Flexible printed circuits (FPCs) are the quiet revolutionaries of modern electronics, enabling devices to bend, twist, and fit into spaces once thought impossible. From the foldable screens of the latest smartphones to the intricate wiring of medical pacemakers, FPCs have become indispensable. But where did this technology begin? Its journey from experimental prototypes to mass-produced essentials is a story of innovation, necessity, and the relentless drive to make electronics more adaptable.

Let’s trace the origins, key milestones, and transformative moments that shaped FPCs into the critical components they are today—essential knowledge for engineers, manufacturers, and anyone curious about the tech that powers our connected world.

The Early Days: Birth of a Flexible Idea (1950s–1960s)

The concept of flexible circuits emerged not from consumer electronics, but from the demands of aerospace and defense. In the 1950s, as rockets and early satellites grew more complex, engineers faced a pressing problem: rigid printed circuit boards (PCBs) were heavy, bulky, and couldn’t conform to the curved, space-constrained interiors of aircraft and spacecraft.

-

1950s Experiments: Researchers at companies like Boeing and Hughes Aircraft began experimenting with conductive inks printed on flexible substrates (like Mylar) to create lightweight, moldable circuits. These early versions were crude—more like "flexible wires" than structured circuits—but they proved that conductivity didn’t require rigidity.

-

1961: First Patent: The first formal patent for a "flexible electrical circuit" was filed by Albert Berry, an engineer at the U.S. Army Signal Corps. His design used copper foil bonded to a polyimide film, a precursor to modern FPC materials. This patent laid the groundwork for combining flexibility with the structural integrity needed for reliable performance.

-

1960s Aerospace Adoption: By the late 1960s, NASA’s Apollo program adopted early FPCs in spacecraft instrumentation. Their light weight (up to 70% lighter than rigid PCBs) and ability to fit into tight compartments made them ideal for reducing launch payloads—a critical advantage in an era of limited rocket power.

The Polyimide Breakthrough: Enabling Durability (1970s–1980s)

The 1970s marked a turning point for FPCs, thanks to a material innovation: polyimide (PI) film. Developed by DuPont in the 1960s under the trade name Kapton, PI offered a rare combination of properties that solved early FPC weaknesses:

-

Heat Resistance: PI withstands temperatures from -269°C to 400°C, making it suitable for high-heat environments like engine bays and industrial machinery—areas where earlier Mylar-based circuits failed.

-

Chemical Stability: Unlike paper or cellulose substrates, PI resisted degradation from oils, solvents, and humidity, expanding FPC use into harsh industrial settings.

-

Mechanical Strength: Thin (25μm–125μm) PI films maintained flexibility while providing a stable base for copper traces, enabling more complex circuit designs.

By the 1980s, PI-based FPCs began migrating beyond aerospace into consumer electronics. Early applications included:

-

Camcorders: Sony’s Handycam used FPCs to connect the viewfinder to the main body, allowing the screen to swivel without damaging wires.

-

Calculators and Watches: Thin FPCs enabled slimmer designs in devices like Casio’s pocket calculators, replacing bulky wire harnesses with compact, flexible circuits.

Mass Production and Miniaturization (1990s–2000s)

The 1990s and 2000s saw FPCs transition from niche components to mass-produced essentials, driven by two trends: the rise of mobile devices and advances in manufacturing technology.

-

Roll-to-Roll Manufacturing: Innovations in roll-to-roll processing—where continuous sheets of PI are coated with copper, etched, and laminated in a single line—reduced production costs by 50%+ and enabled high-volume output. This made FPCs affordable for devices like flip phones and digital cameras.

-

Smartphones and the "Thin Is In" Era: As phones shrank from brick-sized devices to pocket-sized gadgets, FPCs became the only way to connect components (screens, cameras, batteries) in tight spaces. The first iPhone (2007) used over a dozen FPCs, including flexible cables for its touchscreen and accelerometer.

-

Medical Devices: FPCs found a critical role in minimally invasive medical tools. Endoscopes, for example, use ultra-thin FPCs to carry video signals from tiny cameras to external monitors, bending through the body’s natural curves without breaking.

2010s–Present: Flexibility Redefined

The last decade has pushed FPC technology to new extremes, driven by demand for foldable devices, wearables, and IoT sensors. Key advancements include:

-

Foldable Displays: Samsung’s Galaxy Z Fold (2019) and Motorola’s Razr (2020) rely on "bendable FPCs"—reinforced with rolled annealed (RA) copper and thin PI substrates—that survive 200,000+ folds. These FPCs use serpentine trace patterns to distribute stress, a design inspired by early aerospace flex circuits.

-

Wearables: Fitness trackers (Fitbit), smartwatches (Apple Watch), and health patches use FPCs to conform to the body. Modern FPCs here are as thin as 0.05mm, with biocompatible coatings that resist sweat and skin oils.

-

5G and High-Speed Data: To handle 5G’s mmWave frequencies (24GHz–40GHz), FPCs now use liquid crystal polymer (LCP) substrates, which minimize signal loss better than PI. This makes them essential for 5G antennas in smartphones and IoT devices.

Global Production: From U.S. Labs to Worldwide Networks

While FPCs trace their roots to U.S. aerospace research, production has globalized:

-

Japan: Companies like Nitto Denko and Fujikura dominate high-end FPCs for automotive and medical use, emphasizing precision and reliability.

-

South Korea: Samsung Electro-Mechanics leads in foldable phone FPCs, supplying its parent company’s Z-series devices.

-

China: Manufacturers like Kaboer、Zhen Ding Technology (ZDT) focus on high-volume, cost-effective FPCs for consumer electronics, driving down prices for global brands.

