Not all flexible PCBs are created equal. A high-quality flexible PCB can bend 10,000 times without failing, while a shoddy one might crack after a few uses or short out unexpectedly. Whether you’re sourcing for a project or troubleshooting a design, knowing how to spot the difference is key. Here’s what to check to separate the best from the rest.

The substrate is the "backbone" of a flexible PCB, and its quality is non-negotiable.

- Material Check: High-grade flexible PCBs use polyimide (PI) for durability, especially in applications with heat or frequent bending. Low-quality ones often cut corners with PET, which feels stiffer and cracks more easily. To test, gently bend the PCB—PI should spring back smoothly, while PET might feel rigid or creak.

- Thickness Consistency: A good substrate has uniform thickness (visible under light). Uneven thickness (thicker in some areas, thinner in others) is a red flag—it causes stress points that lead to early failure.

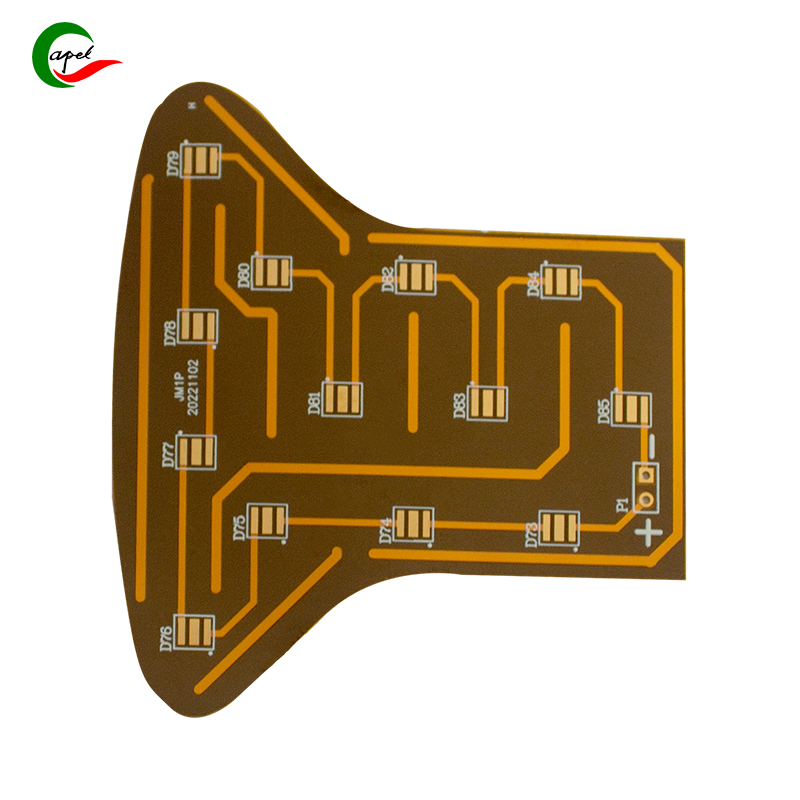

Copper traces carry signals, so their condition directly impacts performance.

- Trace Smoothness: High-quality PCBs have clean, even traces with no jagged edges or thinning. Poorly etched traces (with rough edges or "nicks") are prone to breaking under bending. Use a magnifying glass—if you see gaps or uneven width, it’s a sign of sloppy manufacturing.

- Plating Adhesion: Gold or tin plating (used for corrosion resistance) should bond tightly to copper. Test by gently scraping a non-critical area with a fingernail—flaking or peeling plating means the PCB won’t last in humid or harsh environments.

- Copper Type: Rolled copper (used in high-flex designs) has a matte finish and bends without cracking. Electrodeposited copper (shinier) is cheaper but stiffer—fine for static use, but a bad choice for foldable devices.

Flexible PCBs often have multiple layers, and how well they’re bonded matters.

- No Bubbles or Delamination: Layers (substrate, copper, coverlay) should be fully bonded. Look for bubbles, gaps, or lifting edges—these let moisture seep in, causing shorts. Hold the PCB up to light—any separation between layers is a dealbreaker.

- Coverlay Precision: The protective coverlay (a thin film over traces) should align perfectly with the copper. Misaligned coverlays leave traces exposed to scratches or corrosion. A good coverlay also feels smooth, not tacky—tackiness means cheap adhesive that will fail over time.

The whole point of a flexible PCB is to bend, so put it through its paces (gently, if it’s already in a device).

- Bend Test: Fold the PCB to its rated minimum radius (check the specs) and hold for 30 seconds. A quality PCB will spring back with no visible damage. If it creases, cracks, or the traces turn discolored (a sign of stress), it’s low-grade.

- Vibration Resistance: Tap the PCB lightly—loose components or rattling parts mean poor soldering. In devices like drones or cars, this leads to intermittent connections.

Real-world conditions reveal flaws that visual checks miss.

- Heat Tolerance: High-quality PI substrates handle 200°C+ without warping. A quick test (if safe): hold the PCB near a hair dryer on low heat for 10 seconds. If it curls or smells like burning plastic, it’s using cheap materials.

- Signal Integrity: Use a multimeter to check for continuity after bending. Flickering readings or sudden drops mean weak traces or poor connections—common in low-quality PCBs.

Reputable manufacturers follow industry standards.

- IPC Compliance: IPC-2223 is the global standard for flexible PCBs. A PCB certified to this standard is more likely to meet quality benchmarks.

- Material Certificates: Trustworthy suppliers provide docs proving they use genuine PI, rolled copper, or high-grade adhesives. If a supplier can’t share these, proceed with caution.

A "good" PCB depends on its purpose. A budget PET PCB might work fine for a remote control, but a foldable phone needs PI, rolled copper, and precise bonding. Always match the PCB’s specs to your device’s demands—cutting corners on quality here leads to costly failures later.

In short, quality flexible PCBs are defined by consistency: uniform materials, smooth traces, tight bonding, and reliable performance under stress. By checking these details, you’ll avoid duds and ensure your devices stand the test of time.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.