Date: 2025-12-23

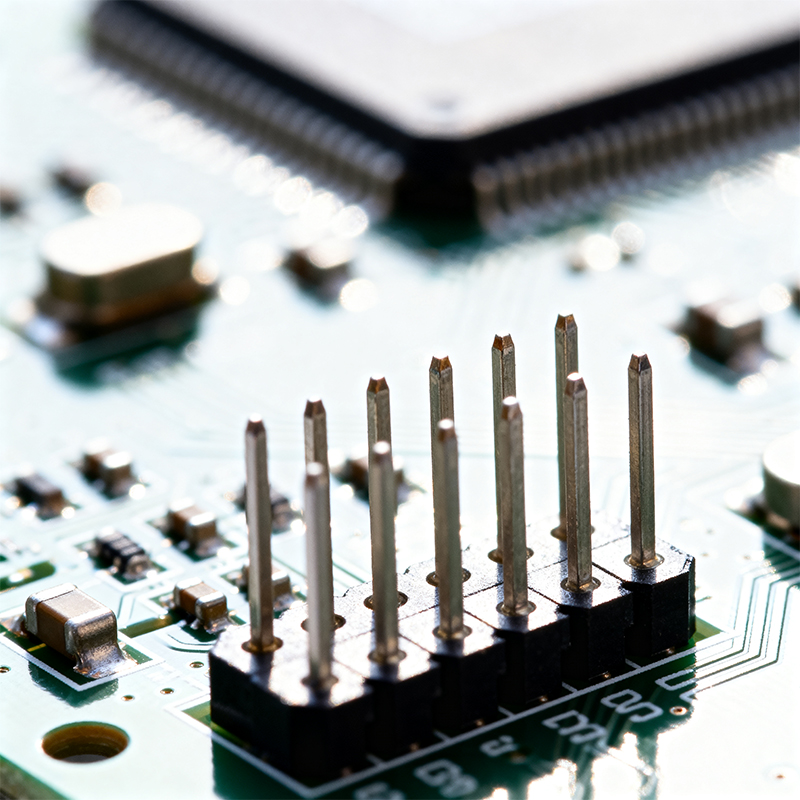

PCB pins are the physical interface points that extend from a printed circuit board, designed to create electrical connections between the board and external components, cables, or other circuit boards. These metallic protrusions serve as both electrical conductors and mechanical anchors, facilitating everything from power delivery to data transfer and physical mounting.

These pins establish electrical pathways:

Male Header Pins: Single or multi-row pins that insert into corresponding sockets

Female Sockets: Receptacles that receive male pins, commonly found on cables or daughter boards

Edge Connectors: Gold-plated contacts along the board's edge for slot-based connections

Test Points: Dedicated pads or raised pins for measurement equipment during debugging

These provide mechanical functions:

Standoffs: Raise the board above a surface for airflow or clearance

Alignment Pins: Ensure proper orientation during assembly

Mounting Pins: Secure the board to enclosures or chassis

Current Rating: Determined by pin cross-sectional area and material (typically 1-5A for standard pins)

Voltage Rating: Insulation and spacing requirements based on application

Contact Resistance: Quality pins maintain <20mΩ resistance per contact

Signal Integrity: Pin geometry affects impedance matching for high-speed signals

Insertion Force: The pressure required to mate pins (typically 0.5-2.5N per pin)

Durability: Rated mating cycles range from 50 (consumer) to 1000+ (military)

Retention Force: Resistance to accidental disconnection

Operating Temperature: Commercial (-10°C to +60°C) to industrial (-40°C to +85°C) ranges

Brass: Cost-effective with good spring properties

Phosphor Bronze: Better durability and conductivity

Beryllium Copper: High strength and excellent conductivity

Steel: Maximum mechanical strength

Tin Plating: Economical but prone to oxidation

Gold Over Nickel: Excellent corrosion resistance and conductivity

Selective Gold Plating: Gold only on contact areas to reduce cost

Silver: High conductivity but requires anti-tarnish treatment

Pin Spacing: Standard pitches include 2.54mm (0.1"), 2.00mm, and 1.27mm

Clearance Requirements: Space for mating connectors and hand access

Routing Priorities: Critical signals positioned near ground pins

Assembly Access: Ensuring pins don't block other components during manufacturing

Current Paths: Adequate pin count for power delivery to prevent overheating

Signal Integrity: Ground pins adjacent to high-speed signals to control impedance

