Date: 2025-08-29

Look around. Your phone knows which way is up. Your car warns you of a blind-spot vehicle. Your smartwatch tracks your heartbeat. This isn't magic; it's the work of smart sensor modules—the unsung heroes of modern electronics. But these modules face a constant squeeze: they must be smaller, more reliable, and packed with more features than ever. So, how do engineers solve this puzzle? The answer often lies not just in the sensors themselves, but in the hidden technology that connects them: the Rigid-Flex PCB.

Part 1: The "Aha!" Moment - What is a Rigid-Flex PCB?

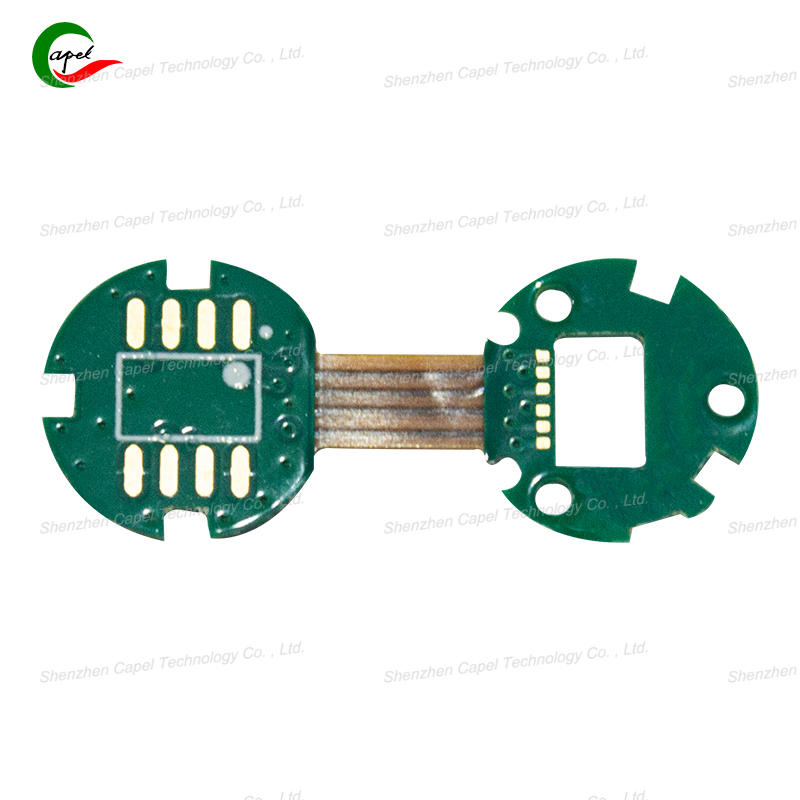

Imagine a printed circuit board that refuses to be boxed in. It has the sturdy, familiar strength of a standard PCB (the "rigid" part) perfectly integrated with thin, flexible circuits (the "flex" part) that can bend, fold, and twist. This isn't just connecting two separate boards with a cable; it's a single, continuous, and monolithic circuit fabricated as one unified structure.

Think of it like the spine of a book. The rigid sections are the hardcover boards, providing structure and housing the heavy components (processors, connectors). The flexible sections are the pages, allowing the entire assembly to bend and move without breaking. This hybrid approach is revolutionizing how we design electronic assemblies.

Part 2: The Smart Sensor Squeeze: Why Traditional PCBs Fall Short

Smart sensor modules are deployed in some of the most demanding environments:

Inside a vibrating industrial motor

Within the curved bezel of a smartphone

On a rotating camera gimbal

Inside a wearable device on your wrist

Traditional wiring solutions struggle here:

The Cable Conundrum: Using separate rigid PCBs connected by wires or connectors creates a bulky package. Connectors are a common point of failure, susceptible to corrosion and coming loose from vibration.

The Space Paradox: Standard rigid boards can't easily conform to tight, irregular spaces, wasting precious volume that could be used for a larger battery or more features.

