Date: 2026-01-20

Let’s talk about a scenario you might have faced: your latest design runs hot. We’re not talking a little warm—we’re talking about power modules, high-brightness LED arrays, or RF components that turn a standard circuit board into a tiny toaster oven. You’ve tried adding heat sinks and fans, but the core problem remains: the board itself is insulating the heat, not getting rid of it.

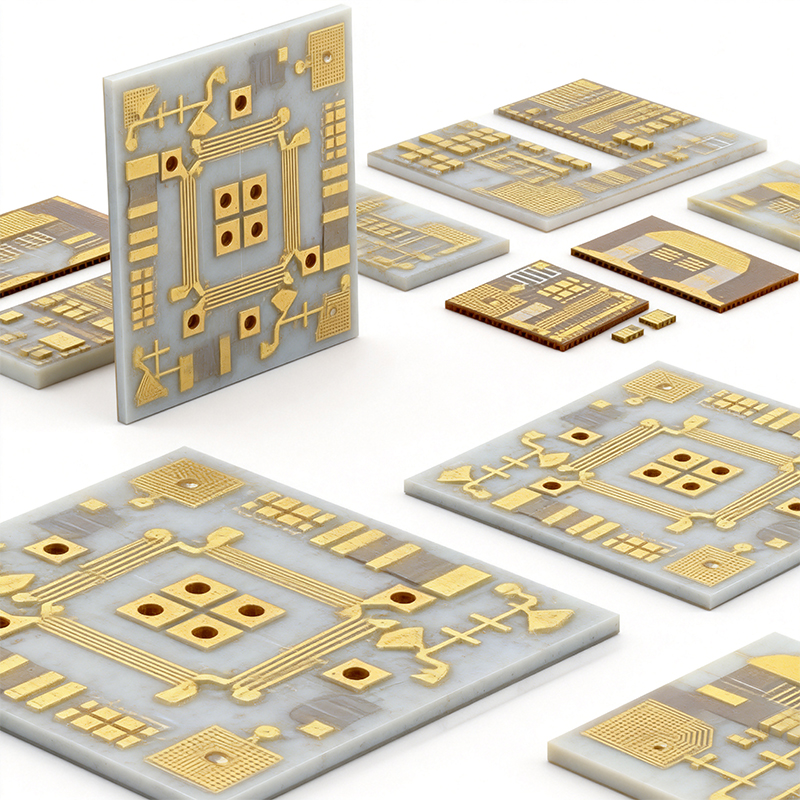

This is where the conversation shifts from standard FR4 boards to a different league of materials. Enter the ceramic PCB board.

In simple terms, it’s a circuit board where the insulating base layer—the substrate—is made of ceramic, not the standard glass-reinforced epoxy (FR4) or other plastics.

Think of it this way:

A standard FR4 board is like plywood. It’s a great, cost-effective insulator and structural base for most applications.

A ceramic PCB board is like a high-tech ceramic tile used on a space shuttle’s hull. It’s incredibly hard, handles wild temperature swings without flinching, and conducts heat away brilliantly.

The most common types you’ll encounter are:

Alumina (Al₂O₃): The workhorse. Offers a great balance of thermal performance, electrical insulation, and cost.

Aluminum Nitride (AlN): The premium choice for extreme thermal conductivity—it’s like a superhighway for heat.

Beryllium Oxide (BeO): Has exceptional thermal properties but is avoided now due to toxicity risks during machining.

Ceramic PCBs aren’t for your average project. They solve specific, tough problems:

Extreme Heat Dissipation: This is the #1 reason. Ceramic materials conduct heat 5 to 10 times better than FR4. They pull heat away from hot components (like power transistors or laser diodes) and spread it across the board, preventing a single hot spot from killing your device.

High-Frequency & RF Performance: At radio and microwave frequencies, signal loss in the substrate matters. Ceramics offer lower loss and more stable electrical properties than FR4, meaning your signals stay cleaner and stronger.

Brutal Environments: Need a board that won’t warp, degrade, or absorb moisture under high heat, corrosive conditions, or thermal cycling? Ceramic’s inherent stability makes it the go-to for automotive under-hood electronics, aerospace, and down-hole drilling equipment.

Size Constraints: Because ceramic is such an effective heat spreader, you can often reduce or eliminate bulky external heat sinks, leading to more compact packaging.

Ceramic PCB technology is powerful, but it comes with its own set of rules:

Cost: The raw materials and specialized manufacturing processes make ceramic boards significantly more expensive than their FR4 counterparts.

Fragility & Size Limits: While very hard, ceramic boards are more brittle than flexible FR4. They can be prone to cracking under mechanical stress, and the panel sizes are typically smaller.

Complex Assembly: The thermal properties that make ceramics great also mean your standard soldering profiles might not work. The assembly process (SMT) requires careful tuning to ensure proper solder joint formation without stressing the board.

This is the most important part. Moving to ceramic PCBs isn’t just a component swap; it’s a fundamental shift in your manufacturing approach. You need a partner who understands both the material science and the assembly challenges.

This is where a partner with deep, integrated manufacturing expertise becomes invaluable. A company like Kaboer, which operates its own advanced PCBA factory in Shenzhen’s electronics ecosystem, is positioned to bridge this gap effectively.

Working with an integrated partner means:

Seamless DFM Feedback: Their engineers can advise on ceramic-specific design rules—trace widths, via designs, and layout for thermal expansion—from the start, preventing costly revisions.

Process Harmony: They can fine-tune the entire chain, from substrate sourcing and metallization to the precise SMT reflow profile needed for your specific ceramic board. This coordination is hard to achieve when PCB fabrication and assembly are split between two vendors.

Unified Responsibility: With fabrication and assembly under one roof, there’s no finger-pointing. Any issue, from a plating defect to a soldering quirk, is owned and solved by one team focused on your board’s success.

Ask yourself:

Is heat management the primary limiting factor in my design’s reliability or performance?

Am I working with high-power densities or high-frequency signals (>1 GHz)?

Does my product need to survive in a harsh, high-temperature environment?

If you answered “yes” to any of these, then exploring ceramic PCB technology is a smart engineering move. It’s a strategic investment in reliability and performance for applications where standard boards simply hit their limits.

The key to success lies in partnering with a manufacturer who doesn’t just see a ceramic board as a special item, but as a complex system requiring coordinated expertise from design to delivery.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..