Date: 2025-07-17

In today’s technologically advanced world, the demand for flexible electronics continues to grow. Flexible electronic devices have the ability to bend, fold, and stretch, providing a wide range of possibilities for innovation in various industries. However, the design and manufacture of these devices faces many challenges, especially when it comes to the complex circuitry they require. This is where rigid-flex circuit boards come into play. But are rigid-flex circuit boards really suitable for flexible electronics? Let’s explore this interesting topic in detail.

Flexible electronics, as the name suggests, are electronic devices that can be bent, twisted or stretched without damage. These devices are made possible by incorporating flexible materials such as plastic or polyimide into their structure. This flexibility allows for seamless integration into a variety of applications, from wearable technology to biomedical devices and even foldable smartphones.

For flexible electronic devices to operate efficiently, they require reliable and robust circuit systems to accommodate their flexible properties. This is where rigid-flex circuit boards come into play. Rigid-flex circuit boards are a hybrid of traditional rigid PCBs (Printed Circuit Boards) and flexible circuits. They provide the necessary combination of rigidity and flexibility required for successful operation of flexible electronic devices.

The construction of rigid-flex circuit boards involves integrating rigid and flexible materials on the same board. This not only simplifies the overall manufacturing process, but also ensures the reliability and durability of the circuit system. The rigid portion of the board holds the components, while the flexible portion allows for necessary bending and stretching without compromising the integrity of the electrical connections.

Several factors come into play when considering the suitability of rigid-flex circuit boards for flexible electronics. First, these boards offer a compact and lightweight solution. Since no additional connectors and cables are required, valuable space within the device is saved and the overall weight is reduced. This is especially important in applications such as wearable technology, where size and weight play an important role in user comfort.

In addition, rigid-flex circuit boards offer excellent signal integrity and electrical performance. The integration of rigid and flexible materials ensures that electrical connections remain intact even if the circuit board is bent or stretched. This is crucial for the proper operation of flexible electronic devices. Reliable transmission of signals and data is critical, especially in precision-critical applications such as medical equipment.

Another important aspect to consider is the cost-effectiveness of using rigid-flex circuit boards in the manufacturing process. While the initial cost of these boards may be higher compared to traditional rigid PCBs, the long-term benefits outweigh the investment. Rigid-flex circuit boards reduce the need for additional components, simplify the assembly process, and reduce the possibility of failure due to loose connections or broken wires. This reduces production costs and increases the overall reliability of the product.

Additionally, the design flexibility provided by rigid-flex circuit boards is critical for developing innovative and unique flexible electronic devices. They allow complex circuit patterns, allowing engineers and designers to fully explore the potential of flexible electronics. This versatility opens up new possibilities for creative designs and shapes, ultimately benefiting various industries seeking to incorporate flexible electronics into their products.

However, it’s worth noting that rigid-flex circuit boards are not a one-size-fits-all solution. The suitability of these boards depends on the specific application and intended use of the flexible electronic device. Factors such as the level of flexibility required, the complexity of the circuit and the operating environment must be carefully considered during the design phase.

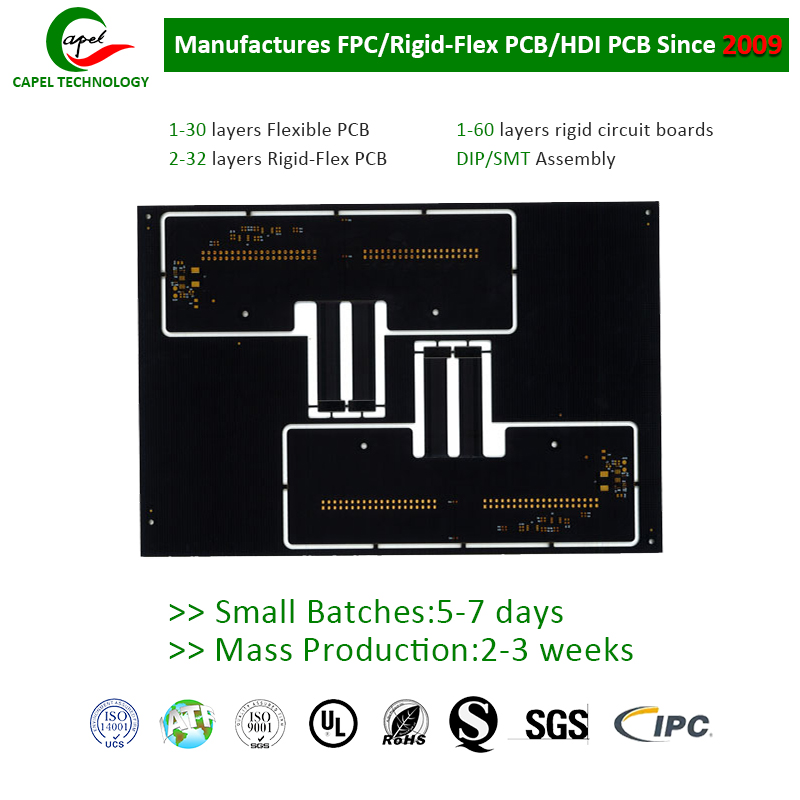

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..