From the moment you wake up to check your smartphone to the second you plug in your laptop at night, there’s an unsung hero ensuring every device stays powered: the battery flexible printed circuit (FPC). These thin, bendable circuits are the silent conductors that bridge batteries to screens, chips, and sensors—turning stored energy into the functionality we rely on. In a world obsessed with longer battery life, faster charging, and sleeker designs, battery FPCs are the unsung linchpins. Here’s why they matter more than you think.

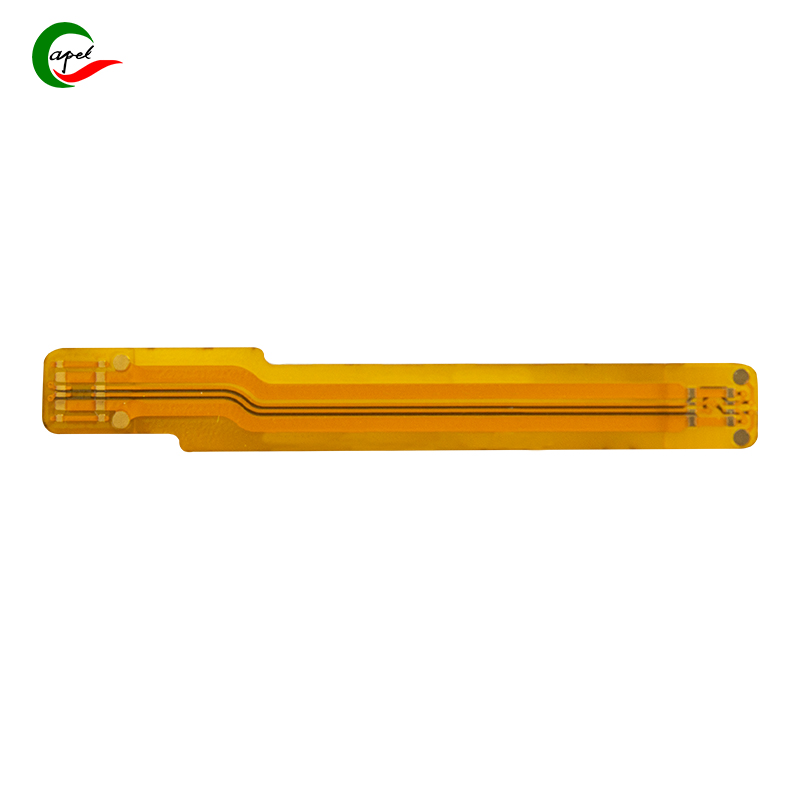

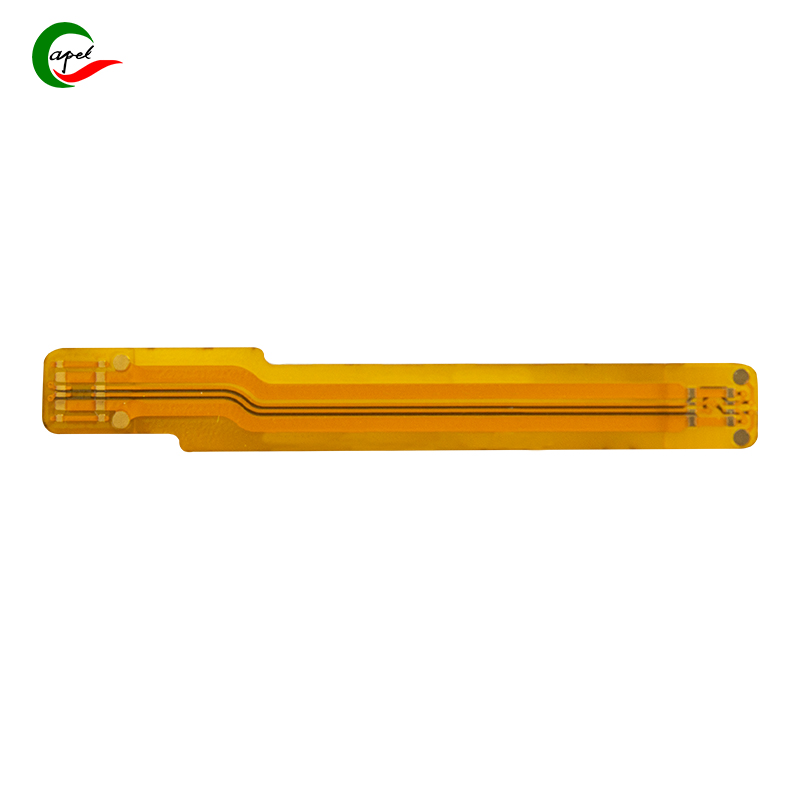

At its core, a battery FPC is a specialized flexible circuit designed to manage power flow between a device’s battery and its components. Unlike rigid PCBs, which are too bulky for slim devices, battery FPCs are made from lightweight materials like polyimide (PI) and ultra-thin copper foil, allowing them to fit into tight spaces—think the narrow gap between a phone’s battery and its frame or the curve of a smartwatch.

