The race to shrink consumer electronics—from 10mm-thin smartphones to credit card-sized fitness trackers—has pushed engineers to rethink how components fit into tight spaces. Traditional rigid PCBs, with their fixed shapes and bulky wiring, can no longer keep up. Enter Flexible Printed Circuits (FPCs): their ability to bend, fold, and conform to 3D enclosures is unlocking the "one board, multiple components" goal—where a single FPC replaces dozens of discrete wires and small PCBs, integrating sensors, chips, and connectors into a seamless, space-saving design. Here’s how FPCs are making this possible, with real-world examples and actionable design insights.

Consumer electronics are getting smaller and more powerful. A 2024 survey by IDC found that 78% of smartphone users prioritize "slim design" over screen size, while smartwatch makers are cramming ECG sensors, GPS, and wireless charging into cases just 4mm thick. This creates a paradox: more components, less space.

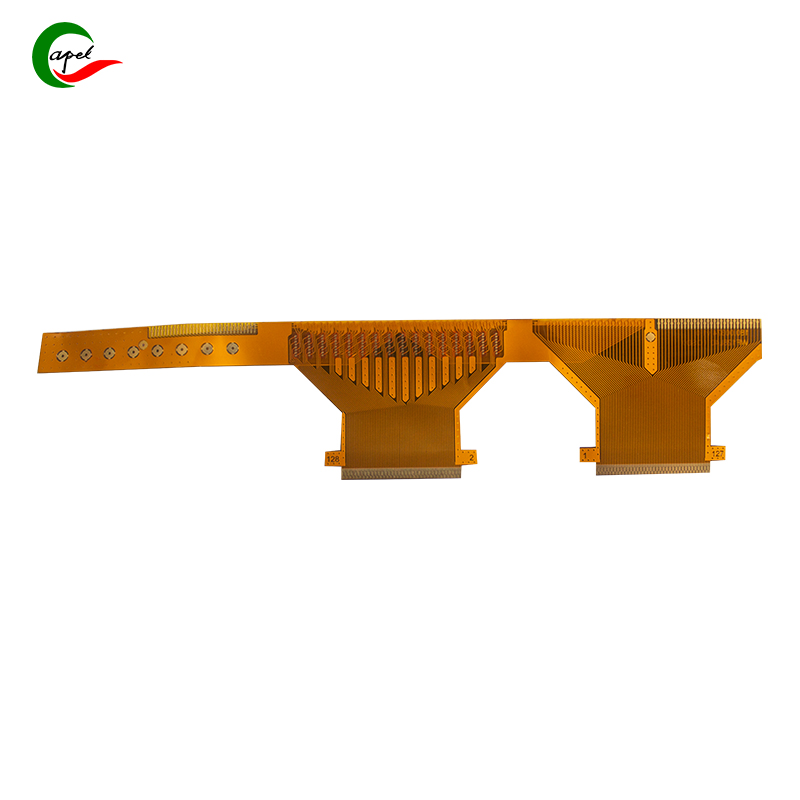

Traditional solutions—using multiple small rigid PCBs connected by wires or connectors—waste valuable real estate (connectors alone take up 15-20% of board space) and increase failure risks (wires break, connectors loosen). FPCs solve this by acting as a "flexible backbone": a single FPC can snake through the nooks of a device, connecting components that would otherwise be isolated.

Take Apple’s AirPods Pro 2: its charging case uses a single FPC to integrate a pressure sensor (for lid detection), a battery management chip, and a wireless charging coil. Before FPCs, this would require 3 separate PCBs and 5+ wires—adding 2mm to the case thickness. "FPCs cut our case volume by 12% while adding 3 new sensors," says a senior Apple hardware engineer, as quoted in a 2023 IEEE report.

Turning a single FPC into a multi-component hub isn’t just about flexibility—it requires intentional design choices to maximize density, reliability, and functionality. Below are the key strategies:

FPCs use ultra-thin copper traces (as narrow as 0.05mm, vs. 0.1mm for rigid PCBs) and thin polyimide substrates (0.025-0.1mm thick) to fit more signal paths. This allows a single FPC to carry power, data, and control signals to multiple components simultaneously.

-

Microvias for Layered Connections: Instead of bulky through-holes (which take up space and limit flexibility), FPCs use laser-drilled microvias (0.1-0.2mm diameter) to connect copper layers. Samsung’s Galaxy Z Fold5 display FPC, for example, uses 0.12mm microvias to link 6 layers of traces—enough to carry 4K display data, touch input, and sensor signals to the main chip.

-

Impedance Matching for Mixed Signals: When integrating components like 5G modems (high-frequency) and batteries (high-current), FPC designers adjust trace width and substrate thickness to maintain consistent impedance (e.g., 50Ω for data, 2Ω for power). This prevents signal interference—a common issue with discrete PCBs.

