Date: 2025-11-01

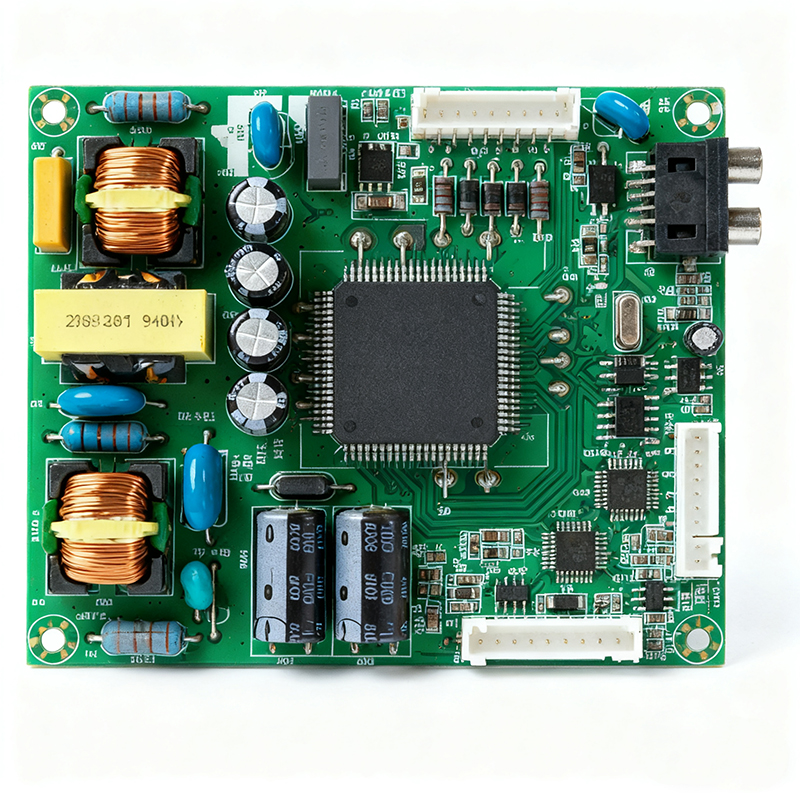

Let's be real - trying to place those microscopic components on your PCBA is like performing surgery with oven mitts. When you're working with 0201 or 01005 sized parts, even the tiniest misalignment can ruin your entire board. We see this daily with miniaturized electronics where precision is everything.

Here's what's actually happening and how we're solving it:

The challenge is that traditional placement machines can't always account for board warping, component variations, or microscopic positioning errors. It's like trying to park a car blindfolded - you're bound to be off by a few inches (or in this case, micrometers).

So here's our two-part solution:

We use high-resolution cameras that act like super-powered eyes, scanning every component and PCB marker in real-time. Then our system makes instant adjustments to correct any positioning errors before placement happens. It's like having a skilled surgeon who can adjust their movements mid-operation.

When you work with us:

We'll explain it simply: "Our cameras check each component's position 100 times per second and adjust the placement head to compensate for any misalignment." No confusing technical manuals needed.

We customize the system for your specific components. Working with ultra-small chips? Fine-pitch connectors? We've handled the most challenging placements and know how to adapt.

You'll see actual placement accuracy reports and before-and-after comparison photos. We believe in showing you the evidence, not just making claims.

Why this approach actually matters:

Your tiny components go down right the first time

Your production yield jumps up significantly

You save money by eliminating rework and scrap

The results speak for themselves - we're achieving 99.8% placement accuracy with this method. The visual system catches errors humans would miss, while the dynamic compensation adjusts for real-world variables like board warping.

We use this for everything from wearable devices and medical implants to consumer electronics where every micron counts.

If you're tired of placement errors ruining your PCBA production, this camera-guided system could be your solution. We're helping manufacturers place even the smallest components with incredible precision. Your boards work better, your production runs smoother, and you can finally stop worrying about those frustrating misalignment issues.

We've helped companies across multiple industries solve their miniature component placement challenges. The technology exists - you just need a partner who knows how to make it work for your specific components and production requirements.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..