But they’re more than just "wires with flex." Modern battery FPCs integrate critical features:

- Power regulation: They carry current from the battery to the device while preventing overloads (via built-in fuses or protective circuits).

- Data transmission: Many also send real-time data—like battery temperature, charge level, or health status—to the device’s main chip (ever wondered how your phone knows it’s at 1%? Thank a battery FPC).

Space efficiency: Their flexibility lets them twist around corners or fold into compact areas, enabling the slim profiles of today’s laptops, earbuds, and tablets.

We demand more from our electronics than ever: thinner designs, faster charging, all-day battery life, and safety. Battery FPCs make all of this possible.

Remember the brick-sized cell phones of the 90s? Their batteries were large, and their rigid wiring harnesses took up half the device. Today’s 6.7-inch smartphones with 5000mAh batteries? Battery FPCs are the reason they fit in your pocket.

- Ultra-thin construction: Battery FPCs can be as thin as 0.1mm, freeing up space for larger batteries. For example, Apple’s AirPods use a tiny battery FPC that bends around the earbud’s internal components, allowing for a compact design without sacrificing battery capacity.

- Customizable shapes: Unlike rigid wires, FPCs can be laser-cut into precise patterns to fit unique device architectures. This is why foldable phones—with their complex hinges and curved batteries—rely on battery FPCs to maintain power flow even when bent 180 degrees.

Fast charging is no longer a luxury—it’s a expectation. But pushing more current through a device faster risks overheating or short circuits. Battery FPCs solve this with:

- High-conductivity copper: Premium battery FPCs use rolled copper foil (instead of cheaper electrolytic copper), which conducts electricity more efficiently. This allows them to handle higher currents (up to 10A in some fast-charging phones) without overheating.

- Built-in safety features: Many battery FPCs include thermal fuses or overcurrent protection (OCP) circuits. If the current spikes (say, due to a faulty charger), the FPC shuts down power flow to prevent fires—a critical safeguard in devices we carry in our pockets.

A battery’s lifespan depends on how well it’s managed. Battery FPCs act as "battery doctors," tracking vital stats:

- Temperature sensing: Lithium-ion batteries degrade quickly in extreme heat. Battery FPCs with embedded thermistors monitor temperature and send alerts to the device, which can slow charging or reduce performance to protect the battery.

- Charge cycle tracking: By counting charge/discharge cycles and measuring voltage drops, FPCs help devices estimate battery health (e.g., "Your battery can now hold 85% of its original capacity"). This data lets users know when it’s time to replace a battery—saving them from sudden shutdowns.

The explosion of IoT devices—from fitness trackers to smart home sensors—relies on battery FPCs to deliver power in tiny, flexible packages:

- Wearables: A fitness band’s battery is often smaller than a postage stamp. Its battery FPC must be flexible enough to bend with your wrist while delivering steady power to heart rate monitors and accelerometers.

- Medical devices: Insulin pumps and hearing aids use battery FPCs to fit into compact, body-safe designs. Their biocompatible materials (like PI) ensure they won’t irritate skin, even with 24/7 contact.

As devices evolve, so will battery FPCs. Here’s what’s next:

- Wireless charging integration: Future FPCs may combine power 传输 with wireless charging coils, eliminating the need for separate components in devices like smartwatches.

- Energy harvesting: Research is underway to add thin solar cells or kinetic energy harvesters to battery FPCs, allowing devices to recharge themselves from light or movement.

- AI-driven management: FPCs with tiny embedded chips could learn your usage patterns (e.g., "You charge your phone overnight") and adjust power flow to maximize battery life.

Battery FPCs may not be as flashy as a new chip or a foldable screen, but they’re the reason our devices work—reliably, safely, and efficiently. They’re the bridge between stored energy and usable power, the guardians of battery health, and the enablers of the sleek, powerful gadgets we can’t live without.

Next time you plug in your phone or check your smartwatch’s battery level, take a moment to appreciate the battery FPC: the unsung hero keeping our connected world running.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.