Date: 2025-11-13

Let's cut to the chase - when your electronics need to handle heat, aluminum PCBs aren't just nice to have, they're essential. They pull heat away from your components, keep everything running stable, and stop your products from dying an early death. But choosing the right supplier isn't about comparing specs - it's about finding a partner who actually makes these boards work in the real world.

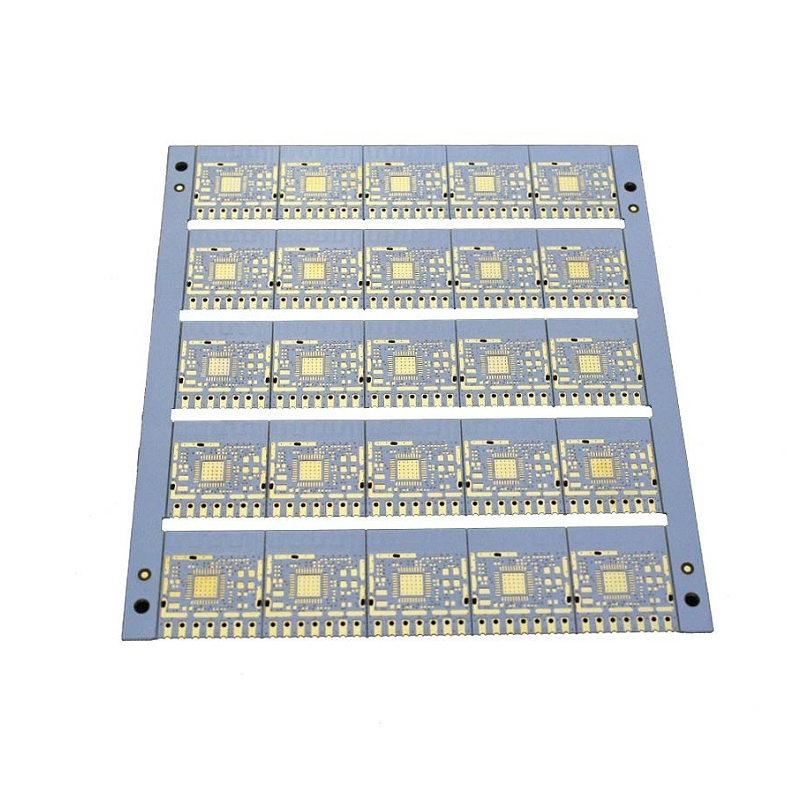

At Kaboer, we don't just make aluminum boards - we make sure they solve your actual problems. Here's what to look for when you're choosing who to work with.

1. Manufacturing That Actually Works

Your supplier needs to make boards that do their job properly:

Heat Management That Doesn't Quit

The whole point is keeping things cool. Can your supplier consistently hit the thermal conductivity you need? For regular electronics, you might need 1.0 W/m·K, but for high-power LEDs, you're looking at 2.0-5.0 W/m·K. At Kaboer, we make sure heat gets away from your sensitive components before they start acting up.

Insulation That Won't Let You Down

These boards need to conduct heat but block electricity. Will they stay that way when things get hot and humid? We build ours to handle at least 2kV breakdown voltage - no shorts, no surprises.

Boards That Fit Your Actual Product

Can they make the size and shape you need? Thin boards for tight spaces, rigid ones for industrial gear? We customize because your product isn't one-size-fits-all.

2. Quality Control You Can Trust

Your production can't handle boards that work differently every time:

Testing What Actually Matters

Does your supplier check every batch for thermal performance, insulation, and how well everything sticks together? We test all three because leaving out any one is like shipping a car without checking the brakes.

Boards That Last

We put our boards through heat cycling and humidity tests because your products don't live in a perfect lab environment. They need to work year after year.

No Compliance Surprises

RoHS, REACH, UL - we're up to date on all the regulations so your products can ship anywhere without getting held up.

3. Support That Solves Problems

The best board won't help if you can't make it work in your product:

Customization That Makes Sense

Sometimes you need better heat spreading, other times you need lighter weight. We'll adjust the recipe to match what you're building.

Help When You Need It

Stuck on how to mount the board? Not sure about thermal design? Our team speaks your language and we're here to help make your product work better.

Quick Fixes When Things Go Wrong

If you hit a snag, we're available to help sort it out fast. Downtime costs money and we get that.

Why Kaboer Actually Delivers

Here's what makes us different:

We focus on what aluminum PCBs are supposed to do - manage heat, provide reliable insulation, and fit your design. Everything we do comes back to these core functions.

Our quality control starts with performance testing. We make sure every board does its job, every time.

We don't just sell you boards - we help you get the most out of them. Stuck on a thermal issue? Space too tight? We'll work with you to find a solution.

We get boards to you on time, anywhere in the world, and they'll perform exactly like the last batch.

The Bottom Line

Choosing an aluminum PCB supplier comes down to finding someone who understands that these boards need to work reliably in the real world. At Kaboer, we combine solid manufacturing with real-world testing and actual support to make sure your products run cooler and last longer.

Whether you're building LED lighting, power electronics, or automotive systems, we're the partner who won't let you down when the heat is on. Let's talk about how we can help with your next project.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..