Date: 2026-02-06

On a smartphone motherboard, hundreds of component designators, test point labels, and unique traceability QR codes need to be marked with lines finer than a human hair—a task akin to engraving a detailed map on a grain of rice, and it's precisely what laser engraving technology accomplishes.

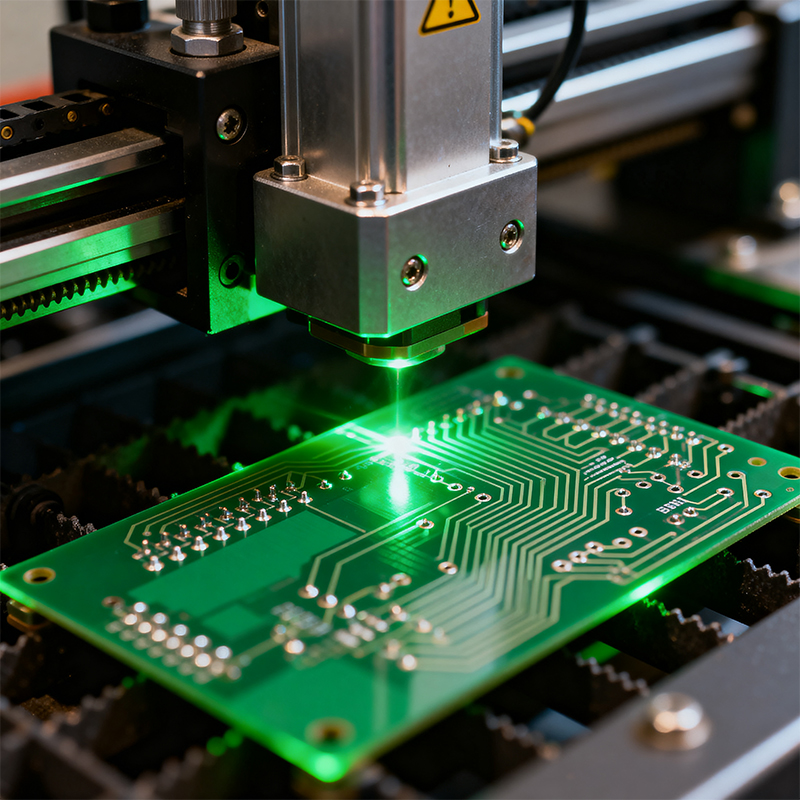

In the realm of PCB manufacturing, laser engraving is an art that transforms energy into[敏感词] precision. It uses a highly focused beam of light to "write" permanent markings onto the circuit board surface, akin to刻上 a unique "ID card" for each board.

The core value of this technology lies in its non-contact processing. Without the beam ever touching the board, precise thermal energy interaction allows for精细 operations ranging from removing surface material to altering its color.

The fundamental principle of laser engraving PCBs is a精密 "energy dialogue" between the laser and the board's surface coating. When a high-energy-density laser beam is focused on the PCB surface, it delivers a massive amount of energy to the focal point within an extremely short time (typically on the microsecond or nanosecond scale).

This causes the coating material (usually the solder mask ink or a special layer over the copper) to undergo one of three primary changes: instantaneous vaporization, a chemical change in color, or slight carbonization. By precisely controlling the laser's power, scanning speed, and pulse frequency, the depth and extent of this material transformation can be managed, resulting in clear, permanent marks.

Compared to traditional screen printing, the most significant difference with laser engraving is its digital nature. It takes instructions directly from design files (like Gerber or vector files), eliminating the need for physical stencils. This makes it exceptionally flexible, particularly suited for high-precision, low-volume, high-mix production, and scenarios requiring variable data marking (like serial numbers, QR codes).

The content laser-engraved onto a modern circuit board forms a critical informational layer for its production, assembly, and maintenance. These markings primarily fall into several functional categories.

First are component designators. This is one of the primary tasks of laser engraving, including reference designators (like R1, C5, U3) and polarity indicators (like a "+" sign or a cathode bar for diodes) for resistors, capacitors, and chips. Clear markings serve as the "map" for subsequent automated assembly and manual repair.

Next are test points, interfaces, and pin definitions. Labels such as test point numbers (TP7), "D+" and "D-" for USB ports, or "Pin1" for connectors significantly simplify debugging, testing, and inspection processes, reducing the risk of errors.

Then come certification symbols, branding, and version information. Marks like CE, UL logos, company logos, and PCB revision numbers (e.g., REV1.2) are vital for product compliance and traceability.

Finally, there is traceability data, a key element of modern smart manufacturing. This includes unique serial numbers, lot codes, and QR codes. A laser-engraved QR code can store vast amounts of information, allowing full lifecycle data traceability—from production materials to test records—with a simple scan.

Laser engraving technology is gradually replacing or complementing traditional screen printing due to its multifaceted, significant advantages that directly address the core demands of modern electronics manufacturing for quality, efficiency, and flexibility.

