In the age of electric vehicles (EVs), autonomous driving, and smart cabins, cars are no longer just mechanical machines—they’re rolling tech platforms. At the heart of this transformation lies a humble yet powerful component: the automotive flexible printed circuit (FPC). These thin, bendable circuits are the "nervous system" that connects sensors, screens, batteries, and brains in modern vehicles, enabling everything from adaptive cruise control to in-car entertainment. Let’s explore why automotive FPCs have become irreplaceable in today’s car manufacturing.

For decades, cars relied on bulky wire harnesses—bundles of thick, rigid cables—to transmit power and signals. But as vehicles pack in more technology (a single EV can have over 100 sensors), wire harnesses hit critical limits:

- Weight and space: A luxury car’s wire harness can weigh 50+ pounds and snake through every nook, consuming valuable space needed for batteries or passenger comfort. FPCs, by contrast, are 70% lighter and 90% thinner, fitting into tight gaps between panels or around curves.

- Reliability: Vibrations from rough roads or engine movement can loosen wire connections over time, causing malfunctions. FPCs, with their seamless, one-piece design, resist vibration fatigue—critical for components like EV battery management systems (BMS) that operate nonstop.

- Complexity: Modern cars require high-speed data transmission (e.g., 10Gbps for LiDAR or 5G V2X). Wire harnesses suffer from signal interference, while FPCs with shielded layers and controlled impedance ensure clean, fast data flow.

