Date: 2025-07-10

Introduction As a circuit board engineer working in the ECU (Engine Control Unit) industry, I understand the critical role PCB (Printed Circuit Board) solutions play in ensuring optimal vehicle control. The integration of advanced technologies, stringent performance requirements, and reliability needs have made the development of reliable ECU PCB solutions a critical aspect of the automotive industry. In this article, we will analyze the challenges and opportunities of creating reliable ECU PCB solutions for optimal vehicle control, and explore the technological advancements and best practices that are driving innovation in this field.

The Importance of Vehicle Engine Control Units PCBs in Vehicle Control The engine control unit (ECU) serves as the brains of modern vehicles, managing and controlling numerous systems including engine performance, fuel injection, emissions control and overall vehicle operation. PCB is the basic platform for integrating complex electronic components and provides the necessary connections for seamless communication between these components. The reliability and functionality of the ECU PCB directly affects the overall performance, efficiency and safety of the vehicle. Therefore, developing reliable ECU PCB solutions is crucial to ensure optimal vehicle control and enhance the overall driving experience.

Challenges in Ecu Circuit Board Development The development of ECU PCB solutions faces significant challenges due to the harsh operating environment of automotive applications. Factors such as temperature changes, vibration, electrical noise, and stringent regulatory standards require robust design and manufacturing practices. In addition, the increasing complexity of vehicle control systems and the need for real-time processing require advanced, high-performance PCB solutions. Meeting these challenges is imperative to provide reliable ECU PCBs that can withstand harsh automotive environments while ensuring precise and efficient vehicle control.

Technological Advances in ECU PCB board Solutions To meet the ever-changing needs of the automotive industry, technological advancements have significantly changed the design and manufacturing of ECU PCB solutions. Using advanced materials such as high-temperature laminates, specialized substrates, and advanced copper alloys, PCBs can be developed that can withstand extreme temperatures and harsh operating conditions. In addition, the use of surface mount technology (SMT) components, fine-pitch components, and integrated passive devices (IPD) enhances ECU PCB miniaturization and performance, enabling compact and efficient designs necessary for modern vehicle control systems.

In addition, the combination of advanced manufacturing technologies such as HDI (High Density Interconnect) and microvia technology has facilitated the development of multi-layer PCBs that enhance signal integrity, reduce electromagnetic interference, and improve thermal management. These technological advancements not only improve the reliability and performance of ECU PCB solutions, but also enable the integration of complex control algorithms, sensor interfaces and communication protocols necessary for modern vehicle control applications.

Best Practices for Reliable ECU PCB Solutions Creating reliable ECU PCB solutions requires applying best practices throughout the design, manufacturing and testing phases. Collaboration between circuit board engineers, automotive OEMs and semiconductor suppliers is critical to ensuring that ECU PCB designs meet performance, reliability and manufacturability requirements. Design for Manufacturability (DFM) and Design for Reliability (DFR) principles play a vital role in optimizing the design and layout of ECU PCBs to minimize potential failure points and ensure consistent manufacturing yields.

Incorporating advanced simulation and modeling techniques such as thermal analysis, signal integrity analysis, and transient voltage analysis enables board engineers to evaluate the performance and reliability of ECU PCB designs under a variety of operating conditions. In addition, utilizing advanced testing methods, including environmental stress testing, accelerated life testing, and in-circuit testing, is critical to verify the robustness and longevity of ECU PCB solutions before integrating them into automotive systems.

Case Study: Optimizing Vehicle Control with Reliable ECU PCB Solutions To illustrate the impact of reliable ECU PCB solutions on vehicle control, we can analyze a case where the implementation of advanced PCB technology and design optimization resulted in significant vehicle performance and reliability improve. In this example, a leading automotive OEM partnered with a specialist circuit board engineering company Capel to develop next-generation ECU PCB solutions for its high-performance vehicles. The main objectives of the project are to improve the precision and responsiveness of engine control, optimize fuel efficiency and ensure consistent performance under extreme operating conditions.

Through collaborative design iterations and thorough simulation, the Capel’s engineering team optimized the ECU PCB layout to minimize signal attenuation, reduce electromagnetic interference, and enhance heat dissipation. The integration of high-density interconnects and advanced materials enables the development of compact and rugged PCB solutions capable of housing the complex electronic components and interfaces required for advanced vehicle control algorithms. Rigorous environmental testing, including thermal cycling, vibration testing and electromagnetic compatibility (EMC) testing, validates the ECU PCB’s reliability and durability under actual operating conditions.