Unmatched Precision and Resolution: The laser spot diameter can reach the micron level, easily achieving characters and graphics as fine as 0.1mm or less. This allows for clear marking of reference designators for miniature components like 0402 or 0201, a feat difficult for screen printing.

Superior Permanence and Durability: Laser marks are formed through physical or chemical changes that bond directly with the substrate, giving them exceptional resistance to abrasion, chemical solvents, and high temperatures. They will not peel or fade during subsequent soldering, cleaning, or long-term use.

Consumable-Free, Eco-Friendlier Process: The entire process requires no inks, chemical etchants, or cleaning solvents and generates minimal physical waste, making it a clean, "green" manufacturing process that aligns with increasingly stringent environmental requirements.

Unparalleled Flexibility and Speed: Design changes only require modifying a computer file, with no need to recreate physical screens. For serialized marking with different numbers, it enables fully automated, personalized production where "every board is unique," with virtually zero downtime for model changeovers.

Excellent Compatibility and Adaptability: Whether it's common FR-4, high-frequency Rogers material, metal-core boards, or flexible circuits (FPC), lasers can find suitable parameters for high-quality marking, overcoming the poor adhesion issues screen printing faces with certain special substrates.

In the field of PCB laser engraving, two primary technological paths exist. They are like different types of "pens," each with its own specialty.

CO2 Lasers primarily interact with non-metallic materials. Their emitted infrared light is readily absorbed by the solder mask layer (green/white/black, etc.). By precisely controlling the energy, they can "burn away" the top layer of solder mask ink, revealing the underlying golden copper, creating a high-contrast mark. This method does not damage the copper layer and is relatively fast, making it the preferred choice for marking on solder mask.

Fiber Lasers are mainly used for direct marking on metal surfaces. Their wavelength is more easily absorbed by metals like copper and tin. They can create dark marks on exposed copper pads, HASL, or ENIG surfaces by inducing oxidation or altering the surface texture. They are also suitable for creating "light" marks on completed black solder mask layers.

For a clearer comparison of their differences and applications, refer to the table below:

| Characteristic | CO2 Laser Engraving | Fiber Laser Engraving |

|---|---|---|

| Target Material | Solder mask ink, polyimide, other non-metals | Copper, tin, gold, other metals |

| Marking Principle | Vaporizes solder mask, exposes underlying copper | Oxidizes, melts, or modifies the metal surface |

| Mark Color | Underlying copper color (golden) | Typically black or dark |

| Primary Application | Engraving component designators, QR codes on solder mask | Marking on bare copper pads or metalized surfaces |

| Key Advantage | High contrast, no copper damage, fast speed | Permanent mark, wear-resistant, works directly on metal |

A successful laser engraving is a seamless digital workflow bridging electronic design and production. The accuracy of the front-end design files is the cornerstone of the entire process.

First, dedicated files containing all silkscreen layer information need to be exported from PCB design software (like Altium Designer, KiCad). These files are then imported into laser marking software for critical post-processing setup: optimizing graphics and text (e.g., vectorizing complex logos, adjusting line width), planning the engraving path and sequence to maximize efficiency, and setting precise laser parameters (power, speed, frequency). This often requires process testing and refinement for different board materials and coatings.

Once the file is ready, the PCB is fixed on the engraving machine's worktable. A vision alignment system (CCD camera) automatically recognizes board edges or fiducial marks to ensure the engraving content aligns precisely with the PCB's pad pattern. Subsequently, the laser head begins scanning according to the pre-programmed path, with the entire process being fully automated. After engraving, a quick optical inspection is often performed to ensure all marks are clear and correct.

As electronic devices continue evolving toward miniaturization, high density, and three-dimensional forms, laser engraving technology is also innovating to meet new demands.

To address the challenge of increasingly dense components, ultra-fine engraving technology is developing. Utilizing cold processing technologies like UV picosecond lasers, it enables micron-scale, thermally damage-free marking, suitable for[敏感词]精密 applications like inside chip cavities.

Furthermore, 3D curved surface engraving technology is emerging. Through dynamic focusing systems, the laser can maintain its focal point on the curved surfaces of flexible circuits or 3D structural components, enabling conformal 3D marking and expanding its application boundaries.

Looking ahead, laser engraving will become deeply integrated with Industrial IoT and Artificial Intelligence. The engraved QR code will serve as the entry point for each circuit board into its digital twin system. AI algorithms will be able to analyze engraving quality in real-time and automatically adjust parameters for compensation, achieving truly adaptive, intelligent production. This promises to deliver[敏感词] quality and consistency while enhancing traceability.

Laser engraving, the art of painting with light, is becoming an indispensable part of modern high-end PCB manufacturing due to its irreplaceable precision, permanence, and flexibility. What it engraves is not merely a few characters or a QR code, but the traceable starting point of a product's life and a silent promise of manufacturing quality.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..