) stays consistent across temperature swings. A rigid PCB’s impedance might vary by 20% in cold weather, but an FPC’s changes by less than 5%.

Real example: A solar panel controller in the Sahara Desert uses FPCs to connect sensors. It operates reliably at 60°C, while a rigid PCB controller failed after 3 months—its FR-4 substrate had softened, shorting the circuit.

Dusty environments (construction sites, factories, deserts) clog rigid PCBs’ gaps and connectors, causing overheating or short circuits. Rigid PCBs have tiny crevices between layers and components where dust accumulates—hard to clean and impossible to seal fully.

FPCs minimize dust risks with their slim, seamless design:

- No gaps: FPCs are thin (0.1–0.5mm) and have no separate layers or connectors that trap dust. The cover film seals the entire board, so dust can’t reach the copper traces.

- Easy integration: FPCs fit into tight, sealed enclosures (like IP67-rated cases) because they’re flexible. Rigid PCBs, with their bulk, often leave small gaps around the enclosure—dust’s entry point.

Real example: A construction site tablet uses FPCs in its touchscreen. After 6 months of use (covered in concrete dust), the touchscreen still worked perfectly. A tablet with a rigid PCB touchscreen failed—dust had gotten into the connector, breaking the touch function.

Harsh-environment devices often have irregular shapes: a curved industrial pipe sensor, a wearable medical patch, or a drone’s curved body. Rigid PCBs are flat—installing them requires forcing them into shapes they can’t handle, leading to stress cracks.

FPCs mold to the device’s shape, reducing installation damage:

- Conformable design: FPCs wrap around curves, fit into tight corners, or even fold into small spaces. A sensor for a curved pipe uses an FPC that wraps around the pipe’s surface—no bending or forcing needed.

- Lightweight: FPCs weigh 50–70% less than rigid PCBs, so they don’t add extra weight that could stress the device (critical for drones or wearable gear).

Real example: A wearable ECG patch uses an FPC that conforms to the chest. The FPC’s flexibility means it stays in place during movement, and there’s no risk of the board cracking from body bending. A rigid PCB patch would peel off or crack after a day of wear.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.