Date: 2026-01-20

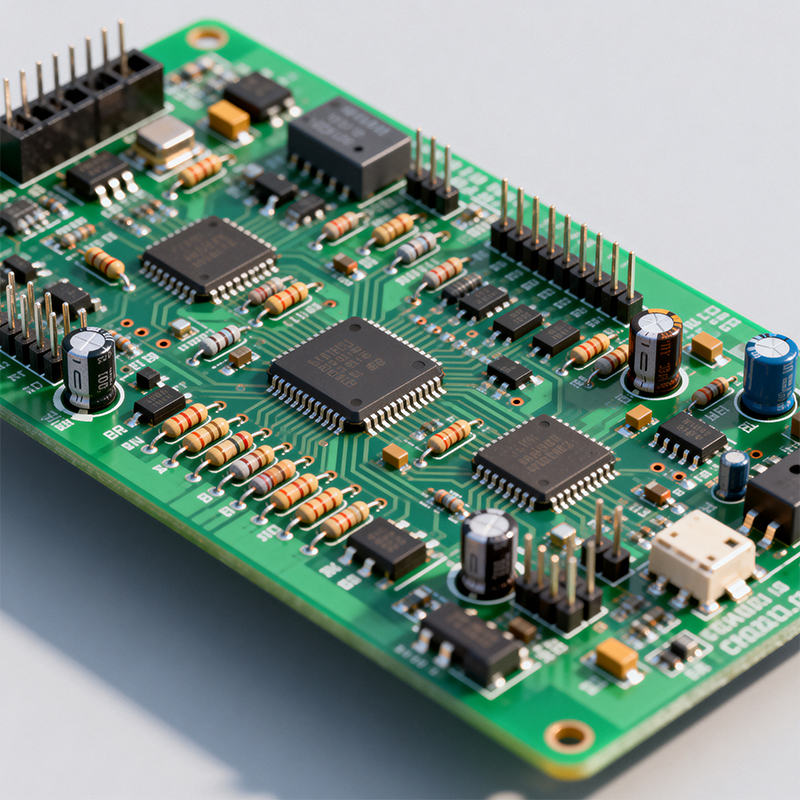

You've sent off your PCB design files. A few weeks later, a box arrives with finished, assembled boards. But what actually happened in between? For anyone sourcing electronics, understanding the journey—the surface mount PCB assembly line—isn't just academic. It’s the key to predicting quality, troubleshooting issues, and choosing the right manufacturing partner.

Let's walk through a modern SMT line, not as a list of machines, but as a series of critical steps where small details make or break your product.

Think of this as laying down the exact blueprint for connections. A stainless steel stencil, laser-cut with holes matching your board’s pads, is aligned over the PCB. Solder paste—a sticky mixture of microscopic solder balls and flux—is swept across it, filling the holes.

Why this step matters more than you think:

Too little paste, and you get a weak connection. Too much, and you risk short circuits between tiny pins. The quality of this print sets the stage for everything that follows. Factories that skimp here by using worn stencils or poorly managed paste are building on a shaky foundation.

This is the star of the show. A pick-and-place machine, armed with a library of your components on reels and trays, goes to work. Its nozzles pick up parts—from massive chips down to spec-sized resistors—and place them onto the wet solder paste with breathtaking speed and precision.

The nuance isn't in the speed, but in the setup:

A machine is only as good as its programming and feeder calibration. Is the component library accurate? Are the feeders advancing tape correctly? This is where experienced technicians prevent a catastrophic "pile-up" of mis-picked parts or chronic misalignment.

The boards then glide into the reflow oven, a long tunnel with carefully engineered temperature zones. This isn't just "heating it up." It’s a precise thermal profile:

Preheat: Gradually raises temperature to activate the flux.

Soak: Allows the entire board to reach an even heat.

Reflow: A brief spike above the solder’s melting point, causing it to flow and form a metallurgical bond.

Cooling: A controlled solidification to create strong, shiny solder joints.

The magic word is profile:

Your specific board—with its mix of large and small components, dense and sparse areas—needs its own thermal recipe. An oven running a generic profile can overheat sensitive parts or under-heat large ones, leading to hidden defects.

After the oven, the board must be scrutinized. This is where Automated Optical Inspection (AOI) comes in. Cameras scan the board from multiple angles, comparing thousands of points to your original design files.

Inspection is your safety net:

It catches missing components, misalignments, and soldering defects like bridges or insufficient solder. A robust AOI program, with well-tuned acceptance criteria, is what separates a factory that finds problems on its line from one that lets problems ship to you.

Any factory with capital can buy an SMT line. What makes the difference for your project is the context and expertise wrapped around those machines.

This is where a company’s structure and location come into play. Take Kaboer, for example. Operating our own assembly factory in Shenzhen isn’t just a line on a spec sheet. It means our engineering team is on the floor, not in a distant office. They see how a particular chip’s footprint might hold paste differently, or how a specific board shape affects the thermal profile in the oven.

For you, this translates to a few tangible benefits:

Fewer "Surprises": Proactive Design for Manufacturability (DFM) feedback comes from people who run the machines daily, not from a theoretical checklist.

Agility: When a component sourcing issue arises (and they always do), being in Shenzhen’s supply chain epicenter means more options and faster pivots.

Accountability: With the entire process under one roof, there’s no passing the buck between a board fab and an assembler. The team that builds the board owns the outcome.

Surface mount PCB assembly is a symphony of precision engineering, chemistry, and vigilant quality control. When it’s done well, it’s invisible—your boards just arrive, working perfectly.

As a manufacturer, your job is to look beyond the brochure photos of shiny equipment. Ask about process control: How do you qualify and manage your solder paste? Who creates and validates your reflow profiles? What’s your AOI escape rate?

The answers will tell you if you’ve found a simple board-stuffing vendor, or a true manufacturing partner equipped to bring your careful design to life with the reliability it deserves.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..