Date: 2026-02-15

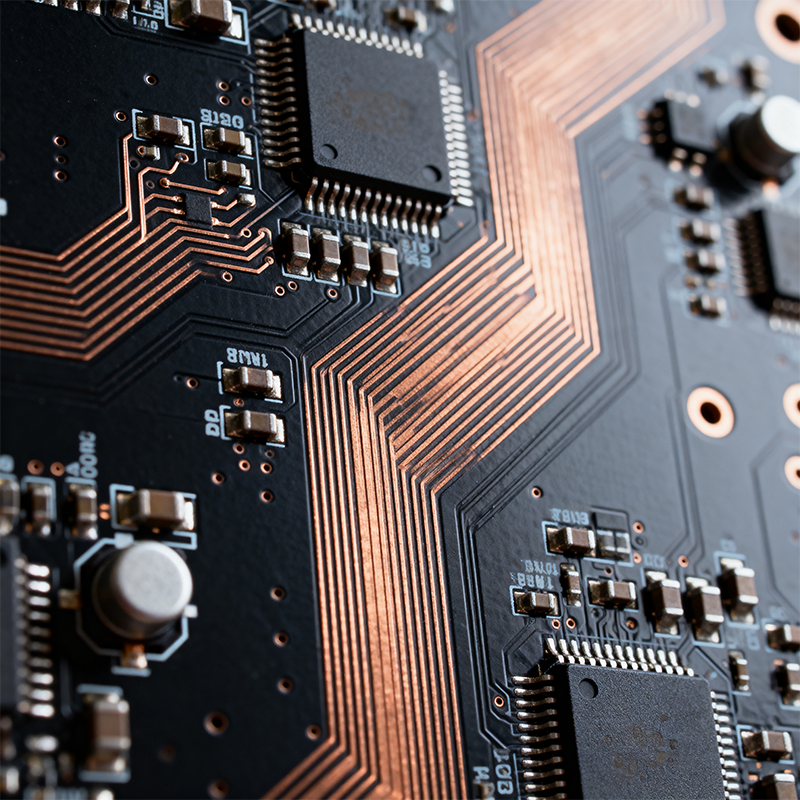

Inside a high-performance server rack, over 90% of data traffic converges and is routed through a special type of board—this is the backplane, the core backbone of modern electronic systems.

Imagine walking into the control tower of a major international airport, watching controllers orchestrate the safe, orderly takeoffs, landings, taxiing, and gate connections for hundreds of aircraft. In the world of electronic equipment, the backplane plays a similar role—it is the central hub for connection and routing inside large-scale electronic systems.

Unlike a standard circuit board, a backplane does not directly host processing chips. It is specifically designed to connect multiple functional daughter cards, distribute power, and transmit high-speed signals. From telecom switches and data center servers to medical imaging devices and industrial automation systems, any complex electronic equipment requiring modularity, scalability, and high reliability relies on backplane technology.

Simply put, a backplane is a highly specialized printed circuit board. Its primary function is to act as the "skeleton" or "main artery" of an electronic system, providing a stable physical mounting platform and reliable electrical connections for various functional cards (often called "daughter cards" or "blades").

Here's an analogy:

A Standard Motherboard: Is like a fully functional, standalone house where the kitchen, bedrooms, and living room are all built on the same foundation.

A Backplane System: Is like a modern, large-scale business park. The backplane is the park's main road network and central power grid, while the individual daughter cards are different, independent buildings within the park (office towers, data centers, labs). This architecture allows each "building" to be upgraded, repaired, or replaced independently without halting the entire "park's" operation.

The core value of a backplane lies in its modular design. Through standardized connectors (most commonly those conforming to VITA or PICMG standards), different processor cards, storage cards, I/O cards, and specialized accelerator cards can be plugged into the backplane like puzzle pieces, quickly forming a complete, complex system. This design极大地 enhances system flexibility, scalability, and maintainability.

A high-performance backplane is far from a passive board with rows of connectors. It is a meticulously engineered active interconnect platform that must协同 manage three core tasks:

1. High-Speed Signal Interconnection and Routing

This is the backplane's central challenge. In today's data centers, backplanes must transmit data at rates of hundreds of gigabits per second (Gb/s) or even terabits per second (Tb/s). As signals travel across the backplane's complex traces, they face issues like attenuation, crosstalk, and reflection. Therefore, modern backplane design must consider signal integrity much like designing a highway network:

Precise Impedance Control: Ensures each "lane" (signal trace) has consistent electrical properties to prevent signal "bumps."

Differential Pair Routing: Uses two phase-opposite traces to transmit one signal, resisting external interference like a "double insurance" for data.

Length Matching: For a single bus (like a DDR memory channel), ensures all signal traces are nearly identical in length, making data "arrive side-by-side."

2. High-Power, High-Purity Power Distribution

A chassis filled with high-performance compute and accelerator cards can have a total power draw of several kilowatts. The backplane must serve as a stable, efficient, and clean power distribution network. This involves:

Dedicated, Multi-Layer Power Planes: Using thick copper layers (e.g., 2 oz or more) to carry high current, minimizing loss and heat.

Decoupling Capacitor Networks: Placing numerous capacitors near each daughter card connector acts like "small reservoirs" to instantly meet a chip's sudden power demands and filter power supply noise.