-

U.S. Innovation: American firms like Flex and TT Electronics specialize in custom FPCs for aerospace, defense, and medical sectors, leveraging advanced materials like Parylene-coated circuits for biocompatibility.

The Future: Stretching the Limits

Today, FPCs are evolving beyond "flexible" to "stretchable." Researchers are developing circuits using elastomeric substrates and conductive inks that can stretch by 300%—opening doors for:

-

Skin-like Sensors: Wearable patches that monitor vital signs while stretching with the skin during movement.

-

Soft Robotics: Flexible circuits that power robotic grippers, enabling them to handle delicate objects like fruits or human tissue.

-

Integrated Energy Harvesting: FPCs combined with flexible solar cells or piezoelectric materials, allowing devices to charge from movement or light.

Conclusion: A Legacy of Adaptability

The story of FPCs is one of solving problems by reimagining what circuits can be. From their origins in 1950s aerospace labs to their role in today’s foldable phones, FPCs have always been defined by adaptability—adapting to new materials, new manufacturing methods, and new demands.

For engineers and innovators, understanding this history isn’t just about nostalgia. It’s a reminder that the next breakthrough in electronics—whether in AI, quantum computing, or beyond—will likely rely on FPCs, continuing their legacy as the unsung enablers of technological progress.

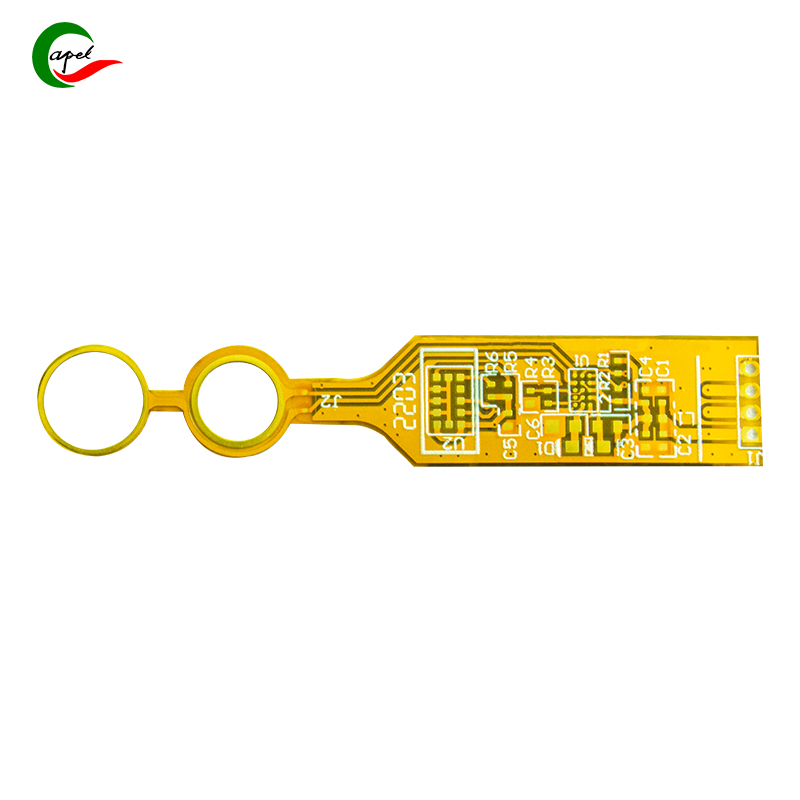

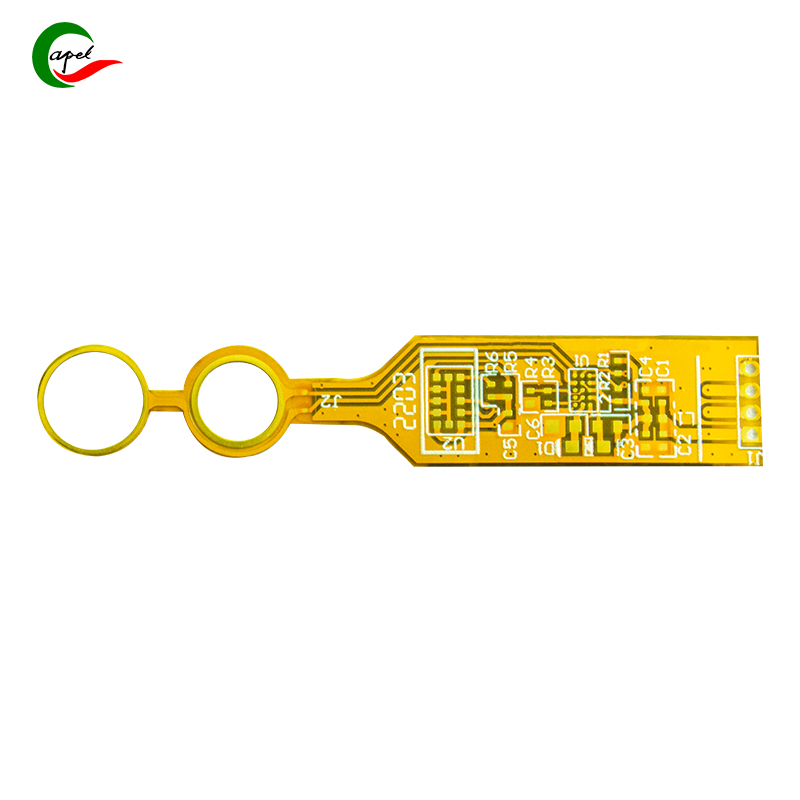

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.