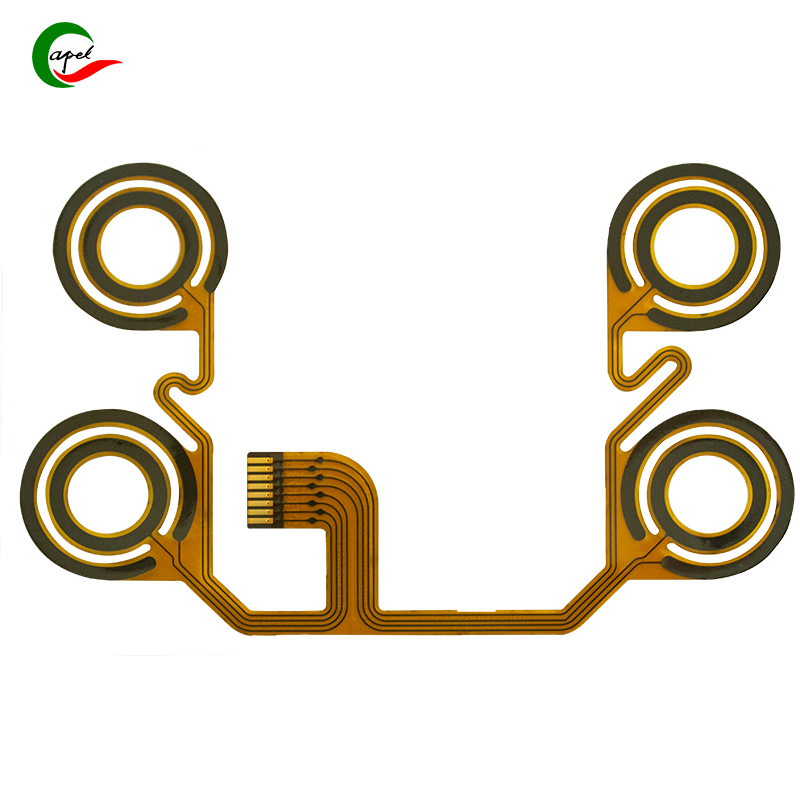

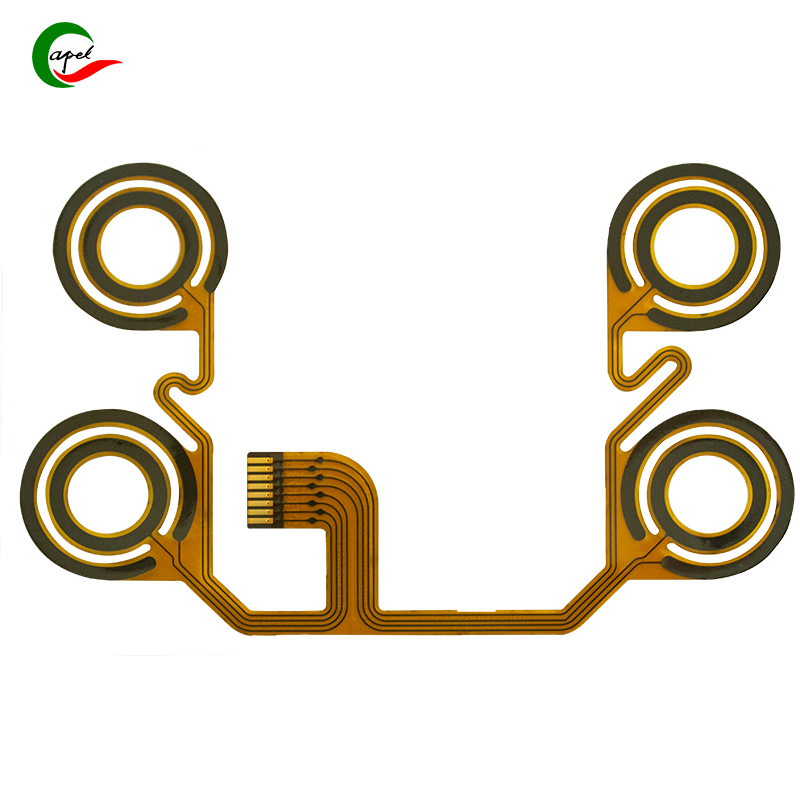

Automotive FPCs aren’t one-size-fits-all—they’re engineered for specific roles, each demanding extreme durability and precision.

EV batteries are marvels of engineering, with thousands of cells working in harmony. FPCs are the unsung heroes that keep them in check:

- Cell monitoring: Ultra-thin FPCs (as thin as 0.1mm) snake between battery cells, measuring voltage, temperature, and charge levels in real time. This data prevents overcharging, overheating, or cell imbalance—risks that could lead to fires.

- Space efficiency: EV batteries are packed tightly to maximize range. FPCs’ flexibility lets them conform to the battery’s shape, avoiding the bulk of rigid PCBs that would reduce energy storage.

- Heat resistance: Under the hood or in battery packs, temperatures can hit 125°C. Automotive FPCs use high-grade polyimide (PI) substrates and flame-retardant adhesives to survive these extremes.

Self-driving features like lane-keeping, automatic emergency braking, and 360° cameras depend on FPCs to relay critical data:

- Sensor connectivity: LiDAR, radar, and cameras mounted around the car generate massive amounts of data. FPCs with high-frequency performance (using low-loss materials like LCP) transmit this data to the ADAS controller without lag—critical for split-second decisions.

- Durability in harsh environments: Cameras behind windshields face temperature swings from -40°C to 85°C; radar sensors near bumpers endure mud, water, and vibration. FPCs here are sealed with rugged coverlays and tested to survive 10+ years of road abuse.

Today’s drivers expect screens, touch controls, and connectivity that rival their smartphones. FPCs make this possible:

- Curved displays and touchscreens: From 12-inch dashboards to rear-seat entertainment, curved screens require FPCs that bend with the glass, connecting pixels to processors without unsightly wires.

- Steering wheel controls: Buttons for cruise control, volume, or voice commands are mounted on curved, vibrating steering wheels. FPCs here are ultra-flexible, withstanding millions of presses and bends without failure.

EVs and hybrid vehicles rely on electric motors that need precise power management. FPCs play a key role:

Not all FPCs are built for cars. Automotive-grade FPCs must pass brutal tests to meet strict standards like IATF 16949 and ISO 26262 (functional safety):

- Vibration resistance: Tested to withstand 30g vibrations (10–2000Hz) for 1000+ hours—mimicking a lifetime of potholes and rough roads.

- Temperature cycling: Exposed to -40°C to 125°C for 1000+ cycles without delamination or signal loss.

- Chemical resistance: Survives exposure to oil, coolant, and road salt—substances that would corrode standard FPCs.

- Flame retardancy: Rated UL94 V-0 to prevent fire spread in case of electrical faults.

As cars evolve into autonomous, connected, and shared vehicles, FPCs will only grow more critical:

- Autonomous driving (L4/L5): Cars with full self-driving will need 50+ sensors, all connected via high-speed FPCs that handle terabytes of data daily.

- EV range optimization: Lighter FPCs will reduce vehicle weight, while more efficient designs will minimize energy loss in battery systems.

- Sustainability: FPCs use less copper and plastic than traditional harnesses, aligning with automakers’ goals to reduce carbon footprints.

Automotive FPCs may not grab headlines like electric motors or self-driving software, but they’re the glue that holds today’s tech-driven vehicles together. By solving problems of weight, space, reliability, and speed, they’ve become indispensable to automakers racing to build safer, smarter, and more efficient cars.

The next time you step into an EV, use adaptive cruise control, or tap a touchscreen in your car, remember: there’s an automotive FPC working behind the scenes, making it all possible. In the future of mobility, flexibility isn’t just an advantage—it’s a necessity.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.