Date: 2026-02-16

Imagine a chip the size of your fingernail, its entire functionality locked behind a grid of hundreds of connections finer than a human hair. How do engineers unlock its potential for testing, prototyping, and integration without multi-million dollar equipment? The answer lies in a deceptively simple tool: the breakout board.

In the electronics world, a persistent gap exists between cutting-edge chip design and practical engineering work. Integrated circuit packages are shrinking to astonishing densities, while development benches, test equipment, and production lines still rely on robust, human-scale connections. Breakout boards exist solely to close this gap. They act as critical physical translators, converting a chip's microscopic, inaccessible interface into a landscape of standard, workable connection points. Without them, developing with or testing many modern components would be prohibitively difficult, expensive, or outright impossible.

At its core, a breakout board is a specialized, small-form-factor printed circuit board (PCB). Its sole purpose is to reroute the dense, fine-pitched connections of a modern electronic component to a set of accessible, standard-sized pads or pins.

You can think of it through several analogies:

The Chip's "Developer Interface": Just as software developers use an IDE to interact with complex code, hardware engineers use a breakout board to interact with a complex chip's pins.

A Precision Adapter: It functions like a high-tech version of a travel plug adapter, solving a physical compatibility problem between two different "connection languages."

A Micro-to-Macro Converter: It takes the micro-scale world of surface-mount technology (SMT) and translates it into the macro-scale world of through-hole prototyping.

A standard breakout board has one side designed to mate precisely with the target component—be it a Ball Grid Array (BGA), Quad Flat No-lead (QFN) package, or a flexible cable connector. The other side presents these connections as a simple array of through-hole pads, pin headers (often with a standard 0.1-inch/2.54 mm pitch), or common connectors. This fundamental act of routing and fanning out connections is what gives the breakout board its name.

Breakout boards are not just convenient; they are often essential for efficient and safe electronics development and manufacturing. Their value manifests in four key areas:

1. Accelerating Prototyping and Development

Soldering a delicate, high-pin-count chip directly to a custom PCB for initial testing is a high-risk gamble. A design flaw could mean destroying the expensive chip during de-soldering. A breakout board allows engineers to securely mount the chip once and then treat it as a pluggable module. They can insert it into breadboards, clip test leads onto its headers, and iterate on circuits rapidly without risking the core component. This can shave weeks off development cycles.

2. Enabling Practical Testing and Debugging

On a finished product's densely packed motherboard, most chip pins are electrically invisible, buried between layers of the PCB. How do you probe a specific signal with an oscilloscope? A breakout board brings every critical pin out to an exposed test point. This is invaluable for validating signal integrity, measuring power quality, and diagnosing faults during hardware bring-up and validation.

3. Facilitating Low-Volume Integration

Sometimes, you need to incorporate a new, advanced chip into an existing system or a low-volume prototype where designing a custom motherboard is not justified. A breakout board serves as a perfect, cost-effective intermediary. It allows a surface-mount chip to be treated like a through-hole component, enabling integration that would otherwise be impractical.

4. Simplifying Manufacturing and Handling

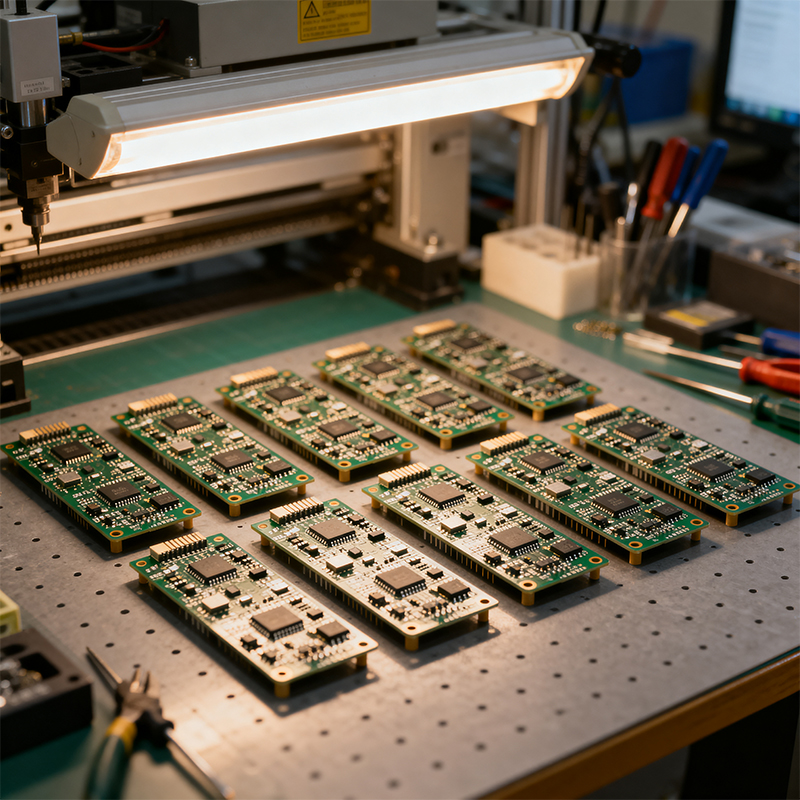

For small production runs, manually soldering intricate components requires great skill and has a high defect rate. Pre-soldering chips onto breakout boards in a controlled factory environment creates robust sub-modules. Assembly technicians can then simply plug these pre-validated modules into a larger board, dramatically simplifying the final assembly process and improving overall yield.

Breakout boards come in various forms, tailored to specific tasks:

For IC Packages:

BGA Breakout Boards: Essential for processors, FPGAs, and advanced memory. They provide access to the array of solder balls underneath the chip.

QFN/DFN Breakout Boards: Used for chips with perimeter pads and a large thermal pad on the bottom. They provide electrical access and often a thermal path for a heatsink.

Fine-Pitch Breakout Boards: Target chips with very closely spaced leads (e.g., TQFP, LQFP), making them solderable and probe-able.

For Modules & Connectors:

Cable & Connector Adapters: Break out the pins of a board-to-board connector, a flexible flat cable (FFC), or a miniature coaxial port into standard headers.

Module Carrier Boards: Allow complete pre-built modules (e.g., a wireless communications module) to be mounted and connected more easily on a prototyping board.

Advanced / Active Boards:

Signal Conditioning Boards: These include basic circuitry like level shifters (translating 1.8V logic to 5V), power regulators, or filter networks, providing a ready-to-use interface for a sensitive chip.

Protocol Adapters: Some breakout boards include active components to handle specific communication protocols (like converting a parallel interface to SPI), simplifying software development.

A well-designed breakout board is more than a simple spiderweb of traces. Good design is guided by several principles:

Signal Integrity is Paramount: Traces carrying high-speed or sensitive signals must be kept short, direct, and properly impedance-controlled where necessary. Good power and ground plane design is crucial to minimize noise.

Power Delivery Must Be Robust: The board must provide low-resistance paths for power and ground. Ample space for decoupling capacitors near the chip's power pins is non-negotiable for stable operation.

Don't Forget Thermal Management: If the chip dissipates significant heat, the board should incorporate thermal vias, copper pours, and mounting points to attach a heatsink, preventing thermal throttling or damage during testing.

Design for Usability: Clear, legible silkscreen labels for every pin are essential. Grouping related signals (all power pins, all ground pins, data buses) logically helps prevent wiring errors. A thoughtful pinout can save hours of debugging frustration.

Balance Performance with Cost: Use the simplest PCB stack-up (number of layers) and most common materials (like FR-4) that satisfy the electrical and thermal requirements. This keeps costs low and turn-around times fast.

The Embedded Developer: Quickly tests a new 32-bit microcontroller's peripherals by wiring its breakout board to sensors and displays on a breadboard, long before the final PCB is manufactured.

The Validation Engineer: Characterizes the performance of a new switching voltage regulator by soldering it to a breakout board with dedicated sense points, allowing precise measurement of efficiency and ripple.

The Educator or Maker: Demystifies complex components. Instead of a "black box" sensor module, students use a breakout board to access each pin of the core sensor IC, learning how to interface with it directly through hands-on experimentation.

The humble breakout board is evolving alongside the components it serves:

Integration of Active Diagnostics: Future boards may incorporate LED indicators, test points connected to buffer amplifiers, or even simple logic analyzers to provide immediate visual or electrical feedback during debugging.

Support for Extreme Performance: As data rates push into the hundreds of gigabits per second, breakout boards for these interfaces will resemble high-frequency RF substrates, with meticulous attention to material loss, impedance, and connector quality.

The Rise of Instant Customization: Cloud-based PCB design tools and quick-turn manufacturers are making it feasible to design, order, and receive a custom breakout board for a newly released chip within days, greatly accelerating the pace of innovation.

The breakout board is a fundamental tool of electronic innovation, a quiet enabler that sits at the crossroads of component technology and practical engineering. It reduces risk, saves time, and lowers the barrier to working with advanced electronics. For any company designing or manufacturing electronic devices, understanding and utilizing breakout boards is not a mere technical detail—it's a strategic practice that enhances agility, improves product quality, and accelerates time-to-market in an increasingly fast-paced technological world.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..