Mechanical Stress: Reinforcement for pins experiencing frequent mating cycles

Thermal Management: Pin selection considering heat dissipation requirements

Pins inserted into drilled holes and soldered on the opposite side

Excellent mechanical strength

Requires wave or selective soldering

Additional drilling increases board cost

Pins soldered directly to surface pads

Enables automated assembly

Lower profile but reduced mechanical strength

Requires precise placement and reflow profiling

Pins pressed into plated through-holes with interference fit

No soldering required

Excellent reliability for high-vibration environments

Requires precise hole size control

Requirements: High current capacity, secure mechanical connection

Typical Pins: Heavy-duty terminals, multi-pin power connectors

Considerations: Voltage rating, insulation, thermal management

Requirements: Controlled impedance, shielding, precise alignment

Typical Pins: Multi-pin headers, edge connectors, coaxial pins

Considerations: Signal speed, crosstalk prevention, EMI shielding

Requirements: Reliable mating, space efficiency, proper alignment

Typical Pins: Stacking headers, mezzanine connectors

Considerations: Height restrictions, board spacing, thermal expansion

Continuity Verification: Ensures pins are properly connected to circuit traces

Insulation Resistance: Tests isolation between adjacent pins (>100MΩ typically)

Current Carrying Tests: Validates pins can handle rated current without overheating

Contact Resistance Measurement: Confirms low-resistance connections (<20mΩ)

Insertion/Extraction Force: Measured with calibrated force gauges

Durability Testing: Repeated mating cycles to verify pin longevity

Environmental Testing: Exposure to temperature cycles, humidity, and vibration

Retention Force Testing: Ensures pins remain connected under specified conditions

UL Certification: Safety requirements for electrical connections

IEC Specifications: International standards for connector performance

RoHS Compliance: Restrictions on hazardous substances

REACH Compliance: Chemical registration and usage regulations

Automotive: Vibration resistance, temperature extremes, moisture protection

Aerospace/Military: Extreme reliability, wide temperature ranges, shock resistance

Medical: Biocompatibility, sterilization compatibility, high reliability

Industrial: Durability, environmental sealing, maintenance accessibility

Define Electrical Requirements: Current, voltage, signal types

Determine Mechanical Needs: Mating cycles, environmental conditions

Evaluate Space Constraints: Board real estate, height restrictions

Consider Assembly Methods: Compatibility with manufacturing processes

Analyze Lifecycle Factors: Availability, cost, replacement needs

Undersizing Power Pins: Leads to overheating and connection failure

Ignoring Mating Cycles: Using consumer-grade pins in industrial applications

Poor Pin Layout: Creating assembly difficulties or signal interference

Material Incompatibility: Galvanic corrosion from dissimilar metals

Inadequate Strain Relief: Cable connections that damage board traces

Ultra-fine pitch pins (<0.5mm spacing)

Micro-pins for high-density interconnects

Board-embedded pin structures

High-temperature plastics for housings

Improved contact coatings for durability

Sustainable and recyclable materials

Pins with embedded sensing capabilities

Self-diagnosing connection systems

Integrated signal conditioning

PCB pins represent a critical interface between electronic circuits and the physical world. Their proper selection and implementation require balancing electrical requirements, mechanical demands, manufacturing considerations, and cost constraints. While often considered simple components, pins significantly impact product reliability, performance, and manufacturability.

Successful pin implementation begins with understanding application requirements and continues through careful design, material selection, and verification testing. As electronic systems continue evolving toward higher density and greater complexity, pin technology must advance accordingly, maintaining the essential connection between innovation and practical implementation.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..