When integrated into a vehicle, the optimized ECU PCB solution demonstrates significant improvements in engine performance, throttle response and overall drivability. Advanced control algorithms driven by reliable PCB solutions improve fuel efficiency and reduce emissions, meeting OEM sustainability and regulatory compliance goals. In addition, the robustness of the ECU PCB solution ensures consistent performance in different driving scenarios ranging from urban traffic conditions to high-speed highway cruising, bringing an excellent driving experience to end users.

Future Trends and Innovations in ECU PCB Solutions Looking ahead, the future of ECU PCB solutions will undoubtedly be shaped by continued technological innovation and the industry’s shift towards electrification, connectivity and autonomous driving. The integration of AI (artificial intelligence), machine learning and advanced sensor technologies into vehicle control systems will drive demand for ECU PCB solutions with enhanced processing power, low latency and higher data throughput. In addition, the popularity of electric vehicles and the electrification of powertrain systems will require the development of ECU PCB solutions suitable for high-voltage applications and stringent safety requirements.

The convergence of vehicle-to-everything (V2X) communications, telematics and advanced driver assistance systems (ADAS) will further drive the development of ECU PCB solutions, requiring seamless integration of wireless connectivity, sensor fusion and real-time data processing capabilities. Therefore, circuit board engineers will work with automotive industry stakeholders to continue to utilize advanced design methods, materials and manufacturing processes to develop reliable ECU PCB solutions to support the next generation of smart and efficient vehicle control systems.

Conclusion In conclusion, developing reliable ECU PCB solutions is critical to achieve optimal vehicle control, improve vehicle performance, and ensure the safety and satisfaction of automotive consumers. Circuit board engineers play a key role in addressing challenges associated with ECU PCB development through the application of advanced technologies, best practices, and partnerships with automotive OEMs and semiconductor suppliers. By embracing technological advancements, incorporating best practices, and keeping up with future trends, circuit board engineers can continue to drive innovation and deliver reliable ECU PCB solutions that help shape the future of vehicle control and mobility.

By embracing technological advancements, incorporating best practices, and keeping up with future trends, circuit board engineers can continue to drive innovation and deliver reliable ECU PCB solutions that help shape the future of vehicle control and mobility.

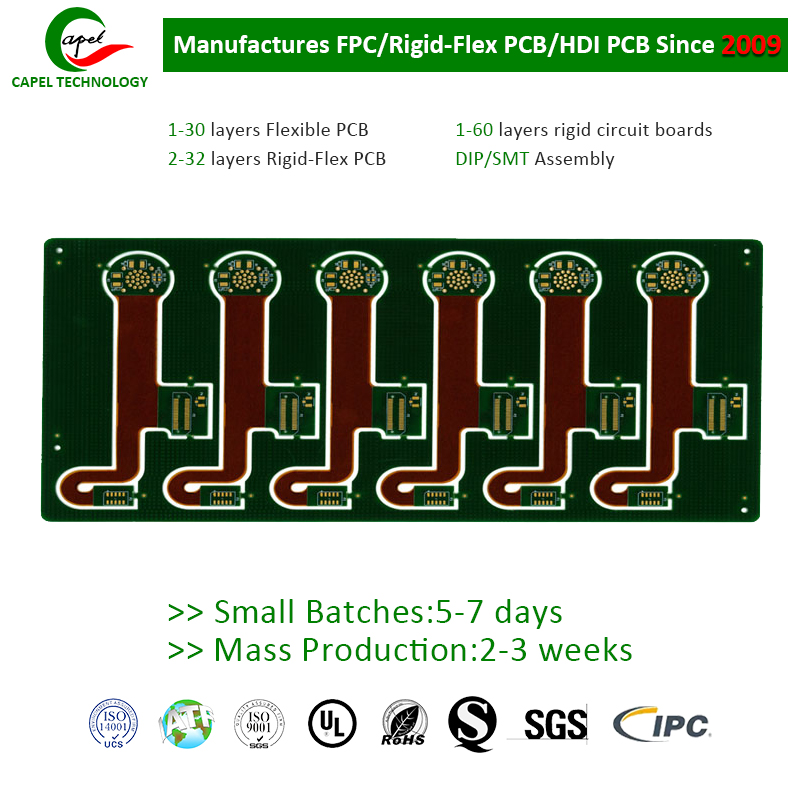

Capel manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..