Unlike rigid PCBs, FPCs can fold into Z-shapes, wrap around curves, or even twist—letting designers place components where space allows, not just where the board fits.

-

Foldable Zones for Dynamic Components: In flip phones like Motorola Razr+, the FPC connecting the top and bottom screens has pre-defined foldable zones (reinforced with thin polyimide) that bend 200,000+ times without breaking. This single FPC integrates the display driver, front camera, and earpiece—no hinges or wires needed.

-

Conformal Design for Odd Shapes: Fitbit’s Charge 6 fitness tracker has an irregular, curved case. Its FPC is printed in a "wave" shape to follow the case’s contour, integrating a heart rate sensor, GPS chip, and OLED display. "We used to have to cut rigid PCBs into 4 pieces to fit—FPCs turned that into one part," says a Fitbit design lead in a 2024 TechCrunch interview.

To save even more space, engineers are embedding passive components (resistors, capacitors) and even small active components (ICs) directly into the FPC’s substrate—eliminating the need for surface-mount pads.

-

Embedded Passives: Japan’s J-Flex developed an FPC for Sony’s WH-1000XM5 headphones that embeds 12 resistors and 8 capacitors into the polyimide layer. This cut the FPC’s surface area by 18%, freeing up space for a larger battery.

-

Chip-on-Flex (COF) Technology: For critical components like display drivers, FPCs use COF—bonding bare IC chips directly to the FPC surface (without packaging). This reduces component size by 30% vs. traditional packaged chips. China’s BOE, a major display maker, uses COF on its smartphone OLED FPCs to integrate drivers and touch controllers into a single strip.

These consumer electronics icons show how FPCs turn "one board, multiple components" from a concept to a product:

Apple’s iPhone 15 Pro uses a single "spine" FPC that runs from the top (front camera, Face ID sensor) to the bottom (USB-C port, speaker) of the device. This FPC integrates:

-

A 3D camera sensor interface

-

USB 3.0 data lines

-

Battery charging circuits

-

Haptic feedback controller

Before this design, the iPhone used 4 separate FPCs and 2 rigid PCBs. The new spine FPC reduced internal wiring by 40% and made room for a larger 4,441mAh battery—all while keeping the phone 7.8mm thin.

Xiaomi’s Mi Band 8, a $50 fitness tracker, uses a 20mm-wide FPC to integrate:

-

A PPG heart rate sensor

-

A blood oxygen sensor

-

A 0.95-inch OLED display driver

-

A Bluetooth 5.2 module

The FPC is folded into a "U-shape" to fit around the battery, with embedded resistors to save space. "Without FPCs, we couldn’t fit a blood oxygen sensor in a device this small," says Xiaomi’s wearable product manager, as reported in a 2024 Gizmodo review.

While FPCs excel at integration, they face two key hurdles: durability and cost. Here’s how the industry solves them:

FPCs are prone to tearing at fold points or where components are soldered. To fix this:

-

Coverlays: A thin layer of polyimide or epoxy is added to high-stress zones (e.g., fold lines, connector areas). Huawei’s Watch GT 4 uses overlays on its FPC’s sensor connections, increasing bend durability by 300%.

-

Stiffeners: Small rigid patches (e.g., FR-4 or aluminum) are bonded to areas where components are mounted (e.g., IC chips). This prevents the FPC from warping under the component’s weight.

FPCs were once 2-3x more expensive than rigid PCBs, but scale has brought costs down. In 2024, major manufacturers like Japan’s Nitto Denko and China’s Shennan Circuits use roll-to-roll (R2R) production—printing FPCs on continuous rolls of polyimide—to cut per-unit costs by 40%. For high-volume devices (e.g., smartphones), FPCs now cost only 15% more than equivalent rigid PCBs.

As consumer electronics shrink further (think smart contact lenses, tiny IoT sensors), FPCs will push integration to new limits. Two emerging trends:

-

Bio-Integrated FPCs: Companies like Abbott are developing FPCs that integrate glucose sensors and wireless transmitters—thin enough to be embedded under the skin.

-

Self-Healing FPCs: Researchers at Stanford University have created FPCs with conductive polymers that repair small tears automatically, extending device lifespan.

In the age of miniaturized consumer electronics, FPCs aren’t just a "nice-to-have"—they’re the only way to fit more functionality into less space. By leveraging high-density wiring, 3D flexibility, and component embedding, FPCs turn the "one board, multiple components" goal into reality—making slimmer, more powerful devices possible. As Xiaomi’s product manager put it: "FPCs don’t just save space—they let us reimagine what a device can be."

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.