Date: 2025-11-11

The push for more powerful electronics - from electric car motor controllers to 5G base stations and industrial drives - is driving a quiet revolution in aluminum substrate technology. We're seeing two major breakthroughs happen at once: boards are getting incredibly thin (≤0.5mm) while achieving thermal conductivity that was once thought impossible (≥10 W/m·K). Here's how it's happening and why it matters.

1. Smarter Materials: Beating the Old Limits

The magic starts at the material level.

Better Insulation Layers:

Forget the standard stuff. Now we're using epoxy filled with nano-scale ceramic particles (alumina or boron nitride). This simple-sounding upgrade can triple the thermal performance of the insulation layer. One manufacturer using an 80μm boron nitride-filled layer cut thermal resistance by 33% compared to conventional materials.

Even more advanced: some are embedding graphene films within the insulation. This creates a "superhighway" for heat to spread sideways across the board, dramatically improving temperature uniformity.

For really tough environments (like under a car hood), high-temperature polyimide materials can now handle 260°C with better voltage protection and less risk of cracking from heat stress.

Smarter Metal Cores:

Pure aluminum is good, but aluminum-copper composites are better. By embedding a thin copper layer into the aluminum core, manufacturers are getting 50% better heat spreading while keeping most of aluminum's weight advantage - and at 30% lower cost than solid copper.

For extreme applications (think aerospace), new manufacturing techniques are creating graphene-reinforced aluminum alloys that are both stronger and better at conducting heat.

2. Smarter Designs: Building 3D Cooling Networks

It's not just what they're made of, but how they're designed.

Direct Heat Pathways:

The best new designs put heat on an "express route" to the metal core. They use solid copper pads under hot components, connected directly to the aluminum base with arrays of small vias. This can cut the thermal resistance in half compared to traditional designs.

"Thermal-electrical separation" is another clever trick - keeping power and signal lines physically separate with dedicated cooling paths for hot components like IGBTs. This not only improves cooling but reduces electrical noise.

Superior Temperature Spreading:

Instead of just moving heat downward, new designs spread it sideways efficiently. "Main artery + capillary" copper networks can keep multiple chips within 5°C of each other, compared to 15°C differences in older designs. This prevents hot spots that kill component lifespan.

Some are even incorporating graphene-aluminum composite heat spreaders that work like miniature, ultra-light heat pipes built right into the board - perfect for weight-sensitive applications like automotive radar.

3. Precision Manufacturing: Making It Work Consistently

These advanced designs require equally advanced manufacturing.

Thinner, Better Layers:

Manufacturers are now reliably producing insulation layers as thin as 30-80μm while maintaining high voltage protection. One company makes a 0.3mm thick aluminum board with an 80μm insulation layer that still handles 3000V.

Better surface treatments ensure the copper stays firmly bonded to the aluminum through thousands of temperature cycles.

Micro-Scale Precision:

Laser drilling with ±2μm accuracy creates perfect microscopic vias. Advanced coatings on the aluminum itself can now enhance both conduction and radiation cooling - particularly useful in sealed environments without fans.

4. Why This Matters in the Real World

The improvements aren't just theoretical:

In tests, optimized aluminum boards run 15°C cooler under the same power load, potentially tripling the lifespan of components.

The 0.5mm ultra-thin versions are 60% lighter than traditional 1.5mm boards, enabling thinner smartphones, wearables, and drones.

In many cases, the metal core can serve as part of the enclosure, eliminating separate heat sinks and saving both space and cost.

Where You'll See This Technology:

Electric Vehicles: Motor controllers keeping IGBTs cool enough for 800V systems; LED headlights that maintain brightness years longer.

5G Infrastructure: Base station components that handle 200W+ power densities reliably across extreme temperature ranges.

Industrial Equipment: Variable frequency drives that run cooler and last longer, with better vibration resistance.

What's Coming Next:

The future looks even more integrated. We're seeing:

Hybrid materials combining aluminum with ceramics for extraordinary thermal performance

"Smart" boards with embedded sensors that actively manage their own temperature

Greener manufacturing with higher recyclability and less chemical waste

The Bottom Line:

Aluminum substrates have evolved from simple carriers into sophisticated thermal management systems. As electronics continue to push power limits in smaller packages, these advanced aluminum boards - thin enough to fit anywhere yet capable of handling serious heat - will be the unsung heroes enabling tomorrow's technology. The market is recognizing this too, with projected growth exceeding 20% annually as these solutions become essential across multiple industries.

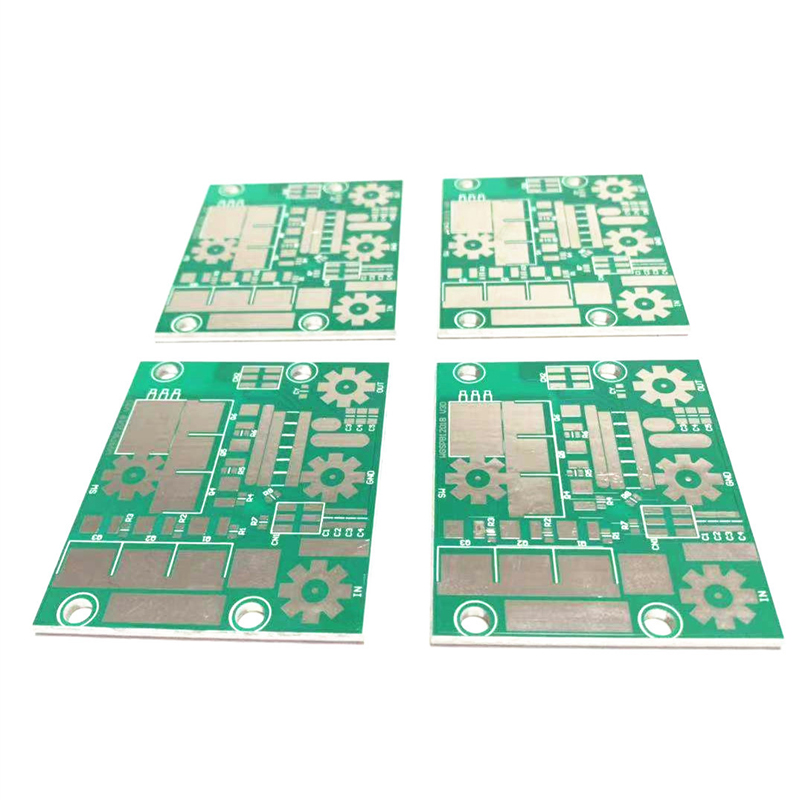

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..