Date: 2025-12-27

Printed Circuit Board (PCB) Fuses are critical, small-form-factor safety devices mounted directly on a circuit board. Their primary function is to protect electronic circuits and equipment from damage caused by overcurrent conditions, such as short circuits or excessive load. They achieve this by intentionally containing a fusible element (a metal wire or strip) that melts and opens the circuit when current exceeds a specified rating for a defined time, thereby interrupting the flow of electricity and preventing potential fire or component failure.

For electronics manufacturers, selecting and implementing the correct PCB fuse is a fundamental aspect of designing safe, reliable, and compliant products. This guide provides a comprehensive overview of PCB fuse types, operating principles, and key selection criteria.

A fuse operates on a simple thermal principle. The fusible link is a calibrated conductor with a specific resistance. Under normal operating current, the heat generated by this resistance (I²R) is insufficient to melt the link. When an overcurrent occurs, the heat generation increases dramatically, raising the temperature of the fusible link past its melting point. This causes it to fail open circuit, creating a permanent break in the electrical path. Once a traditional fuse "blows," it must be replaced.

PCB fuses come in various form factors and technologies to suit different applications.

| Type | Description & Construction | Key Characteristics |

|---|---|---|

| Surface Mount Device (SMD) Fuses | Miniature, rectangular chips designed for automated pick-and-place assembly. They contain the fusible element within a ceramic or plastic package with metal end caps. | Extremely compact, ideal for high-density modern electronics. Available in standard chip sizes (e.g., 1206, 0603). Limited interrupt rating. |

| Through-Hole (Radial/Axial) Fuses | Cylindrical glass or ceramic tube fuses with metal end caps and axial/radial leads for insertion into PCB holes. The fusible wire is visible inside the tube. | Easy to inspect visually after failure. Generally offer higher interrupt ratings than SMD types. Requires manual or special insertion. |

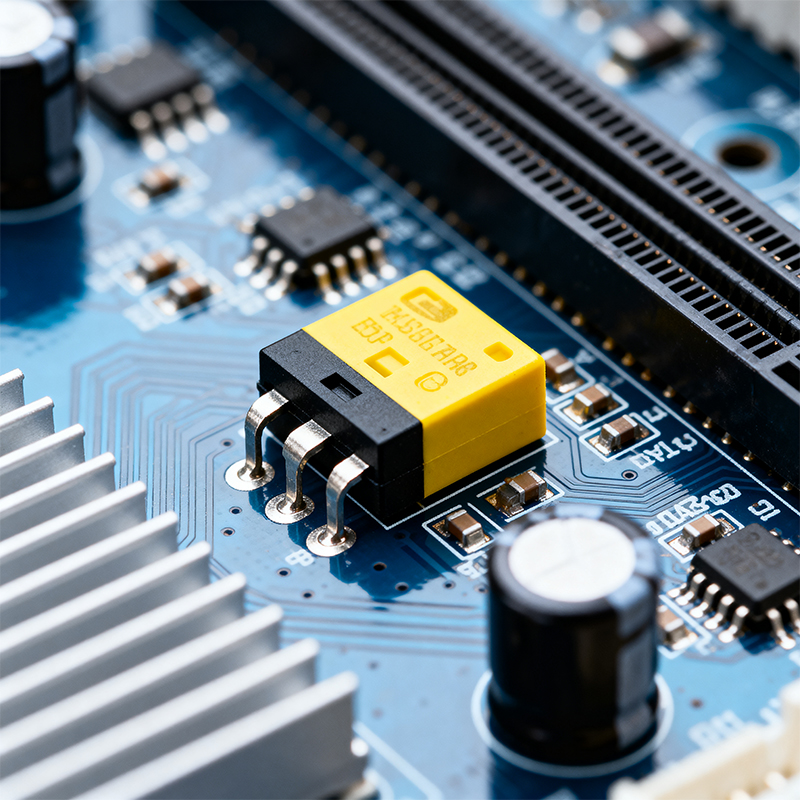

| Resettable Fuses (PPTC/Polyfuse) | Polymer Positive Temperature Coefficient devices. They are not fuses in the traditional sense but resettable overcurrent protectors. A polymer composite with conductive particles exhibits a sharp increase in resistance ("trip") when overheated by overcurrent. | Self-resetting. After the fault is removed and the device cools, it returns to a low-resistance state. Excellent for protecting against temporary faults. Higher resistance and slower response than traditional fuses. |

Choosing the right fuse involves analyzing several critical parameters from the datasheet:

Rated Current (I_n): The maximum continuous current the fuse can carry without opening. Derating is essential—typically, operate at no more than 75% of I_n at 25°C ambient temperature.

Rated Voltage (V_n): The maximum circuit voltage the open fuse can safely withstand without arcing or re-establishing current.

Breaking Capacity/Interrupt Rating: The maximum fault current the fuse can safely interrupt without rupturing, exploding, or causing a fire. Must be higher than the available short-circuit current in the system.

Time-Current Characteristic (Speed): Defines how quickly the fuse opens under overcurrent. Fast-Acting (quick blow) fuses protect sensitive semiconductors. Slow-Blow (time-delay) fuses tolerate temporary inrush currents (e.g., from motor starts or capacitor charging) without nuisance blowing.

Operating Temperature: Fuse performance is temperature-sensitive. A fuse will blow at a lower current in a hot environment. The datasheet provides derating curves.

Resistance (R): The inherent resistance of the fuse contributes to power loss (I²R). Critical for low-voltage, high-current applications.

Location: Place the fuse as close as possible to the power entry point of the circuit it is protecting (e.g., immediately after the DC input connector or battery). This protects all downstream components and traces.

Trace Design: The PCB traces leading to and from the fuse must be wide enough to handle the full rated current and fault current without overheating. Fuse pads should be thermally relieved if necessary.

Accessibility & Marking: For user-replaceable fuses (through-hole), ensure physical access. Clearly label the fuse rating (F1: 2A 250V) on the PCB silkscreen.

Testing & Safety Standards: Fuses are safety-critical components. Ensure they carry certifications from relevant bodies (e.g., UL/CSA, IEC, PSE) for the target market. Design verification should include fault condition testing to validate fuse operation.

Primary DC Input Protection: The first component after the power jack or battery terminals.

Subsystem/Module Protection: Isolating individual circuit blocks (e.g., a motor driver, a high-power LED array, or a peripheral USB port) to prevent a local fault from disabling the entire system.

Interface Protection: On ports (USB, HDMI) to protect the host device from faults on connected cables or peripherals.

Overcurrent Protection for ICs: Using miniature SMD fuses to protect specific voltage rails powering sensitive ASICs or processors.

Q1: Can I replace a blown SMD fuse with a wire or a higher-rated fuse?

A: Absolutely not. This is extremely dangerous. "Jumpering" a fuse or using an incorrect rating removes the designed protection, creating a serious fire and shock hazard. Always replace with an identical, manufacturer-specified part.

Q2: What is the difference between a fuse and a circuit breaker on a PCB?

A: A fuse is a one-time-use, sacrificial device. A PCB-mountable circuit breaker is a resettable electromechanical switch that trips on overcurrent and can be manually or automatically reset. Breakers are used where manual intervention is acceptable and frequent faults are expected (e.g., in some industrial controls).

Q3: How do I test if a PCB fuse is still good?

A: Use a multimeter in continuity or resistance mode. A good fuse will show very low resistance (near 0 ohms). A blown fuse will show "OL" (open loop) or infinite resistance. Always remove power from the circuit before testing.

Q4: Why did my properly rated fuse blow unexpectedly during normal operation?

A: Common causes include: Inrush Current (consider a slow-blow fuse), Excess Ambient Temperature (check derating), Pulsing/Intermittent Loads causing thermal fatigue, or a marginal/aging component elsewhere in the circuit drawing slightly excess current.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..