Flexible Printed Circuits (FPCs) are the unsung heroes behind bendable screens, foldable phones, and wearable devices. But have you ever wondered why some FPCs can withstand thousands of bends while others crack after just a few? The answer lies in a mix of factors that determine their “bendability.” Let’s take a closer look.

1. Material Matters: The Foundation of Flexibility

The base material of an FPC—usually a polyimide (PI) film—is like its backbone. Thicker PI films offer more rigidity, which is good for stability but bad for frequent bending. On the flip side, thinner films (as thin as 12.5μm) are super flexible but need extra care to avoid tearing. Then there’s the adhesive layer that bonds the copper traces to the PI film. Hard adhesives can make the FPC stiff, while soft, flexible adhesives let it bend smoothly. For example, FPCs in smartwatches, which bend every time you move your wrist, rely on ultra-thin PI films and soft adhesives to survive daily wear.

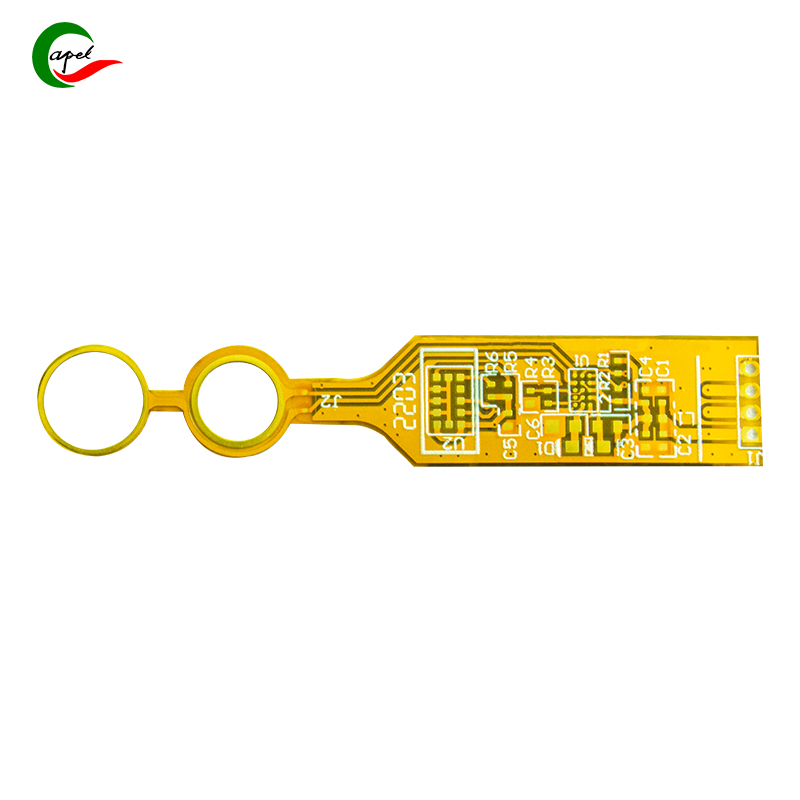

2. Copper Trace Design: The Art of “Bend-Friendly” Layouts

Copper traces carry electricity, but their design can make or break an FPC’s flexibility. Sharp 90-degree angles in traces act like stress points—bend the FPC enough, and these angles will crack first. That’s why engineers use rounded corners or curved traces instead. The width and thickness of the copper also play a role: thick, wide traces are strong but rigid, while thin, narrow ones are more flexible (though they need to be thick enough to avoid breaking under current flow). In foldable phones, where FPCs bend at a tight radius, traces are often laid out in a “serpentine” (snake-like) pattern to spread out stress.

3. Thickness and Layers: Balancing Strength and Bendability

A single-layer FPC is lighter and more flexible than a multi-layer one, which has extra layers of PI and copper. But multi-layer FPCs are necessary for complex circuits in devices like laptops. The key is finding a balance: adding too many layers makes the FPC bulky and hard to bend, while too few might sacrifice durability. For instance, FPCs in fitness trackers (single-layer) bend easily around your wrist, while those in medical devices (multi-layer) need more layers for functionality but still require careful design to stay flexible.

4. Manufacturing Processes: Precision Counts

Even the best materials can fail if manufacturing is sloppy. Over-etching during copper processing can weaken traces, making them prone to breaking when bent. Conversely, under-etching leaves excess copper, adding rigidity. The way the FPC is cut or trimmed matters too—rough edges from poor cutting create stress points. High-quality manufacturers use laser cutting for smooth edges, ensuring the FPC bends evenly without weak spots.

5. Operating Environment: Heat, Moisture, and More

FPCs don’t exist in a vacuum. Extreme heat can make PI films brittle over time, while moisture can seep into adhesives, weakening their bond. Chemicals (like oils from skin in wearables) can also degrade materials. That’s why FPCs in car engines—exposed to high temperatures—use heat-resistant PI films, while those in underwater sensors are coated with waterproof layers to protect flexibility.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.