Date: 2025-12-11

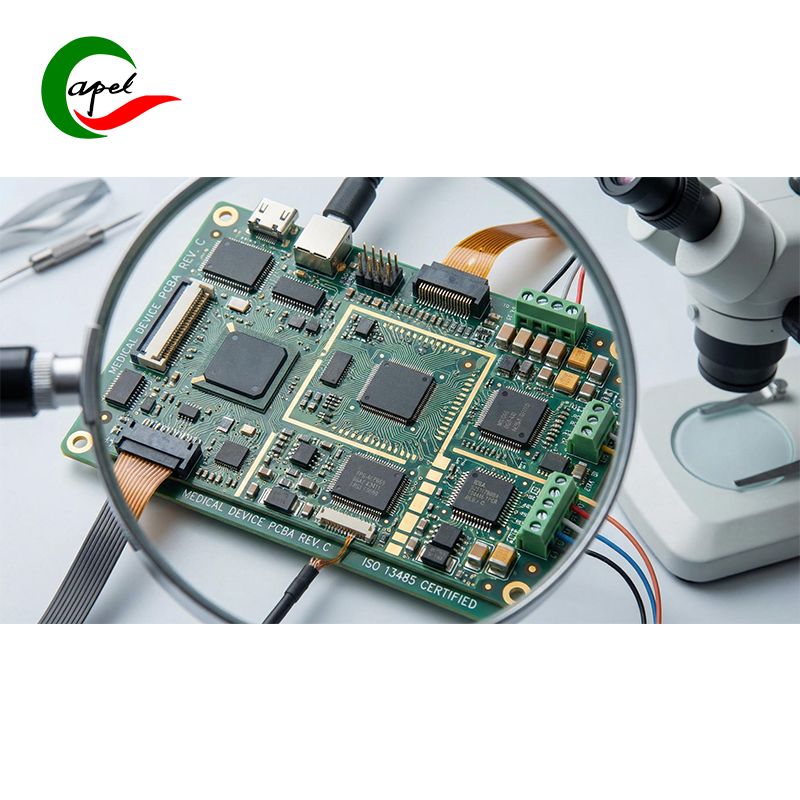

Let's be honest: most people never think about the tiny, green (or sometimes not so green) electronic boards hidden inside their gadgets. But what if I told you that some of these boards are beating inside a person's chest, generating images that determine a surgeon's next move, or silently tracking critical health data on your wrist? Welcome to the world of medical-grade PCBA – where "reliability" isn't a feature, it's the only non-negotiable standard.

Here at Kaboer, we've been in the precision electronics manufacturing game for years. Today, let's cut through the noise and talk deeply about the "electronic heart" inside medical devices – Medical PCBA – and why choosing its manufacturer is a decision far more critical than you might think.

First off, don't confuse it with the motherboard in your laptop or the board in your smartphone.

PCBA stands for Printed Circuit Board Assembly. It's the complete, functional module you get after all those microscopic resistors, capacitors, chips, and connectors are precisely placed and soldered onto a bare PCB (Printed Circuit Board). Think of it as a complete "miniature electronic system," ready to power up.

The prefix "medical-grade" is what changes everything. It signifies a fundamental shift in philosophy:

Different Design Standards: Component selection prioritizes long-term stability and, if needed, biocompatibility from the very first resistor.

Different Manufacturing Environment: Production often occurs in cleanrooms where a single speck of dust is considered a contaminant.

Different Testing Rigor: Boards undergo brutal aging, thermal cycling, and vibration tests that would make commercial electronics weep.

Different Documentation & Traceability: Every material batch, every process parameter is meticulously documented and must be traceable for years.

In short, commercial PCBA seeks "value" and "functionality." Medical PCBA is built on the creed of "failure is not an option."

Its presence is ubiquitous in modern healthcare, operating across several critical fronts:

1. Life Support & Implantable Core (Highest Risk)

These devices intervene directly in vital physiological processes.

Implantable Devices: Pacemakers, Implantable Cardioverter Defibrillators (ICDs), cochlear implants, neurostimulators. Their PCBA must function flawlessly for a decade or more inside the harsh environment of the human body, with extreme low power consumption and absolute reliability. An ICD's PCBA, for instance, must correctly identify a lethal heart rhythm and deliver a life-saving shock within milliseconds.

Life-Sustaining Equipment: Ventilators, dialysis machines, ECMO. Their main controller PCBA must operate 24/7, managing gas flows, fluid rates, and pressures with precise, real-time control. Any malfunction can directly interrupt life support.

2. The Eyes of Diagnosis (High Performance & Stability)

Modern diagnostics rely on clear images and accurate data.