The Reliability Risk: Every connector and solder joint between boards is a potential point of failure, especially under mechanical stress or thermal cycling.

Part 3: The Rigid-Flex Advantage: Simplifying Wiring and Boosting Integration

This is where Rigid-Flex PCBs shine. They are the ultimate problem-solvers for compact, complex electronics.

1. Simplifying Wiring and Assembly:

Bye-Bye, Connectors: The most obvious benefit. By eliminating many connectors and discrete wires, the design is radically simplified. This means:

Fewer Components: A smaller Bill of Materials (BOM), reducing cost and sourcing complexity.

Faster Assembly: Automated assembly is easier and more reliable without the need to manually connect multiple boards and cables.

Reduced Weight: No connectors and less housing material mean a lighter end product—a critical factor in aerospace and automotive applications.

2. Dramatically Enhancing Integration:

3D Freedom: This is the superpower of Rigid-Flex. Designers can fold the electronics into the available space, like architectural origami. This allows for incredibly efficient use of the Z-axis (height), enabling smaller, slimmer, and more ergonomic product designs that were previously impossible.

Improved Signal Integrity: High-speed data from sensors (like image data from a camera) is vulnerable to noise and interference. The embedded traces in a flex circuit are shorter and better controlled than external cables. With proper impedance control, Rigid-Flex minimizes signal loss and electromagnetic interference (EMI), leading to cleaner data and better performance.

Enhanced Reliability and Durability: A monolithic Rigid-Flex board is inherently more robust. Without connectors that can work loose and wires that can fray, it can withstand millions of flex cycles, severe vibrations, and extreme temperature swings. This is why they are trusted in medical devices, automotive systems, and aerospace applications where failure is not an option.

Part 4: Real-World Applications: Where Rigid-Flex Makes Magic

Miniature Cameras & Drones: The flex section can bend 90 degrees to position the camera sensor perfectly without a bulky connector block, allowing for ultra-thin smartphone profiles and compact drone gimbals.

Wearable Health Monitors: ECG and PPG sensors in a smartwatch require reliable contact with your skin. A Rigid-Flex design allows the module to curve slightly, ensuring better contact and comfort, while the rigid part holds the main chip.

Advanced Automotive Sensors: From lidar modules to steering wheel control units, Rigid-Flex PCBs survive the constant vibration, heat, and cold of a car's interior while fitting into awkward, space-constrained locations.

Medical Endoscopes & Implants: For devices that must be incredibly small, sterile, and ultra-reliable, Rigid-Flex is the only choice. It allows for high-density interconnections in a sealed, robust package that can navigate the human body.

Part 5: Considerations for Design: It's Not All Bending and Smiling

Designing with Rigid-Flex is different. It requires a 3D mindset and careful planning:

Cost: The manufacturing process is more complex than for standard PCBs, leading to a higher initial cost. However, this is often offset by the reduced assembly cost, higher yield, and improved reliability in the final product.

Expert Collaboration: Successful Rigid-Flex design requires close collaboration between the electronic designer, the mechanical engineer, and the PCB fabricator from day one. You must design for both electrical performance and mechanical bending.

Bend Radius: The flex areas have a minimum bend radius. Bending them too tightly can damage the copper traces. This must be carefully calculated and designed around.

Conclusion: The Flexible Foundation of Innovation

The trend towards smarter, smaller, and more interconnected devices is unstoppable. As sensors become the eyes and ears of our technology, the need for elegant, reliable, and highly integrated interconnection solutions becomes paramount. Rigid-Flex PCBs are no longer a niche technology; they are a critical enabler of innovation. They simplify the complex, pack incredible functionality into tiny spaces, and provide the durability modern products demand. For any engineer designing the next breakthrough smart sensor module, thinking in three dimensions with Rigid-Flex isn't just an option—it's the strategic key to winning the miniaturization game.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..