Date: 2025-07-10

In today’s fast-paced technology era, PCB design plays an important role in ensuring optimal performance and signal integrity. An important aspect of PCB design is controlled impedance, which refers to the ability to maintain precise resistance in a circuit. In this blog, we explore the possibilities of controlled impedance design in PCB circuit boards and how Capel, a trusted industry leader with 15 years of experience, leverages its strong expertise to achieve superior results.

Controlled impedance design is critical for high-speed applications as it ensures the functionality and longevity of electronic devices. Impedance is the resistance a circuit provides to the flow of alternating current (AC). It plays a vital role in matching signal characteristics between components, reducing signal distortion, and ensuring efficient data transmission.

In PCB circuit boards, maintaining controlled impedance is critical to preventing signal degradation due to impedance mismatch. When impedance is not managed correctly, reflections and signal distortion can occur, causing data corruption and ultimately affecting the performance of the entire electronic system.

Signal integrity is especially important in high-speed applications such as data centers, telecommunications and consumer electronics. Failure to achieve controlled impedance can result in reduced data rates, increased error rates, and EMI issues, affecting the overall reliability and quality of the product.

With over 15 years of experience in the circuit board industry, Capel has become a trusted partner for complex PCB design needs. The company’s strong expertise and commitment to delivering exceptional quality have made them experts in controlled impedance design.

Capel’s comprehensive knowledge of industry standards such as IPC-2221, IPC-2141 and IPC-2251 allows them to design PCB circuit boards with special attention to impedance control. They understand the intricacies of transmission lines, dielectric materials, track widths, spacing, and other factors that affect impedance.

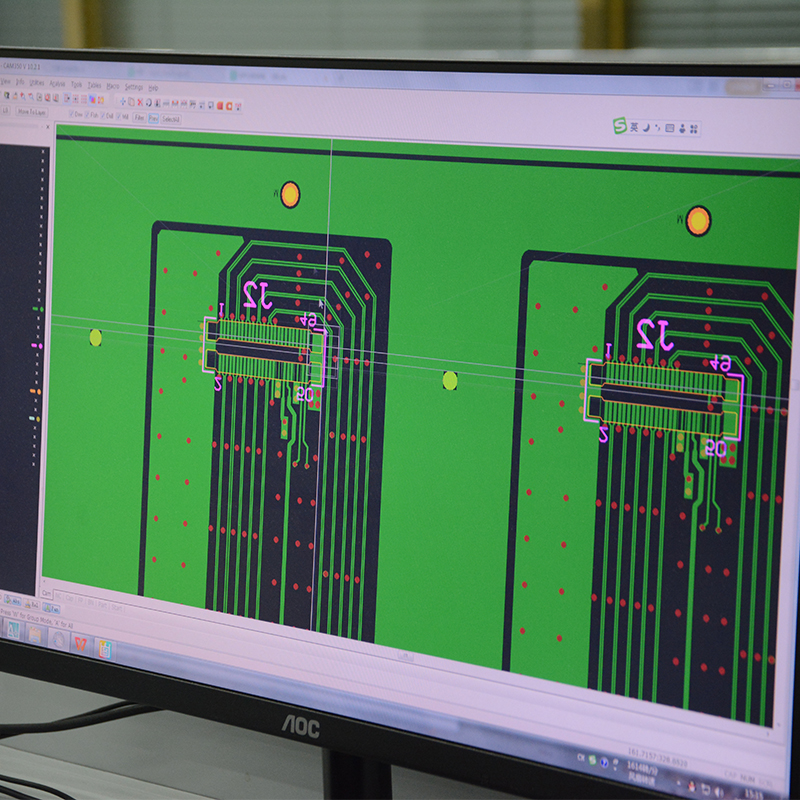

To achieve controlled impedance design, Capel uses advanced software tools to simulate, analyze and optimize PCB layout. By utilizing 3D EM simulation software, signal integrity analysis tools and impedance calculators, Capel ensures that designed PCB boards exhibit consistent impedance characteristics.

Capel’s skilled engineers employ a variety of techniques to effectively control impedance. They carefully design transmission lines, taking into account their length, width, and the dielectric constant of the materials used. In addition, they use differential pairs with matched impedances to reduce crosstalk and ensure accurate signal transmission.

Capel’s stringent quality control measures include in-depth impedance testing throughout the entire production process. They employ high-precision TDR (Time Domain Reflectometry) instruments to verify impedance values and maintain required impedance levels.

By partnering with Capel for controlled impedance design, customers gain several significant benefits:

1. Improved signal integrity: Capel’s expertise ensures signal integrity is maintained, minimizing the risk of signal distortion and data corruption.

2. Optimum performance: Precise impedance control can increase data rates, reduce error rates, and improve the overall performance of electronic devices.

3. Enhanced reliability: By eliminating impedance mismatches and signal reflections, Capel’s design enhances product reliability and reduces the chance of failure or failure.

4. EMI Mitigation: Proper impedance control helps minimize electromagnetic interference (EMI) and enhance EMC (electromagnetic compatibility) compliance.

5. Faster time to market: Leveraging advanced software tools and Capel’s streamlined processes accelerate the time required for PCB design and production, resulting in faster product launches.

Controlled impedance design is a critical aspect of PCB circuit boards to ensure optimal signal integrity and performance. With 15 years of experience and strong expertise, Capel has become the industry’s preferred partner for expertly completing controlled impedance design requirements. By utilizing advanced software tools and meticulous attention to detail, Capel consistently delivers superior quality PCB boards that meet the most demanding impedance control specifications. Trust Capel to leverage their expertise to lead your electronic system to success through superior controlled impedance design.

Capel manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..