Medical Imaging: CT, MRI, Ultrasound, X-ray systems. The PCBA in these machines processes extremely faint signals or high-frequency energy, requiring superior signal integrity and noise immunity. A faulty image processing board can lead to a misdiagnosis.

In-Vitro Diagnostics (IVD): Blood analyzers, biochemical analyzers, DNA sequencers. These perform precise fluidic control and optical measurements, where the accuracy of the PCBA dictates the accuracy of the test result.

3. Continuous Monitoring & Daily Health (High-Reliability Requirements)

This is the category closest to everyday life.

Patient Monitors: Found in hospital rooms and ICUs, tracking ECG, blood pressure, SpO2, etc.. The PCBA must ensure continuous, accurate data streams and timely alarms.

Portable/Home-Use Devices: Glucose meters, digital blood pressure monitors, portable ECG devices, hearing aids. Their PCBA needs to be durable and accurate in unpredictable home environments (humidity, occasional drops).

4. Rehabilitation & Therapeutic Equipment

Examples include physiotherapy equipment, infusion pumps, and surgical robots. For an infusion pump, the control PCBA must precisely drive a motor to deliver medication at a set rate and volume with minimal error.

Choosing a medical PCBA partner isn't about price and lead time alone. Below the surface lies an iceberg of compliance and quality mandates. Here are the real deal-breakers:

1. Regulatory & Standards Compliance (The Gatekeepers)

Quality Management System: ISO 13485 is the gold standard for medical device quality systems. Unlike generic ISO 9001, it emphasizes risk management and full-process traceability. This is non-negotiable for a manufacturer.

Product Safety & Environmental: Compliance with RoHS, REACH, and other regulations is mandatory for material safety.

Market Access: For the US market, FDA regulations apply. For the European Union, the Medical Device Regulation (MDR) is key.

2. Specialized Processes & Materials

High-Reliability Soldering: Use of medical-grade solder and adherence to stricter soldering standards (like higher classes of IPC-A-610) ensures joints won't fail under thermal stress or over time.

Conformal Coating: To protect against cleaning fluids, moisture, or contaminants, a specialized protective coating is often applied to the assembled PCBA.

Specialized Substrates: For implantable or wearables, Flexible PCBs (FPC) or rigid-flex boards may be used. For high-power devices, metal-core boards (like aluminum) aid heat dissipation.

3. Uncompromising Quality Control & Traceability

Full Traceability: Requires two-way traceability for every component batch, PCB laminate, production lot, and test result. Any field issue must be quickly isolated.

100% Testing: The concept of "sampling" is almost non-existent. Electrical testing (e.g., flying probe), functional testing, and burn-in are typically performed on 100% of units.

Cleanliness Control: Assembly areas control particulate contamination to prevent long-term reliability issues.

At Kaboer, we understand the weight of responsibility that comes with medical electronics. We aim to be more than a vendor; we are a partner in safeguarding your product's compliance, reliability, and time-to-market.

1. Rooted in Systematic, Compliant Manufacturing

Our factory management system is built on the foundation of ISO 13485. This certificate represents our operational DNA—a fully documented system encompassing design review, supplier management, production control, and packaging, ensuring every build is auditable and traceable.

2. Expertise in High-Reliability Electronics Assembly

Precision Manufacturing Experience: We have extensive experience with High-Density Interconnect (HDI) boards and Flexible Printed Circuits (FPC), crucial for today's miniaturized, advanced medical devices.

Comprehensive Process Coverage: From standard SMT to specialized packaging for implantables, we have the technical portfolio and validation protocols.

Stringent Quality Control: Multiple checkpoints—Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (OQC)—are standard. We commit to 100% electrical testing for medical projects, ensuring every delivered PCBA meets your specifications.

3. Committed to Being Your Seamless Extension from R&D to Mass Production

Design for Excellence (DFX) Services: We engage early in the design phase, offering feedback on Manufacturability (DFM), Testability (DFT), and Reliability (DFR). This helps optimize your design, avoid costly late-stage changes, and accelerate time-to-market.

From Rapid Prototyping to Volume Production: We support collaborations starting with "one-piece" prototyping, allowing for low-cost, fast design verification. Once proven, we seamlessly transition to consistent, high-volume manufacturing.

Supply Chain Resilience: Leveraging our industry network, we help manage supply chain risks for critical components, providing alternatives to keep your production on schedule.

In the medical field, choosing a PCBA partner is a commitment that binds technology, trust, and responsibility. It impacts your product's reputation and, ultimately, patient well-being.

At Kaboer, we respect that trust. We believe our value lies not in being the cheapest, but in being the most reliable partner, helping your innovative medical devices serve life safely and dependably.

If you're developing the next generation of patient monitors or pioneering a novel implantable device, let's talk. Let's combine our expertise to build technology that truly makes a difference.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..