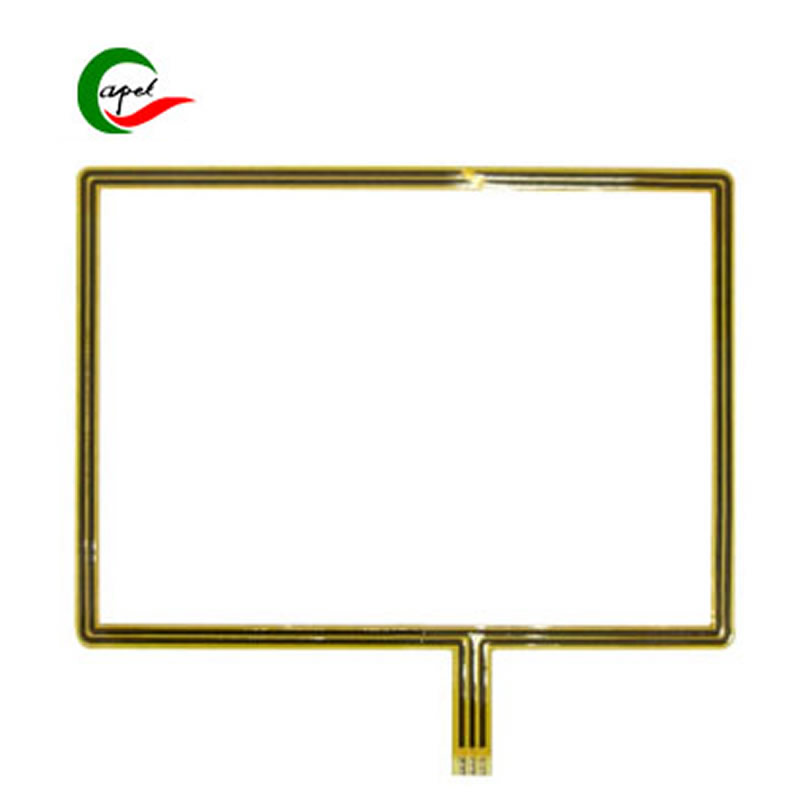

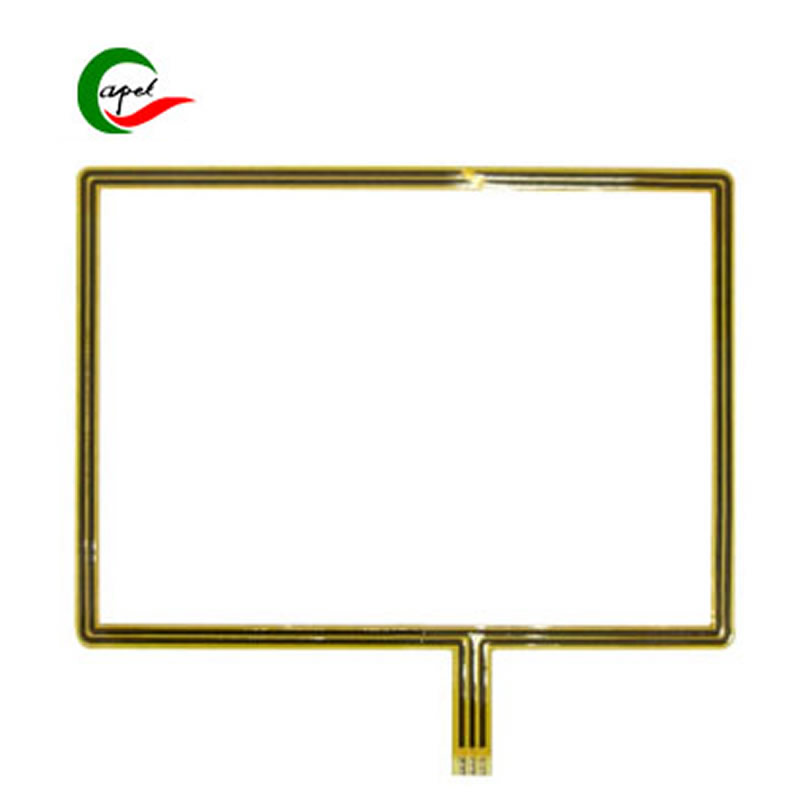

POS Antenna FPC

A short introduction:

