Date: 2025-07-16

In today’s world, where miniaturization and flexibility are becoming important factors in electronic design, the need for efficient prototyping of flexible printed circuit boards (PCBs) with impedance-controlled traces has grown significantly. As electronic devices continue to evolve, designers are keen to find innovative and cost-effective ways to prototype such PCBs. In this blog, we’ll take a deep dive into the process of prototyping flexible PCBs with impedance-controlled traces, exploring the challenges, available options, and best practices.

Before delving into the details of flexible PCB prototyping with impedance controlled traces, it is important to understand the concepts and benefits of flexible PCBs. Flexible PCBs, also known as flex circuits, are designed to be bent, folded, or twisted to save space and increase flexibility in a variety of applications. Their lightweight nature, robustness and ability to adapt to non-planar surfaces make them ideal for industries such as automotive, medical and aerospace.

Impedance control is critical when designing high frequency circuits as it ensures signal integrity and minimizes electromagnetic interference. In flexible PCBs, maintaining impedance control is even more important because they are inherently susceptible to signal loss and distortion caused by bending or flexing. Prototyping with impedance-controlled traces can help avoid such issues, resulting in a reliable and robust flex PCB solution.

When prototyping flexible PCBs with impedance-controlled traces, designers have several options to consider. Let’s explore some commonly used methods:

A. Printed Circuit Board (PCB) Prototyping Company:

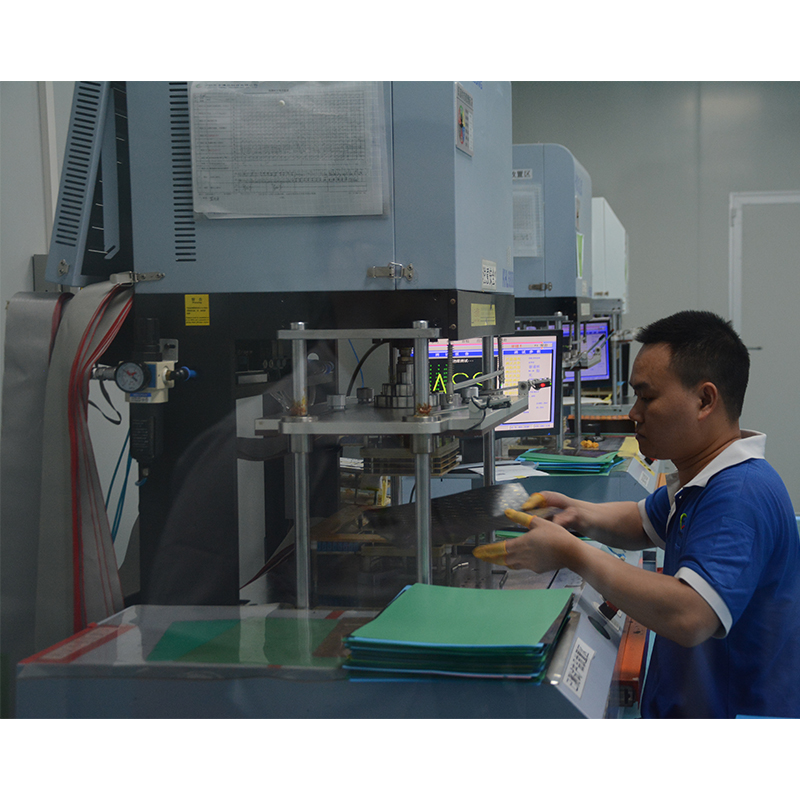

Working with a professional PCB prototyping company is one way to efficiently prototype flexible PCBs with impedance-controlled traces. These specialist companies have the expertise, tools and experience to handle the complexities associated with flexible circuits. By providing the necessary design files and specifications, designers can obtain high-quality prototypes with the required impedance control.

b. Internal prototyping:

Designers who prefer more control over the prototyping process can choose to prototype flexible PCBs in-house. This method requires investing in appropriate equipment, such as a flexible PCB printer or plotter. Software tools that simulate and analyze impedance control, such as Altium Designer or Eagle, can help achieve the desired trace impedance during the prototyping process.

To ensure successful design of flexible PCB prototypes with impedance controlled traces, best practices must be followed. Here are some guidelines:

a. Comprehensive design preparation:

Before beginning the prototyping process, designers should fully prepare their designs, including layer stackup, trace widths, and spacing to achieve the desired impedance control. It can be helpful to utilize design software that supports impedance calculation and simulation.

b. Material selection:

For flexible PCB prototypes with impedance-controlled traces, choosing the right material is critical. Choosing a flexible substrate such as polyimide with low signal loss and stable dielectric properties can significantly enhance signal transmission and overall signal integrity.

c. Validation and testing:

After the prototyping stage, it is critical to verify performance and test impedance control. Accurately measure impedance discontinuities along traces using test equipment such as time domain reflectometry (TDR).

Prototyping flex PCBs using impedance controlled traces is not without its challenges, but with the right knowledge, tools, and methods, designers can successfully bring their innovative flex PCB designs to reality. Whether working with a PCB prototyping company or exploring in-house prototyping options, understanding the importance of impedance control and following best practices will pave the way for reliable, flexible solutions that meet the needs of today’s dynamic electronics industry. So go ahead and start your journey of prototyping flexible PCBs with impedance controlled traces and unlock endless possibilities for your next electronic design endeavor.

Capel manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..