If you’ve ever taken apart a small device—like a wireless earbud or smartwatch—you’ve probably seen flexible PCBs: thin, bendable circuits that are almost always brown or clear. But here’s a question you might not have asked: Can they be made in other colors? The short answer is yes—but how, and why would you want them to be? Let’s break this down simply, no confusing jargon, just straight facts.

Flexible PCBs aren’t stuck with brown—their color comes from two key parts of their design, both of which can be customized. Here’s how it works:

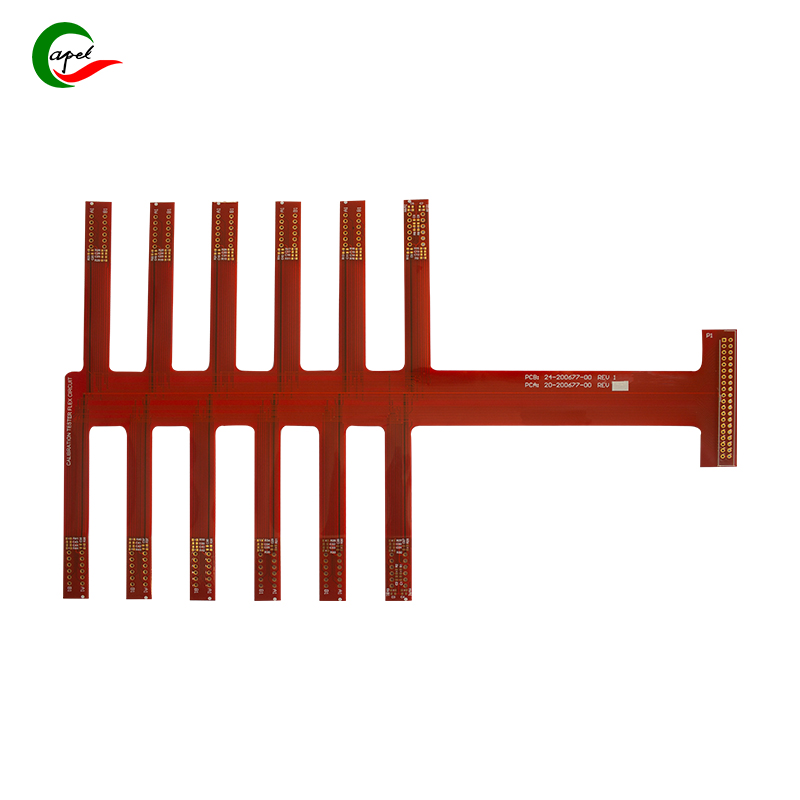

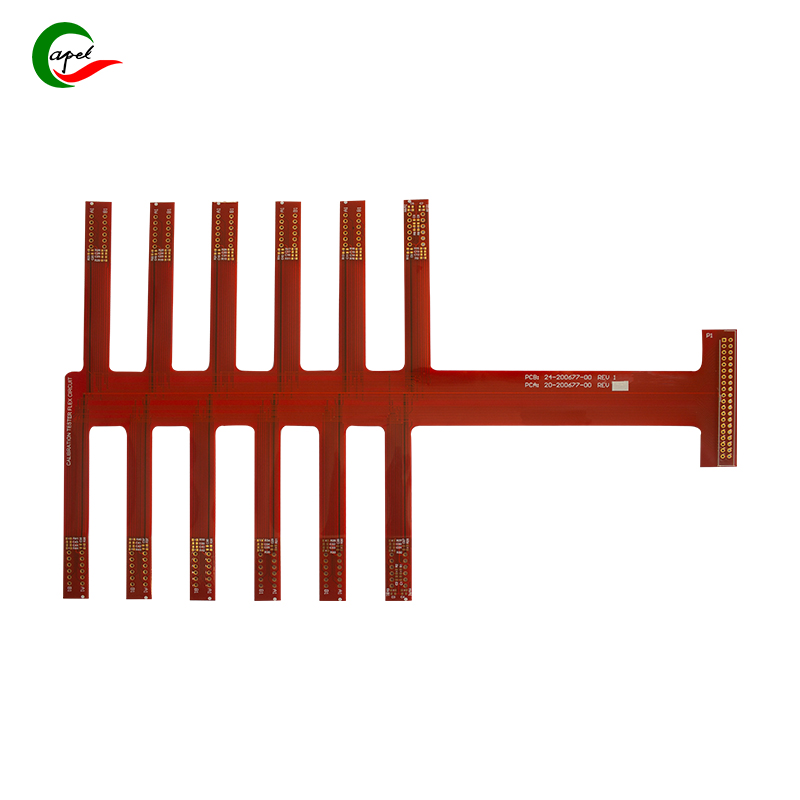

The “solder mask” is a thin, protective layer on top of the flexible PCB. Its main job is to shield the tiny copper circuits from dust, moisture, and accidental short circuits. On rigid PCBs, this layer is usually green—but on flexible PCBs, it can be almost any color you can think of: black, blue, red, white, even custom shades like a brand’s signature color.

-

How it’s done: Factories apply a colored, heat-curable ink to the surface of the flexible PCB. The ink dries into a flexible film that doesn’t crack when the PCB bends (unlike rigid ink, which would break).

-

Example: A high-end fitness tracker might use a black solder mask on its flexible PCB to match the tracker’s sleek, dark design. This hides the brown copper circuits, making the inside of the device look cleaner.

The “substrate” is the base of the flexible PCB—the bendable material that holds the copper circuits (usually a plastic called polyimide). By default, this substrate is brown, but it can be dyed during manufacturing to other colors.

-

Catch: Colored substrates are more limited than colored solder masks. Bright or neon dyes can weaken the polyimide’s flexibility—so you’ll mostly see neutral colors like black, white, or gray here.

-

Use case: Medical devices (like a flexible sensor for a heart monitor) might use a white substrate. The white color reflects light, making it easier for technicians to spot small components or defects during assembly.

You might think coloring a flexible PCB is just for aesthetics—but there are practical reasons too. Here are the three biggest ones:

For premium devices, every detail matters—including the inside. A colored flexible PCB can match a brand’s identity or the device’s design:

