Date: 2026-01-31

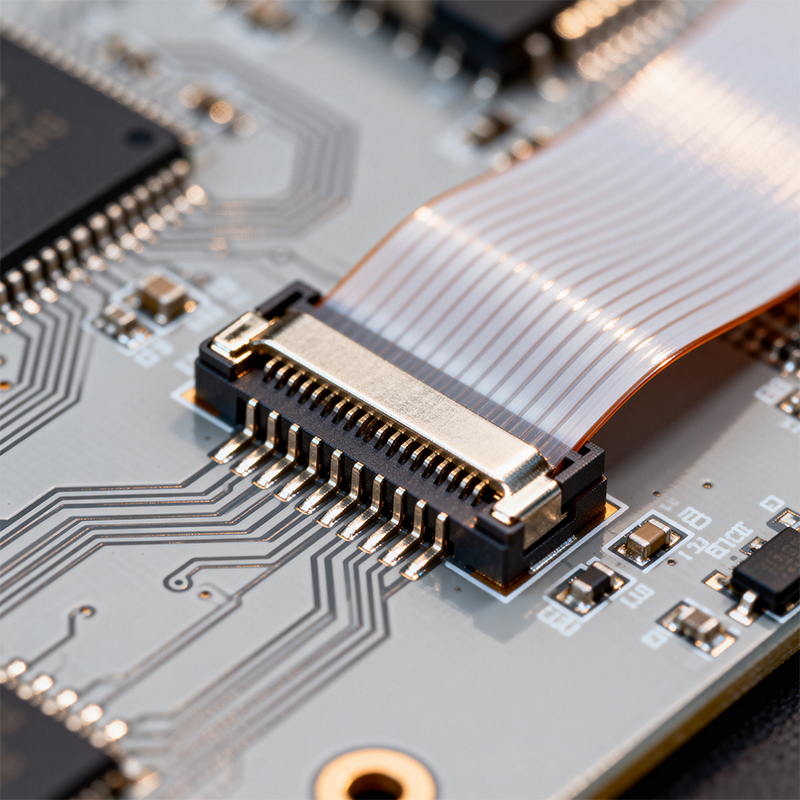

For electronic products that require complex three-dimensional wiring in compact spaces, flex-rigid PCB technology is a key enabler. It ingeniously integrates stable rigid sections and bendable flexible circuits into a single board, eliminating the need for connectors and cables. This significantly enhances device reliability, saves space, and reduces weight.

However, not every PCB factory is capable of handling this sophisticated process. Selecting a suitable flex-rigid PCB manufacturer is far more complex than choosing a standard PCB supplier. You need a true partner with deep process expertise and engineering collaboration capabilities.

Ultimate Reliability: By eliminating external connectors and wire harnesses, it removes common points of failure. The monolithic structure better withstands vibration, shock, and repeated flexing, making it ideal for demanding applications in medical, automotive, and aerospace fields.

3D Design Freedom: Engineers can design circuits like mechanical parts, allowing the board to bend and fold to fit perfectly into irregular product interiors, enabling unprecedented miniaturization and integration.

Simplified Final Assembly: As a complete subsystem, it greatly streamlines the final product assembly process, reducing overall labor costs and the potential for errors.

Given the process complexity, focus on the following core competencies:

First, Assess Engineering Support and Collaboration Depth. A superior manufacturer should engage early in the design phase, providing substantive Design for Manufacturability analysis. They need to review your stack-up, bend radii, and stress management in transition zones, offering expert advice to prevent costly issues during production.

Second, Examine Material and Process Expertise. Flex-rigid PCBs involve the combined use of various materials (like different polyimide types, adhesives, and rigid laminates). The manufacturer must deeply understand how these materials match in terms of thermal expansion, flexibility, and adhesion to ensure long-term reliability. Critical processes include delamination-free lamination, reinforcement of transition areas, and proper coverlay application on flex sections.

Third, Verify Quality and Reliability Testing. Beyond basic electrical tests, does the manufacturer offer targeted validation? Tests like flex cycling and thermal shock are crucial for guaranteeing stable performance throughout the product's intended lifespan.

Fourth, Confirm One-Stop Service Capability. An ideal manufacturer should provide end-to-end service from flex-rigid PCB fabrication to high-precision component assembly. This ensures the design intent is fully and consistently realized in the final product, avoiding quality risks and communication overhead associated with managing multiple vendors.

At Shenzhen Kaboer Technology, we understand that choosing a flex-rigid PCB manufacturer is a strategic decision. We are more than a supplier; we are an extension of your design team, committed to transforming complex designs into stable and reliable products.

Our value lies in integrated, end-to-end focus:

Deep Collaborative Design: Our engineers are ready to collaborate from the concept stage, working together to optimize your design for both innovation and manufacturability.

Proven Process Assurance: With mature experience in multilayer flex-rigid PCB manufacturing, we strictly control every step from material sourcing to precision lamination, serving industrial, medical, and consumer electronics brands with high-reliability requirements.

Board-to-Box一站式 Delivery: As a manufacturer with our own advanced PCBA factory, we seamlessly bridge flex-rigid board production with subsequent component assembly, testing, and packaging. This vertical integration offers you single-point accountability, unified quality standards, and faster time-to-market.

If you are looking for a manufacturing partner who thoroughly understands the challenges of flex-rigid PCBs and can deliver reliable solutions, Kaboer Technology is ready. Contact us today to discuss how we can help bring your innovative design to life with confidence.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..