Type: POS Antenna FPC

Minimum Line Width/Line Spacing: 0.1mm/0.2mm

Number of Layers: 2 Layers

Thickness: 0.20mm

Surface Finish: Immersion Gold 1 micro inch

Kaboer's Services:

Support Customized 1-30 Layer FPC Flexible PCB, 2-32 Layers Rigid-Flexible Circuit Boards, 1-60 Layers Rigid PCB, Reliable Fast Turnaround PCBs Prototyping, Rapid SMT PCB Assembly

Industries We Serve:

Medical Devices, IoT, TUT, Drones, Aerospace, Automotive, Telecom, Consumer Electronics, Military, Aerospace, Industrial Controls, Artificial Intelligence, Electric Vehicles, etc. ......

If you have related needs, please feel free to click the button below to send us an email.

Type: Flexible Printed Circuit (FPC) for POS antenna, specially designed for POS wireless communication, with excellent flexible bending performance. Whether it is the built-in antenna layout of handheld mobile POS machines or the integration of multiple antennas in desktop POS terminals, it can be flexibly adapted to the compact space inside the equipment (e.g., the edge of the body, the battery compartment periphery) to realize the efficient transmission of multi-frequency band signals, replacing the traditional rigid antenna wiring and enhancing the stability of the equipment's communication.

Minimum line width / line spacing: 0.1mm/0.2mm high precision standard. This parameter is optimized for the multi-band signal characteristics of POS: 0.1mm line width ensures lower transmission loss of high-frequency signals (e.g. Bluetooth 5.0, NFC 13.56MHz), 0.2mm line spacing reserves space for parallel wiring of multiple antennas, supports the independent transmission of 4G and Bluetooth signals, avoids inter-band interference, and ensures real-time uploading of transaction data without delay.

Layers: 2-layer structure design, through scientific layering to achieve fine signal management:

Signal Layer: Differential routing design, optimize 4G LTE signal impedance matching (target impedance 50Ω±10%), reduce signal reflection;

Grounding Layer: Large copper foil coverage, forming a stable reference plane, enhance the antenna radiation efficiency, and at the same time, shield the POS internal battery, motherboard and other components of the electromagnetic interference to ensure the purity of the signal. Ensure signal purity.

Two-layer synergy significantly reduces the risk of multi-band signal crosstalk, especially suitable for POS devices that support “wireless payment + data upload” dual-mode function.

Thickness: 0.20mm thin and light, perfectly adapted to the needs of POS machine compact structure. Under the trend of “thin and light” design of handheld POS devices (e.g. body thickness <15mm), it can significantly reduce the space occupied by the antenna module, freeing up space for core components such as the battery and touch screen, and at the same time, improve the flexibility of bending the wiring when assembling the device and reduce production loss.

Surface treatment: the use of immersed gold 1 micro-inch process, through precise control of nickel-gold plating thickness (nickel layer ≥ 3μm, gold layer ≥ 0.025μm), to bring multiple advantages:

excellent conductivity of the gold layer, reducing high-frequency signal transmission loss (especially in the NFC near-field communication, to enhance the signal sensing sensitivity);

1 micro-inch precision gold layer thickness balance between corrosion resistance and cost, to adapt to the POS machine long-term use of daily wear and tear, perspiration erosion (particularly in NFC near-field communications, enhance signal sensitivity); 1 micro-inch precision gold layer thickness balance of corrosion resistance and cost, to adapt to POS machine long-term use of the Daily wear and tear, sweat erosion (handheld scenarios) and other environmental factors;

Enhance the reliability of the solder joints to ensure stable contact between the wires and the antenna module, the motherboard, and the soldered parts of the antenna module, to reduce the communication disconnection problems caused by poor contact.

Kaboer Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type |

Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number |

1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size |

Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness |

FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish |

Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um |

Impedance Controlled Tolerance |

±10% |

|

Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm |

Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..