Devices with multiple flexible PCBs (like foldable phones or laptops) can get confusing to work on. Coloring each PCB a different color helps technicians tell them apart quickly:

-

Example: A foldable phone might have 5 flexible PCBs: one for the main screen (red), one for the secondary screen (blue), one for the battery (black), one for the camera (white), and one for the charging port (gray). When repairing the phone, a technician can instantly grab the right PCB without checking labels.

-

Why it matters: It saves time and reduces mistakes. Mixing up PCBs could break the device or cause safety issues (like connecting a battery PCB to a screen circuit).

In some cases, color serves a practical purpose beyond looks or identification:

-

Light reflection: White substrates or solder masks reflect light, which helps in devices with LEDs (like a smartwatch’s display) by reducing glare on the PCB.

-

Heat absorption: Black solder masks absorb more heat than light colors. This can be useful in small devices (like a wireless earbud) where heat needs to be distributed evenly instead of reflected back onto components.

While flexible PCBs can be colored, there are some rules and drawbacks to keep in mind:

Bright, neon colors (like hot pink or electric green) are rare because:

-

The dyes needed for these colors can make the solder mask or substrate less flexible. A neon pink solder mask might crack when the PCB bends, exposing the copper circuits.

-

Some dyes fade when exposed to heat (over 80°C) or sunlight. This is a problem for devices that get hot, like car sensors or laptop hinges.

Coloring a flexible PCB isn’t free. Custom colors or rare shades require special inks or dyes, which can add 5–10% to the cost of the PCB. For mass-produced devices (like budget smartphones), this extra cost might not be worth it—so they stick with standard brown or green.

A colored flexible PCB works exactly like a brown one. The color doesn’t change how well it conducts electricity, how bendable it is, or how long it lasts. It’s purely a design or functional choice, not a performance upgrade.

Flexible PCBs don’t have to be brown—they can be colored to match a brand, make repairs easier, or even serve small functional roles. While there are limitations (cost, color options), they’re a great way to add value to devices where details matter. Next time you open up a premium gadget, take a look—chances are, its flexible PCBs are colored for a reason.

related link: