Date: 2025-12-18

When you think of a circuit board, you probably picture the standard green, rigid FR-4 board. But for applications where heat is the enemy of performance and reliability, a standard board can quickly become a bottleneck. This is where the aluminum circuit board (also called a Metal Core PCB or MCPCB) comes into play—a specialized solution designed to manage heat like no ordinary board can.

For engineers designing high-power LEDs, power converters, automotive systems, or any device that generates significant heat, understanding aluminum PCBs is key to unlocking better performance and longer product life.

An aluminum circuit board is a type of printed circuit board that uses an aluminum alloy base layer instead of the traditional fiberglass (FR-4) or epoxy resin.

Its structure is typically a three-layer sandwich:

Circuit Layer (Copper): The top layer, where the copper traces are etched to form the electrical circuits, just like a standard PCB.

Dielectric Layer (Insulating): A thin, thermally conductive but electrically insulating layer. This is the critical component—it must efficiently transfer heat from the copper to the aluminum while preventing electrical shorts.

Base Layer (Aluminum): A thick plate of aluminum alloy (usually 5052 or 6061). This acts as a massive, built-in heat sink, drawing heat away from components and dissipating it.

Think of it like this: a standard FR-4 board is like a workbench with a thin wooden top. An aluminum PCB is like that same workbench, but with the wooden top bonded directly to a thick, cold metal plate that actively pulls heat away from anything hot placed on it.

The primary and overwhelming purpose of an aluminum PCB is heat dissipation. This single advantage solves a host of critical problems in electronics design.

How it Works & Why It Matters:

In high-power applications, components like LED chips, power transistors, and motor drivers generate substantial heat. On a standard board, this heat gets trapped locally, causing:

Premature Failure: Heat drastically shortens the lifespan of electronic components.

Performance Degradation: Many components, like LEDs, become dimmer and less efficient as they overheat.

Unreliable Operation: Overheating can lead to thermal runaway or erratic circuit behavior.

An aluminum substrate solves this by conducting heat away from the hot spots laterally across the board and then dissipating it through its entire metal core. This allows components to run cooler, closer to their ideal operating temperatures, which directly translates to:

Higher maximum power output

Longer operational lifespan

Greater design compactness (by reducing the need for bulky external heat sinks)

Improved overall system reliability

You'll find aluminum circuit boards wherever efficient heat management is non-negotiable:

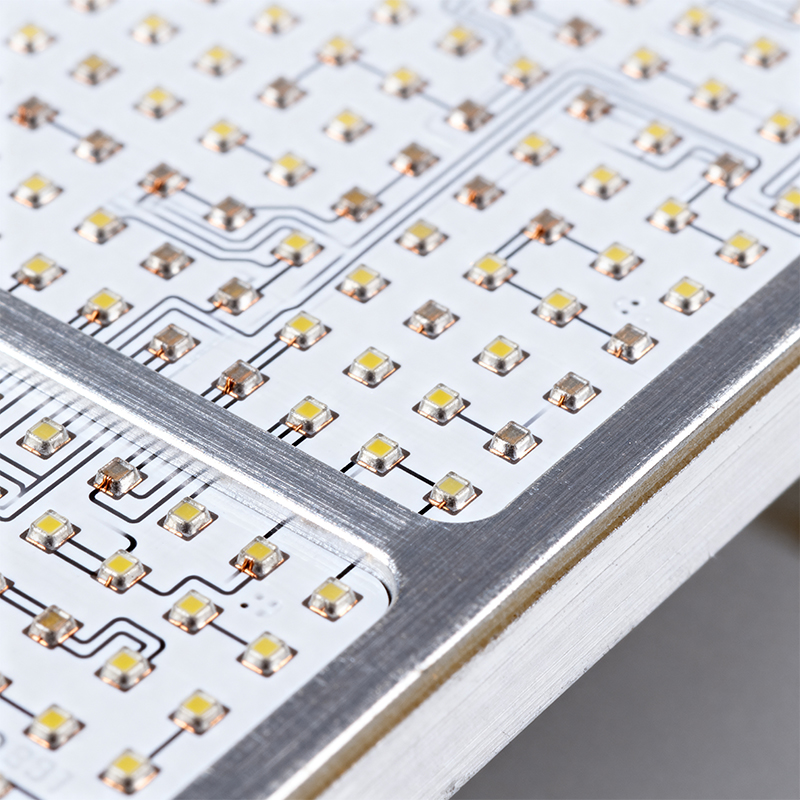

LED Lighting: This is the most common application. High-brightness LED arrays for street lights, stadium lighting, automotive headlights, and grow lights all rely on aluminum PCBs to manage the intense heat.

Power Supplies & Converters: Switching regulators, DC/DC converters, and motor controllers use power semiconductors that generate significant heat.

Automotive Electronics: Components in tight, hot engine compartments (e.g., headlight drivers, power steering controls) benefit from the ruggedness and cooling of aluminum boards.

Radio Frequency & High-Power Applications: RF amplifiers and transmission equipment.

While powerful, aluminum PCBs have specific trade-offs:

Higher Cost: The materials and specialized manufacturing process make them more expensive than standard FR-4.

Limited Layer Count: They are typically single or double-sided. Creating complex, multi-layer boards with an aluminum core is challenging and costly.

Specialized Assembly: The different thermal mass requires careful adjustment of SMT reflow soldering profiles to ensure good solder joints without damaging the board.

Electrical Insulation Reliance: The entire design's success hinges on the integrity of the thin dielectric layer. Any defect can lead to a short circuit to the metal base.

Working with materials like aluminum requires a manufacturer that understands more than just standard FR-4 processes. At Kaboer, our experience extends to these specialized substrates. We recognize that successfully assembling an aluminum PCB means carefully managing the thermal dynamics during soldering and ensuring the design leverages the metal core's properties effectively.

For projects where heat is the primary design constraint, the choice of substrate is as important as the choice of components. Partnering with a manufacturer experienced in the nuances of aluminum and other metal-core boards can be the difference between a product that struggles and one that performs reliably for years.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..