Power Sequencing: Ensuring different voltage rails power up and down in the correct order to protect sensitive semiconductor devices.

3. Structural Rigidity and Thermal Management Support

The backplane is often the most robust mechanical component in an entire chassis or rack. It must:

Provide Solid Support: Withstand the insertion/removal forces and long-term vibration from dozens of heavy daughter cards.

Aid in Heat Dissipation: Its layered structure and internal copper planes act as a massive thermal conductor. Advanced designs incorporate thermal vias or metal core substrates to help transfer heat from the daughter cards to the chassis walls.

Backplane technology has undergone significant evolution, driven by an insatiable demand for higher bandwidth and simpler architectures.

The Old Era: Parallel Bus Architecture

Early backplanes (e.g., based on PCI or VME buses) used a parallel architecture. Data bits were transmitted simultaneously across multiple parallel traces (e.g., 32 or 64 bits). This was like using a convoy of trucks to move goods. While simple, as speeds increased, timing differences (skew) between traces became hard to control, causing the "convoy" to arrive out of sync, limiting bandwidth and distance.

The Modern Era: High-Speed Serial Interconnect

Modern backplanes have almost entirely shifted to high-speed serial interconnects like PCI Express, Ethernet, and Infiniband. This technology packages data and transmits it serially at extremely high clock frequencies over a pair of differential traces (Tx and Rx). It's like loading goods onto a high-speed train sent continuously down a single track. The advantages are enormous:

Fewer Pins, Smaller Connectors: Simplifies backplane and card design.

Massive Bandwidth Potential: Bandwidth scales easily by increasing per-lane data rates (from PCIe 3.0's 8 GT/s to PCIe 6.0's 64 GT/s) and adding more lanes.

Strong Noise Immunity: Differential signaling and embedded clock technology provide excellent signal integrity.

To combat the attenuation of serial signals over the long distances on a backplane, modern designs often need to integrate signal conditioning components like retimers or redrivers. These act like "gas stations" and "signal boosters" on a highway, repairing and amplifying weakened signals to ensure data arrives error-free.

Manufacturing a backplane that reliably operates at high speeds is one of the ultimate tests of PCB design and fabrication capability.

Material Science: Standard FR-4 material exhibits excessive loss at frequencies above a few GHz. High-speed backplanes must use low-loss dielectric materials like Rogers, MEGTRON 6/7, or Tachyon. These materials have more stable, lower dielectric constants and dissipation factors but come at a significantly higher cost.

High-Density Interconnect: To route thousands of high-speed signal connections within a limited board area, backplanes typically employ extremely complex stack-ups of 20 layers or more. This requires advanced HDI processes like laser drilling, microvias, and back-drilling to control via stubs and minimize signal reflections.

Rigorous Testing and Validation: Testing can constitute a significant portion of a backplane's total cost. Beyond basic electrical testing, comprehensive Signal Integrity testing is mandatory. Tools like Time Domain Reflectometers and Vector Network Analyzers are used to verify that impedance, crosstalk, and attenuation match simulation models. Only after passing all these parameters can a backplane proceed to system integration.

Backplane technology is the unsung hero behind the infrastructure of many critical industries:

Data Centers & Cloud Computing: The largest market for backplanes. The core of Top-of-Rack (TOR) switches, server nodes, and storage arrays relies on backplanes, which determine the efficiency and ceiling of intra-rack data exchange.

Telecommunications & Networking: From 5G baseband units to core network routers, backplanes provide the high-speed data switching capability between various line cards, acting as the "crossroads" for network traffic.

Defense & Aerospace: In these fields with extreme demands for reliability and ruggedness, backplanes employ hardened designs using special materials and connectors to withstand severe shock, vibration, and wide temperature ranges.

Industrial Automation & Test & Measurement: In modular test systems or large industrial control cabinets, backplanes provide a unified integration platform for various data acquisition, control, and communication cards.

Facing the challenges of future computing and data deluge, backplane technology is evolving in two key directions:

Pushing the Limits of Electrical Board-Level Interconnects: As per-lane electrical signaling rates approach physical limits (constrained by material loss and connector performance), next-generation systems are exploring co-packaging optical engines with switch chips near the backplane, with a long-term path towards on-board optical modules or all-optical backplanes. Optical signals, with near-zero loss and no electromagnetic interference, represent the ultimate path to breaking intra-rack bandwidth bottlenecks.

Smarter "Active" Backplanes: Future backplanes may integrate microcontrollers and sensors to enable intelligent power management, health monitoring, and predictive failure analysis. They could actively regulate power to different slots, report connector mating cycles and contact resistance, or even guide cooling fans to target hotspots precisely, evolving into an intelligent system management platform.

The backplane, this silent backbone hidden within the chassis, is an engineering marvel that connects individual computing units to build vast digital systems. It represents the evolution of electronic systems from single-function devices towards modular, scalable, and highly reliable complex architectures. For electronic equipment manufacturers, a deep understanding of backplane technology equates to mastering a key capability for building high-end integrated systems. In a data-driven era, the width, speed, and reliability of this "backbone highway" will directly determine the performance ceiling of the applications it supports.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..