Date: 2026-01-09

There's a good chance your latest design calls for a surface mount PCB board. Most modern electronics do. SMT technology is what makes today's compact, powerful devices possible, from smartphones to industrial sensors.

Moving to surface mount or refining your SMT process brings a specific set of questions. It's less about if you should use it and more about how to get it done reliably.

You likely know the textbook benefits: smaller boards, higher component density, and suitability for automation. The real-world value, however, hits home in production:

Scalability: A well-tuned SMT line can move from prototyping to volume production with consistent results. The bottleneck shifts from manual labor to machine throughput and material flow.

Repeatability: Once the stencil, placement program, and reflow profile are dialed in, every board should come out virtually identical. This consistency is crucial for quality and reliability.

Component Availability: The vast majority of new, high-performance components are released only as SMD packages. Designing with surface mount opens up your options.

Success with surface mount assembly hinges on anticipating common pitfalls. Issues rarely come from the concept itself, but from the execution.

The Design Gap: A board that looks perfect in CAD can be difficult or expensive to manufacture. Think of components placed too close for proper solder paste inspection, or thermal pads without adequate venting. This is why Design for Manufacturability (DFM) review isn't a luxury—it's a necessity.

The "Ghost in the Machine": Even with perfect files, the wrong stencil thickness, an inaccurate reflow profile, or a misaligned pick-and-place head can cause defects. Bridging, tombstoning, and cold solder joints are often process issues, not design flaws.

Supply Chain Surprises: Specifying a tiny 0201 resistor or a specific BGA is one thing. Ensuring a steady, authentic supply of those parts for a 10,000-unit run is another challenge entirely.

When evaluating a partner for your surface mount PCB board, their checklist should be transparent. Key items include:

DFM Analysis: Do they provide a formal report highlighting potential issues before fabrication begins?

Process Control: Can they articulate their solder paste management, stencil protocols, and how they establish reflow profiles?

Inspection Capability: Do they rely solely on human eyes, or do they use Automated Optical Inspection (AOI) and X-ray for hidden joints (like on BGAs)?

Component Sourcing: Do they have the procurement leverage and quality controls to source genuine parts and manage shortages?

At our factory in Shenzhen, we see our role as problem-solvers for these exact challenges. We build reliability into the process from the start.

For every surface mount PCB board project, our workflow is built on clarity and prevention:

We Start with a Review: Before any commitment, our engineering team examines your Gerber and BOM files. We look for potential manufacturing issues and suggest optimizations. This initial conversation often saves significant time and cost down the line.

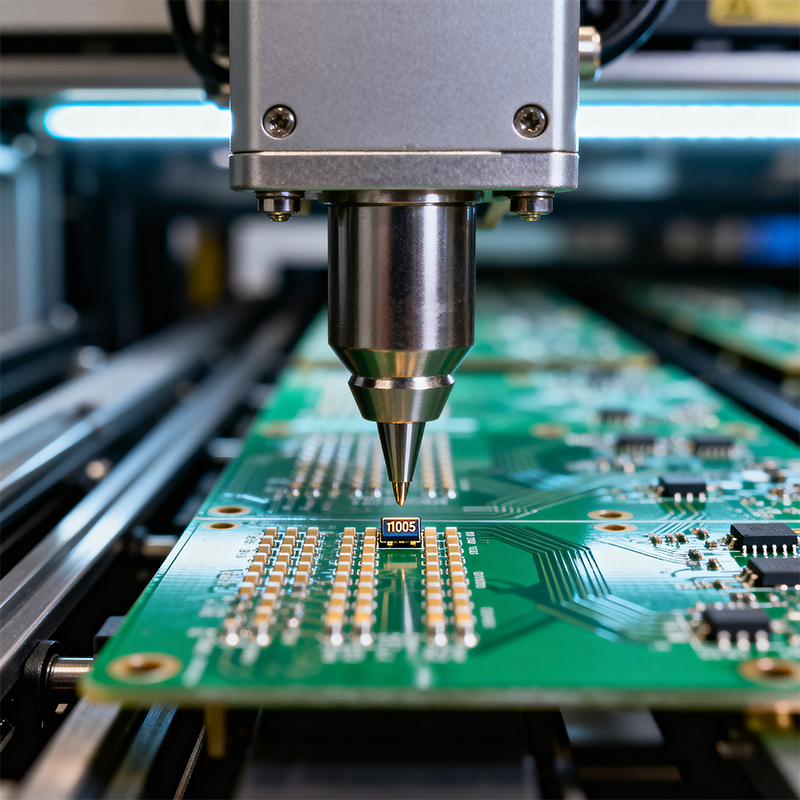

We Control the Process: From precision stencil printing on our MPC machines to high-speed placement with Yamaha equipment, we monitor critical parameters in real-time. Our reflow ovens use profiling to match the exact thermal needs of your board.

We Verify Obsessively: AOI systems check every placed component after soldering. For complex packages, X-ray inspection verifies solder joints you can't see. This data-driven approach catches issues that manual inspection would miss.

We Manage the Headaches: Leveraging our location in the global electronics hub, we handle the entire component procurement, logistics, and inventory burden. You get a single quote for a fully assembled, tested board.

The best manufacturing partner aligns with your stage and goals. A quick-turn proto house is great for early concepts. But when your design stabilizes and volumes increase, you need a partner with robust process controls and supply chain depth.

If you're moving beyond the initial prototype phase and need a partner who understands that building a great surface mount PCB board is about meticulous process management, let's talk. We help teams translate complex designs into dependable, mass-producible hardware.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..