Date: 2025-10-16

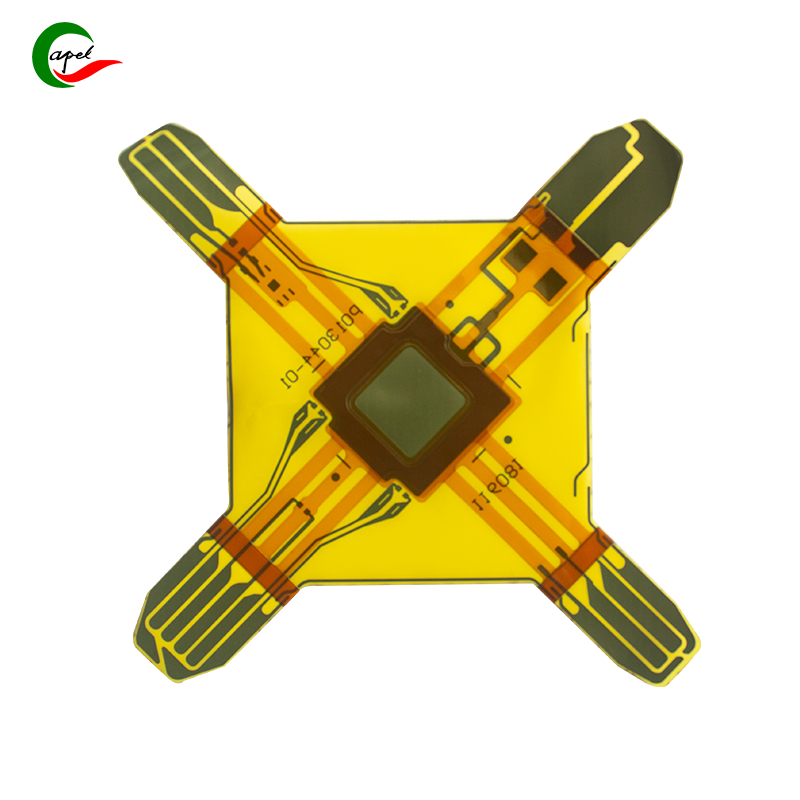

Putting chips and sensors together on flexible PCBs creates some unique engineering challenges. I've worked on several wearable medical projects where we learned these lessons through trial and error. The main issues always come down to heat management, signal integrity, and mechanical reliability.

Smart Layout Planning: More Than Just Placement

When we first started with heterogeneous integration, we made the mistake of treating flex PCBs like rigid boards. The thermal and mechanical factors turned out to be much more critical.

We now use a zoning approach that separates components by their thermal characteristics and sensitivity. High-power chips go in designated "hot zones" with adequate clearance from temperature-sensitive sensors. In one fitness tracker project, we found that keeping MEMS sensors at least 5mm from processors prevented temperature-induced drift entirely.

Space optimization requires careful balancing. While we use CSP and BGA packages to save space, we've learned to maintain minimum clearances between components. The 0.5mm rule between small sensors has proven essential - anything less risks contact during dynamic flexing.

Thermal Management: Keeping Things Cool

Heat management became our top priority after an early smartwatch design showed sensor accuracy degrading by 15% during prolonged use.

Our solution involves multiple approaches:

We embed copper heat spreaders under high-power chips, extending them to rigid sections when available

We use thin polyimide foam insulation between thermal zones

We prioritize low-power components, often choosing efficiency over raw performance

The copper spreading technique has been particularly effective. In recent designs, we've achieved temperature differentials of over 10°C between chip and sensor zones.

Signal Integrity: Fighting Interference

The combination of digital noise from chips and sensitive analog signals from sensors requires careful isolation.

We implement separated ground planes with single-point connection between analog and digital domains. This star grounding approach eliminated the noise issues we initially faced in our environmental sensor arrays.

For critical signal paths, we add shielded traces and strategic filtering. The RC filters at sensor outputs have proven crucial for cleaning up signals in our IoT sensor nodes.

Mechanical Considerations: Surviving the Bend

Flex circuits move, and your component integration must account for this. We've developed several reinforcement techniques:

Local stiffeners under heavy components prevent peeling during flex cycles. The 25-50μm PI reinforcement sheets have become standard in our designs.

We're careful with trace routing, keeping signals away from bend zones and component edges. This attention to mechanical stress points has dramatically improved reliability in our foldable display drivers.

Encapsulation selection is crucial. We've standardized on flexible silicone gels that protect components while maintaining bendability. The right encapsulant can mean the difference between a product that lasts months versus years.

Common Pitfalls We've Learned to Avoid

The most frequent mistakes we see include:

Underestimating thermal coupling between components

Compromising on grounding schemes to save space

Skipping mechanical reinforcement for cost reduction

Each of these shortcuts has caused field failures in our early designs. The thermal issue alone led to a complete redesign of our first-generation health monitor.

The Bottom Line

Successfully integrating chips and sensors on flex PCBs requires thinking about thermal, electrical, and mechanical factors together. The most reliable designs emerge when you consider all three aspects from the beginning rather than trying to fix problems later.

Through careful implementation of these principles, we've achieved measurement accuracies within 2% while maintaining the flexibility needed for modern compact devices. The approach works equally well for consumer wearables and industrial IoT sensors.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..